Fabricated frame structure beam-column connection node and construction method

A frame structure, beam-column connection technology, applied in the direction of building structure, construction, building materials processing, etc., can solve the problems of restricting the development level of prefabricated structures, the quality of cast-in-place joints is difficult to guarantee, and the installation and replacement of components are difficult. Achieve the effects of low maintenance difficulty, prevent automatic loosening, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

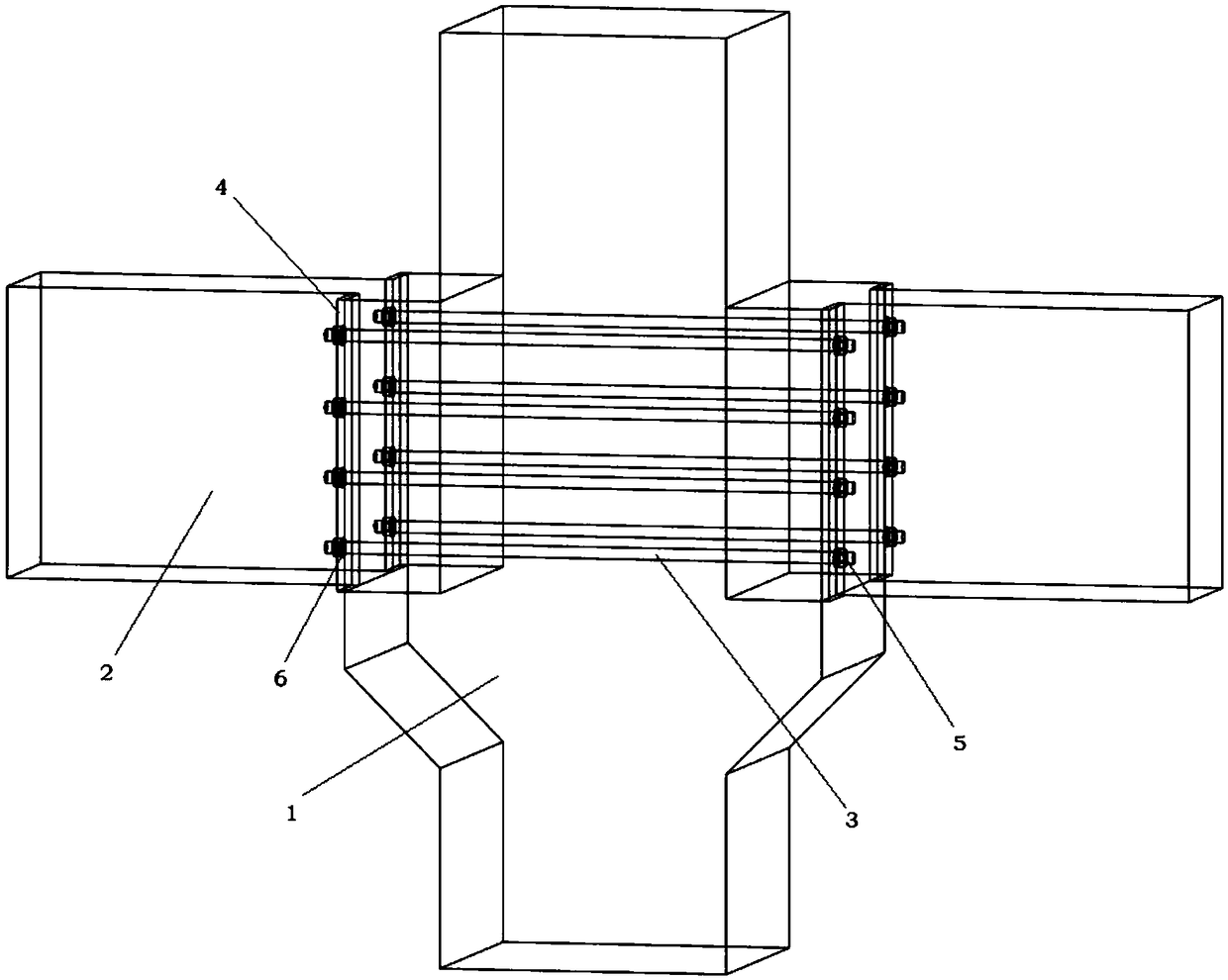

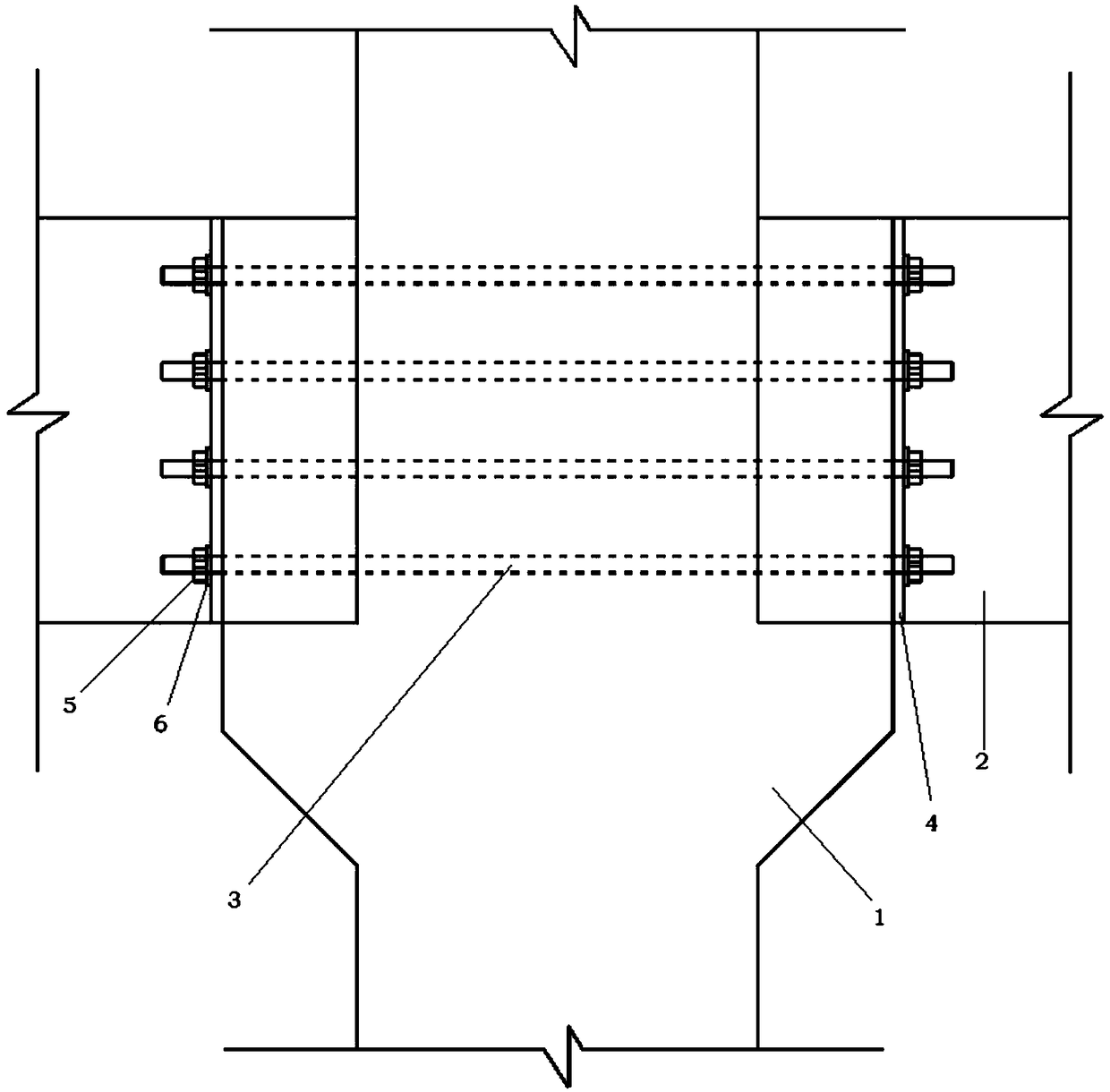

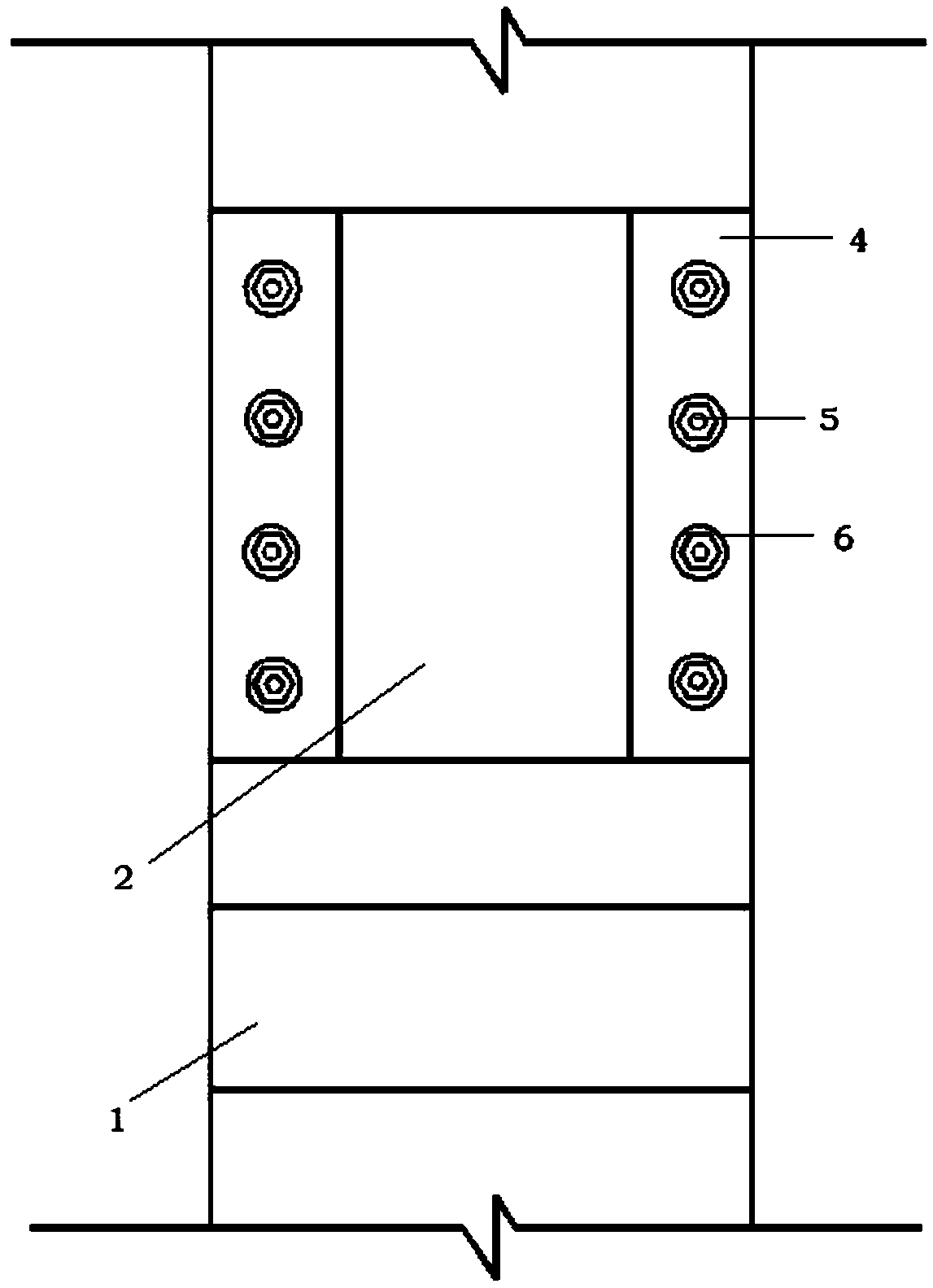

[0035] Such as Figure 1-4 As shown, this embodiment provides a beam-column connection node of an assembled frame structure, including a prefabricated corbel column 1, a prefabricated beam 2, a high-strength