Closing construction method for steel bar-concrete superposed beam cable-stayed bridge

A technology of closing dragons and tools, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of high control precision requirements, low safety assurance coefficient, and difficulty in guaranteeing construction quality, and achieve lower control accuracy requirements and safety assurance coefficients. High efficiency and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

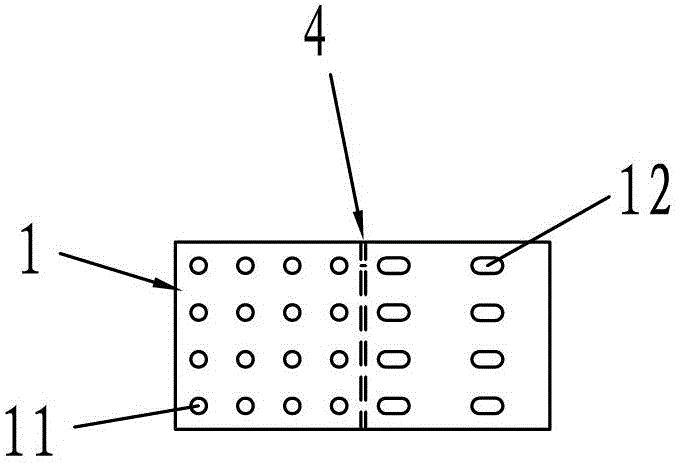

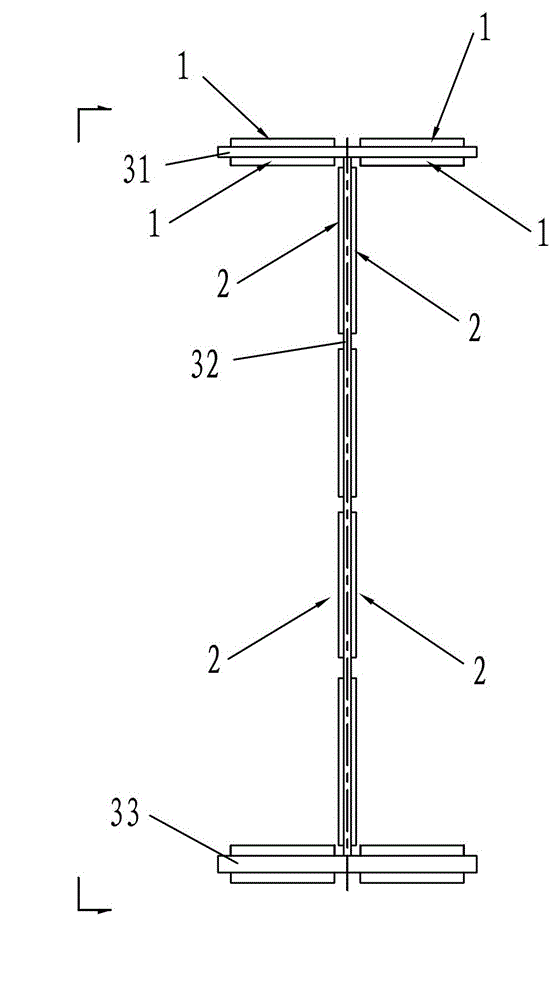

[0043] see figure 1 , the structure of tool splicing plate 1 of the present invention is as follows:

[0044] It is a rectangle, half of which is provided with circular holes 11, there are 4 rows, 4 in each row, and the other half is provided with 4 rows of oval holes 12, 2 in each row, wherein, the position and size of the circular holes and the bridge The drilling holes on the I-shaped main stringer 3 are consistent, but the quantity is less than the fixed holes on the I-shaped bridge stringer 3 (4 rows are arranged on the I-shaped bridge stringer 3, and each row is 7); Shaped holes 12 correspond to the spaced fixed holes on the I-shaped main longitudinal girders 3 of two rows of bridges, and the length direction of the oval holes 12 is from left to right (ie the longitudinal direction of the bridge).

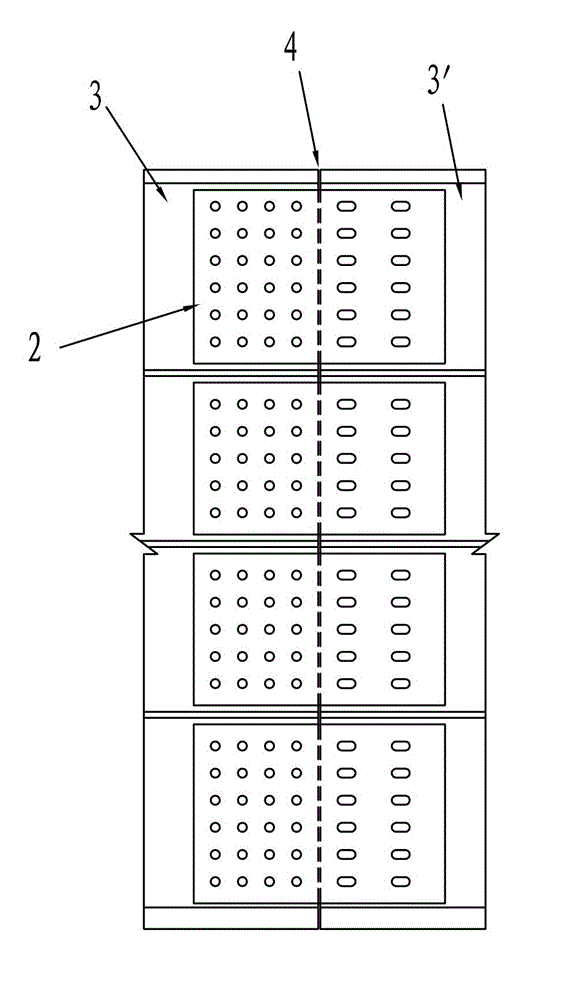

[0045] see image 3 , the tool splicing plate 2 of the present invention is similar to the tool splicing plate 1, but its row number is 7 rows. There are four circular hol...

Embodiment 2

[0048] The timing construction method of the steel-mixed composite girder cable-stayed bridge of the present invention mainly includes the following parts:

[0049] Construction process of the present invention is as follows:

[0050] (1) Use the corresponding measurement and test methods to continuously observe the attitude of the Helongkou two beam sections in advance.

[0051](2) According to the data obtained from continuous observation, the main longitudinal beam and the tool splicing plate of the closing section are blanked and manufactured in advance. Among them, the elliptical hole is provided with a bolting margin of 20-30mm, which is used for the temporary splicing of the closing beam section and the cut-end steel main beam when the mid-span closing is completed;

[0052] (3) Arrange corresponding weights at the Helongkou and adjust the posture of the Helongkou.

[0053] (4) The bridge deck crane is used for hoisting and assembling construction of the main longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com