Shield tunnel karst cave filling method

A technology for shield tunnels and karst caves, which is applied in the direction of filling, earthwork drilling, safety devices, etc., to achieve the effects of saving resources, speeding up construction progress, and promoting waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

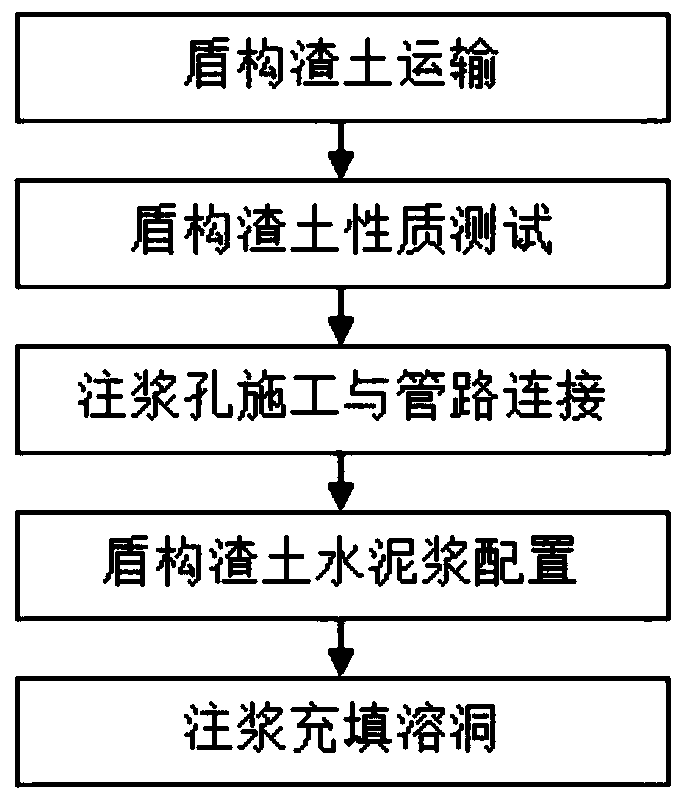

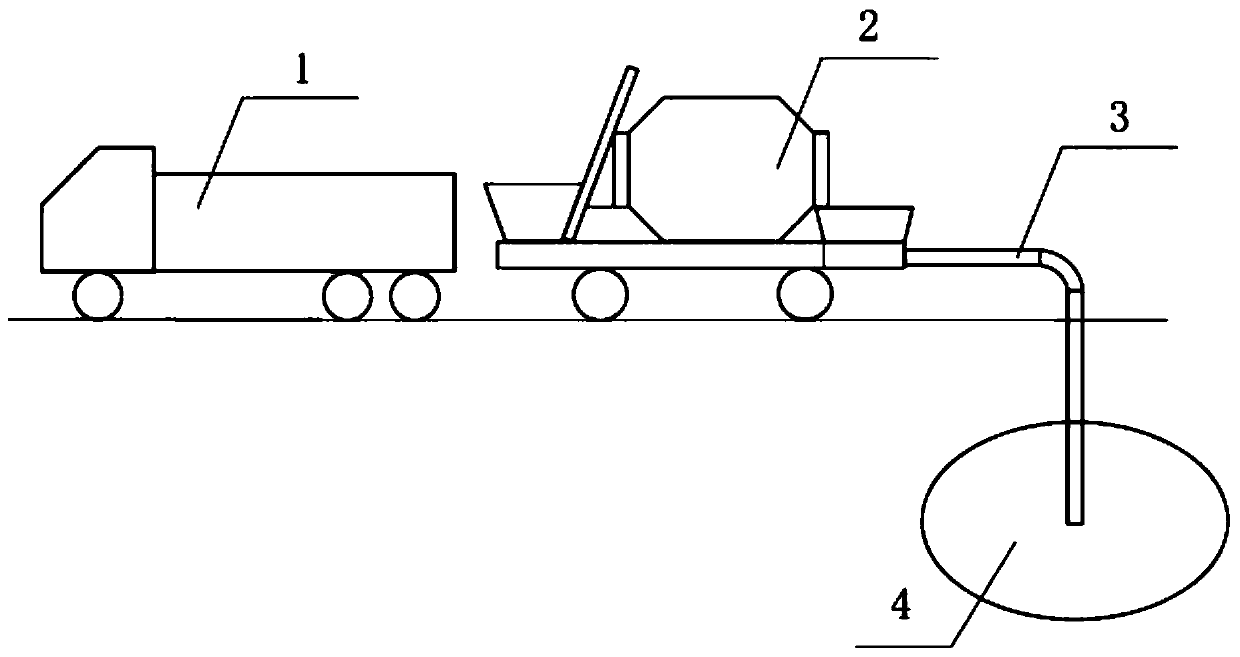

[0027] like Figure 1-2 As shown, the present embodiment provides a shield tunnel filling method, comprising the following steps:

[0028] (1) Shield muck transportation:

[0029] Before the karst cave filling construction, transport the shield slag from the muck storage pool in the subway tunnel construction section that has already started to the karst cave filling construction site, and select the shield slag from the sandy pebble layer without dehydration and drying; Soil transport vehicle 1 uses a muck truck or a mixer truck to transport the shield muck to the cave filling construction site;

[0030] (2) Test of shield muck properties:

[0031] After the shield muck was transported to the treatment construction site of Karst Cave 4, samples were collected for experiments to test the properties of the shield muck: the moisture content of the muck was determined by the drying method, and the particle gradation of the muck was determined by the sieving method. Determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com