bolt 3, a pressure-bearing steel plate 4 and a nut 5; the prefabricated beam 2 includes a main body and a connecting part , the connection part is located at the end of the main body, integrally formed with the main body, and the cross-sectional area of the connection part is larger than the main body, thereby forming a force application surface opposite to the end surface of the prefabricated beam 2 on the connection part; the pressure bearing steel plate 4 is arranged on the force application surface, The connection part is supported by the corbels on both sides of the corbel column, and the connection part and the corbel column are connected by high-strength bolts 3 , and the ends of high-strength bolts 3 pass through the pressure-bearing steel plate 4 and are tightene...

Embodiment 2

[0037] Such as Figure 1-4 As shown, this embodiment is an embodiment improved on the basis of Embodiment 1, which includes all the content of Embodiment 1, that is, the beam-column connection node of the fabricated frame structure in this embodiment includes all the structures of Embodiment 1 Features, the specific improvements are as follows:

[0038] The prefabricated beam 2 is a T-shaped variable-section beam, that is, the main body of the prefabricated beam 2 and the connection part of the prefabricated beam 2 form a T-shaped integral prefabricated beam 2. The surface dimensions correspond to each other, and the width of the connecting portion corresponds to the width of the prefabricated corbel column 1 .

[0039] Further, there are eight high-strength bolts 3, four of which are distributed on the force-applying surfaces on both sides of the main body, and the high-strength bolts 3 are arranged in rows at equal intervals in the vertical direction.

[0040] Further, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com