Plastic floor laying structure and construction method thereof

A technology of plastic floor and construction method, applied in the direction of building structure, building, floor, etc., to achieve the effect of reducing construction cost, avoiding delamination and bulging, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

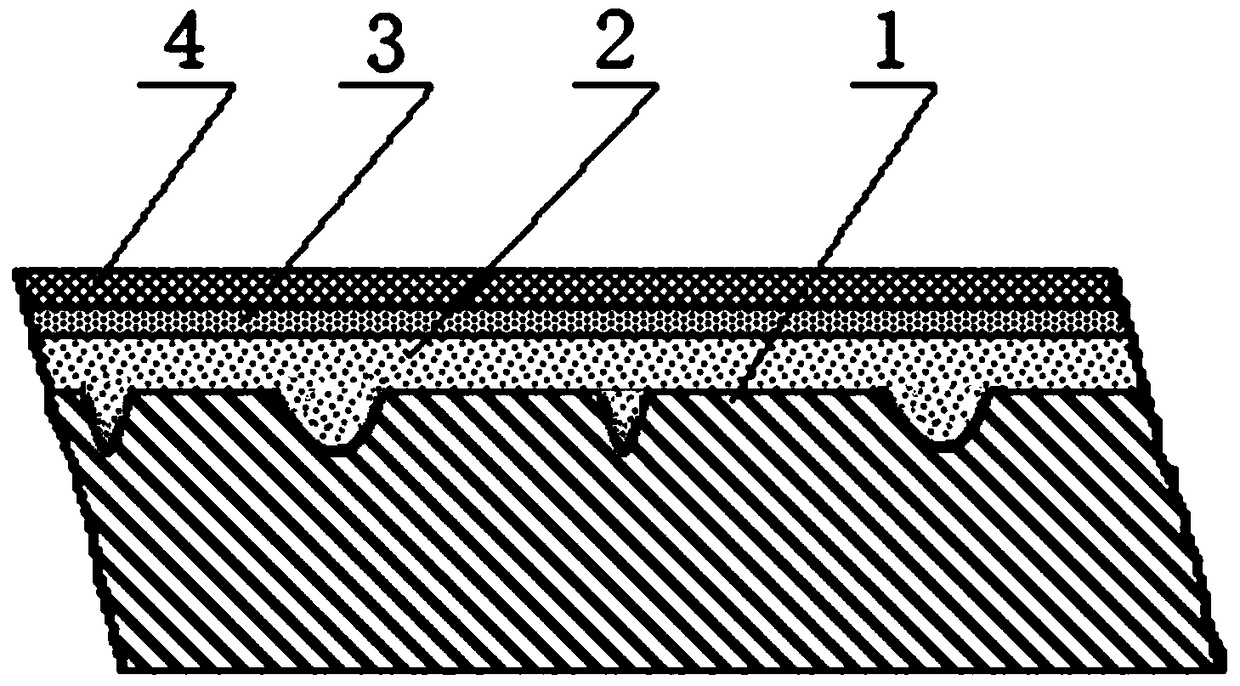

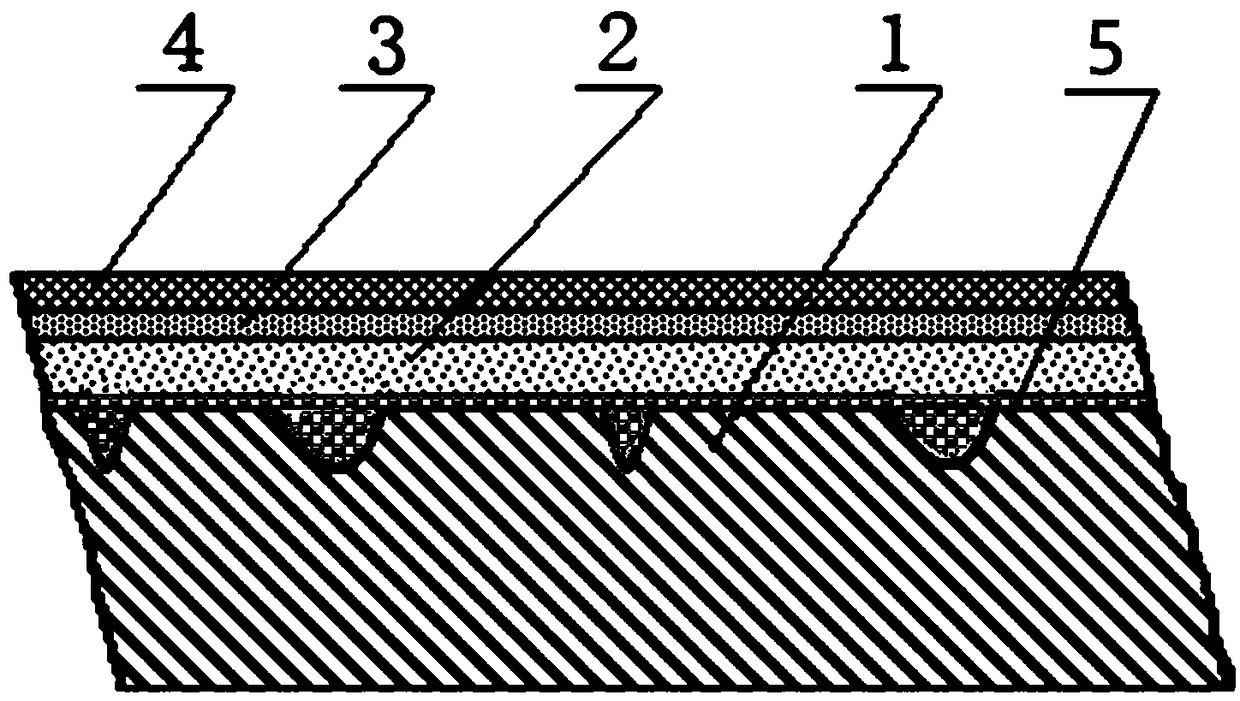

[0044] A plastic floor laying structure, such as figure 1 As shown, the rough pockmarked surface layer 1, the self-leveling layer 2, the adhesive layer 3, and the plastic floor layer 4 are arranged in sequence from bottom to top; the rough pockmarked surface layer 1 is formed by rough grinding on the surface of the original ground structure. The floor structure is generally ceramic tiles.

[0045] The ground structure involved in the present invention is generally a decorated indoor ground structure of a rough house. Of course, the present invention is also applicable to the ground structure of a rough house without decoration.

[0046]In the transformation of some old decoration projects, it is usually necessary to remove the original ground structure, such as ceramic tiles, and then level the ground with cement mortar before laying the plastic floor. This process will consume a lot of labor and cost. , and will produce a large amount of construction waste. After cleaning th...

Embodiment 2

[0048] The scheme of embodiment 2 is basically the same as that of embodiment 1, the only difference is that the thickness of the self-leveling layer 2 is 2 mm, the thickness of the plastic floor layer 4 is 1.5 mm, and the raw material of the self-leveling layer is wear-resistant self-leveling cement mortar.

[0049] The thickness of the self-leveling layer is controlled within a certain range, which can not only play the role of leveling the ground, but also well avoid the phenomenon of cracking or drumming in the later self-leveling layer, which will seriously affect the laying effect of the plastic floor.

[0050] Ordinary cement mortar is not used here to level the ground. The main considerations are that the construction of ordinary cement mortar is complicated, the flatness is difficult to control, the ground hardness of ordinary cement mortar is poor, the wear resistance is poor, it is easy to dust, and the required maintenance period is long. and other issues; the advan...

Embodiment 3

[0053] The solution of embodiment 3 is basically the same as that of embodiment 2, the only difference is that the thickness of the self-leveling layer 2 is 3 mm, and the thickness of the plastic floor layer 4 is 4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com