Formwork supporting device for wall corner portion construction and construction method

A technology of formwork support and construction method, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork components, and preparation of building components on site, which can solve the problems of long-term erection and dismantling, various construction procedures, Improve construction costs and other issues to achieve the effect of improving construction efficiency, improving construction progress, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

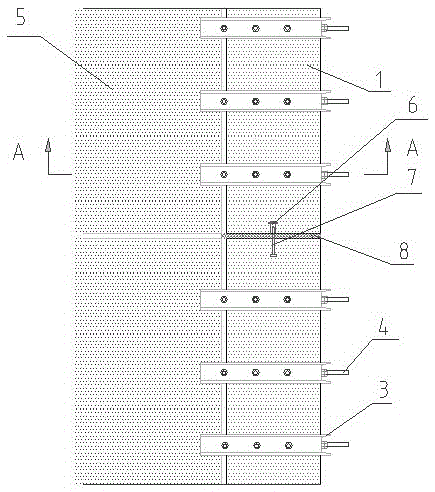

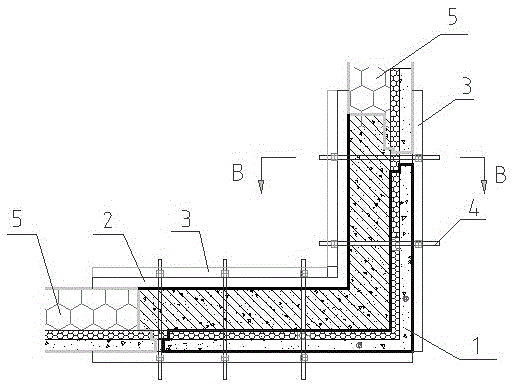

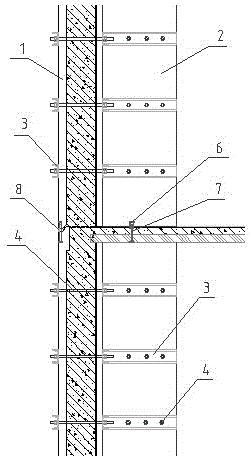

[0052] This embodiment is used in the occasion of building a supporting device when using the PCF board as the outer formwork of the corner cast-in-place concrete vertical member.

[0053] A formwork supporting device used for the construction of the corner of the wall, such as figure 1 , figure 2 and image 3 As shown, it includes an outer formwork and an inner formwork, and also includes a fixing device for clamping the outer formwork and the inner formwork. The fixing device includes section steel and tie rods. Corresponding to the outer template and the section steel, there are installation holes suitable for the size of the tie rods, and the outer template is a PCF board 1 . In this embodiment, the inner formwork is made of aluminum alloy, the inner formwork uses an aluminum alloy formwork 2 , the section steel is a channel steel 3 , and the tie rods are wall-through bolts 4 .

[0054] The channel steel 3 extends to the installed prefabricated exterior wall panel 5, a...

Embodiment 2

[0070] This embodiment is used in the occasion of building a supporting device when using the PCF board as the outer formwork of the corner cast-in-place concrete vertical member.

[0071] A formwork supporting device used for the construction of the corner of the wall, such as Figure 5 , Figure 6 and Figure 7 As shown, it includes an outer formwork and an inner formwork, and also includes a fixing device for clamping the outer formwork and the inner formwork. The fixing device includes section steel and tie rods. Corresponding to the outer template and the section steel, there are installation holes suitable for the size of the tie rods, and the outer template is a PCF board 1 . In this embodiment, an aluminum alloy formwork 2 is used as the inner formwork, the section steel is an angle steel 9 , and the pull rod is a fully threaded screw 10 .

[0072] The angle steel 9 extends to the installed prefabricated exterior wall panel 5, and corresponding installation holes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com