Overhung composite insulator string and method for printing same by using 3D

A composite insulator, 3D printing technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of wasting time, reducing construction efficiency, unstable connection, etc., to simplify the process, reduce manpower and material resources, and economic benefits. and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

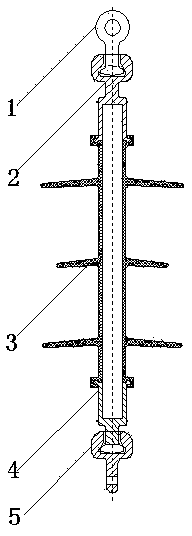

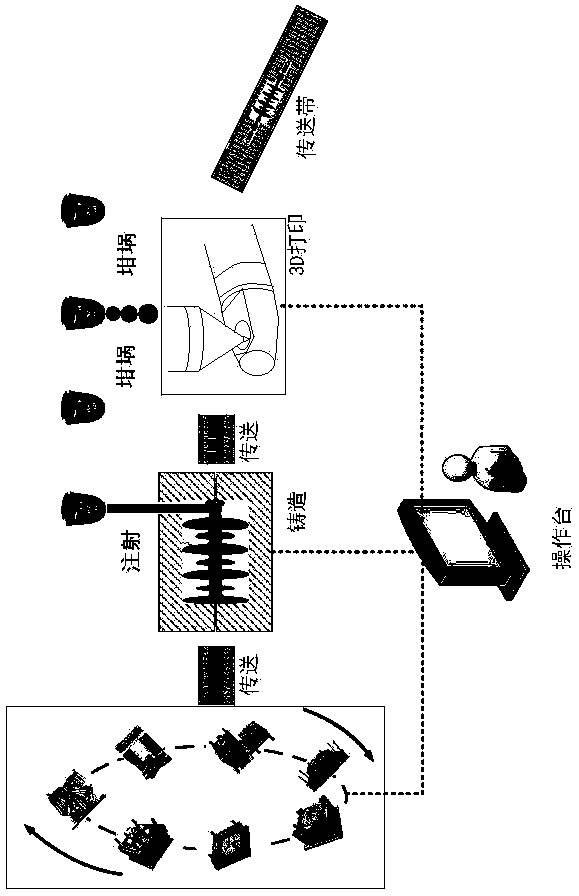

[0030] Step 1: Take out the insulator string, cast the insulator string into shape, preheat the surface of the power fittings, use a ray stress tester to analyze the residual stress of the microstructure of the cladding layer, and obtain the performance of the power fittings, Internal structure parameters, draw the three-dimensional model of the ball head, ball socket, bowl head hanging plate, and ball head hanging ring in the computer, and generate the three-dimensional CAD model of the ball head, ball socket, bowl head hanging plate and ball head hanging ring in the computer After the 3D model is generated, the files converted into STL format are respectively imported into the 3D droplet printer.

[0031]Step 2: Use the 3D droplet printer to make the 3D CAD model of the part, then slice and layer the model according to a certain thickness, convert the 3D information of the part into a series of 2D contour information, and set the 3D industrial computer on the side of the drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com