Assembly-free manufacturing method and device for micromechanical mechanism

A manufacturing method and technology of a manufacturing device, applied in the field of micro-machine manufacturing, can solve the problems of restricting designers' design ideas, difficult to implement parts assembly, and inability to design micro-machines, so as to shorten the research and development and production cycle, shorten the manufacturing time, and enhance the aesthetics. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

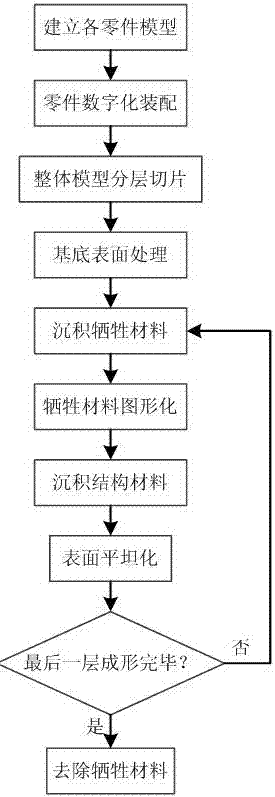

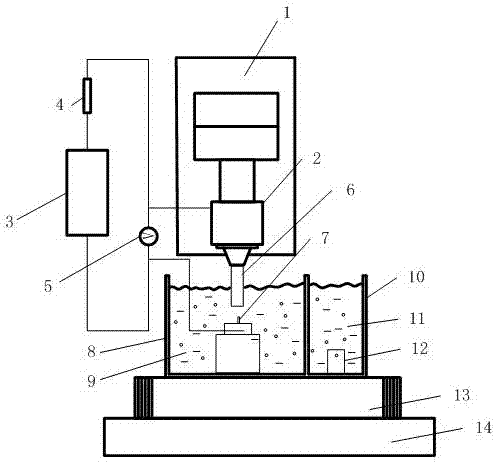

Method used

Image

Examples

Embodiment 1

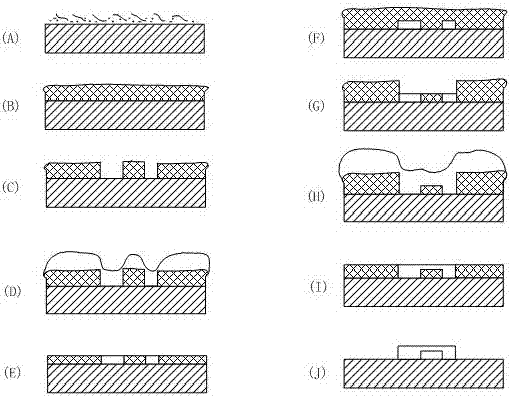

[0078] Figure 5 is the three-dimensional model of the hinge mechanism of Embodiment 1 of the present invention, Figure 6 It is the three-dimensional model after the first layer of the hinge mechanism of the embodiment of the present invention is formed, Figure 7 It is the three-dimensional model after the second layer of the hinge mechanism of the embodiment of the present invention is formed, Figure 8 It is the three-dimensional model after the third layer of the hinge mechanism of the embodiment of the present invention is formed. Such as Figure 5~Figure 8 The hinge mechanism shown is the manufacturing target, the material is copper, and the specific size is determined, and its manufacturing process according to the assembly-free manufacturing method of the micromechanical mechanism is as follows:

[0079] (a) In the host computer, establish a three-dimensional model of the outer arm 18 and inner arm 19 of the hinge mechanism, and digitally assemble the two to obtain...

Embodiment 2

[0106] Other features of this embodiment are the same as embodiment 1 except the following features:

[0107] The material of the hinge mechanism is nickel.

[0108] In the step (b2), a micro electric discharge milling numerical control program is generated through path planning.

[0109] In the step (c), take a copper block of appropriate size.

[0110] In the step (d), the deposited sacrificial material is copper, preferably, the main component of the electroplating solution may be copper sulfate, and suitable additives are added.

[0111] In the step (e), preferably, the working fluid can be electric spark oil, the cathode can be a tungsten electrode with a diameter of about 30 microns, the power supply can be a pulse power supply of about 70V, and the pulse width modulation is about 0.5 μm.

[0112] In the step (f), the deposited structural material is nickel, preferably, the main component of the electroplating solution may be nickel sulfamate, and appropriate additives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com