Reclamation area ultra-deep concrete diaphragm wall structure and construction method thereof

A construction method and a technology for connecting walls to ground, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of high construction cost, long period, and difficult earthwork excavation, so as to avoid water leakage in the later stage and ensure socket connection. Width, the effect of increasing construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The inner diameter of the foundation pit of this project is 100m, and the depth of excavation is 50m. According to the geological survey report and design drawings, the ground connection wall structure penetrates into the rock, that is, the micro-weathering reaches 15m-30m, the maximum strength of the rock sample reaches 90Mpa, and the flowing water section is reasonably arranged. The total construction period of the bidding documents is 550d. Excluding the related construction of the foundation pit excavation process, the construction of the foundation pit enclosure structure can only take up to 220d. Therefore, very reasonable planning and construction deployment is required.

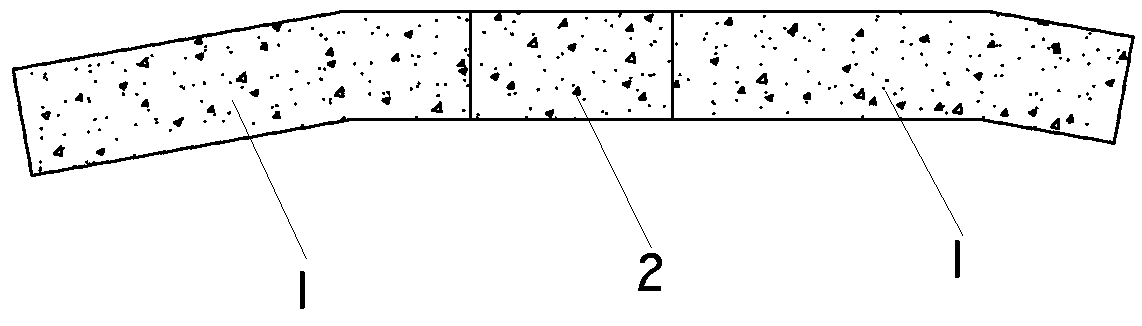

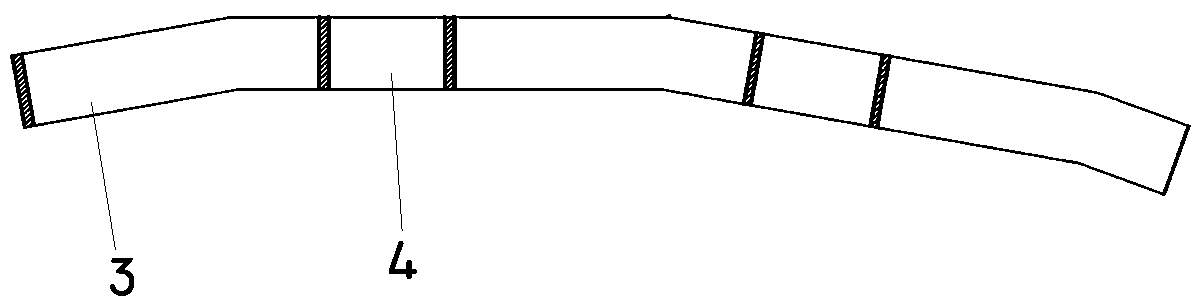

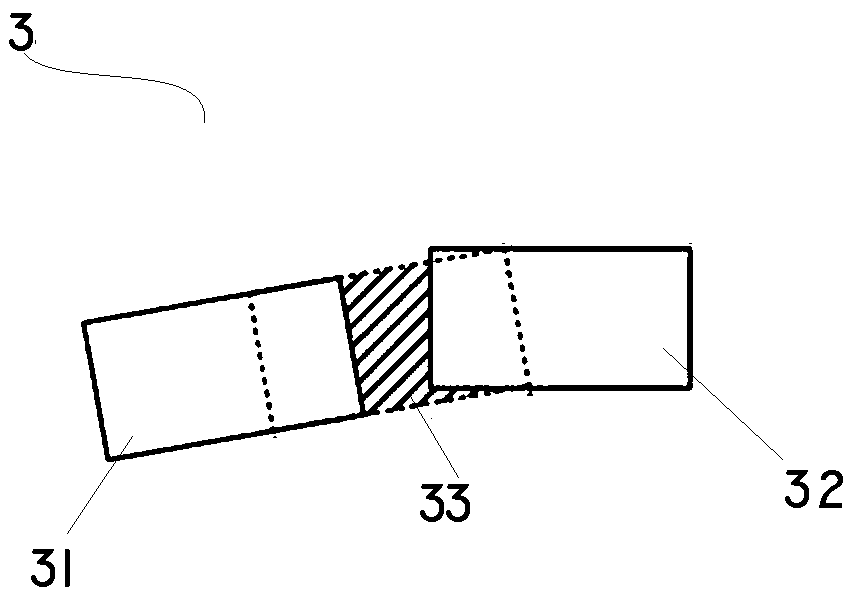

[0053] like figure 1 As shown, the present invention provides an ultra-deep ground connection wall structure in the reclamation area. The ground connection wall structure is annular, and the ground connection wall structure includes Type I ground connection walls 1 and Type II ground connection...

Embodiment 2

[0102] Embodiment 2, the ultra-deep ground connection wall structure and its construction method in the reclamation area, is the same as that of Embodiment 1, the difference is that the construction of the ground connection wall trenching relies on double-wheel milling machines. The specific number of machines can be: 6 sets of double-wheel milling machines. The working space of each double-wheel milling machine 6 needs to be 5*8m, and the backstage needs to be 20㎡. Efficiency in soil layer 8: the comprehensive construction efficiency of double-wheel milling 6 in soil layer 8 is 3.57m / hour; efficiency in rock layer 9: the comprehensive construction efficiency of double-wheel milling 6 is 0.01 m / hour. With the same engineering quantity as that of embodiment 1, the construction period exceeds 400 days.

Embodiment 3

[0103]Embodiment 3, the ultra-deep ground connection wall structure and its construction method in the reclamation area, is the same as that of Embodiment 1, the difference is that: first use a rotary excavator to guide the hole in the construction of the ground connection wall groove formation, and then use a double-wheel milling machine 6 to complete the construction. Groove, all the other processes are constructed with double-wheel milling 6. The specific number of machines can be: 6 sets of double-wheel milling machines, and 6 sets of rotary excavators. The working space of each double-wheel milling machine 6 needs to be 5*8m, the background needs 20㎡, and the working space of each rotary excavator is 4m*6m. Efficiency in soil layer 8: double-wheel milling 6 comprehensive construction efficiency of soil layer 8 is 3.57m / hour; efficiency in rock layer 9: double-wheel milling 6 comprehensive construction efficiency is 0.05 m / hour, rotary digging lead hole 7 efficiency is 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com