Steel thin-wall sounding pipe automatic welding device for bored concrete pile

An automatic welding and cast-in-place pile technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high physical fitness requirements of workers, low efficiency of manual welding, and reduced overall construction efficiency, saving resources and reducing energy consumption. Work burden, avoid the effect of manual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

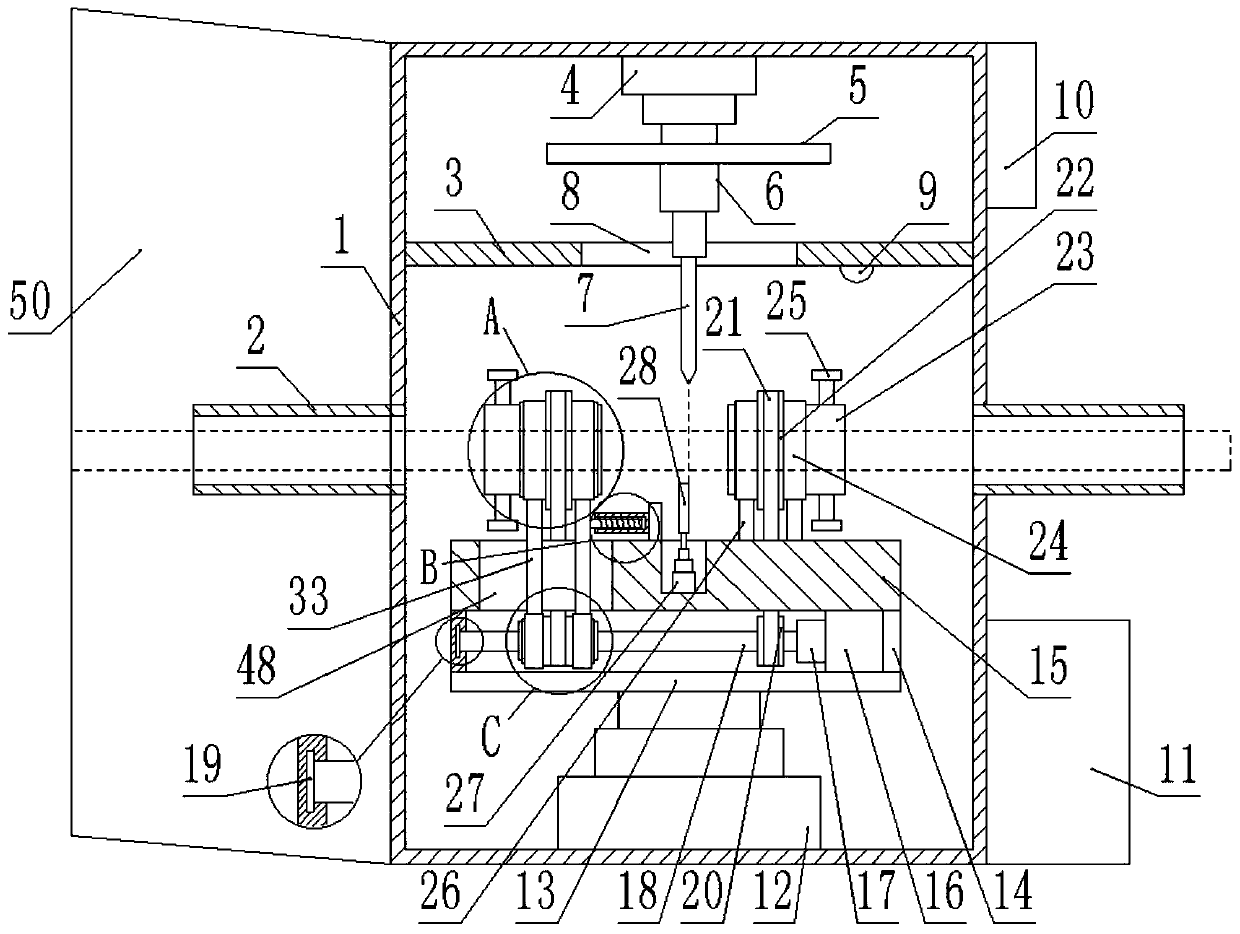

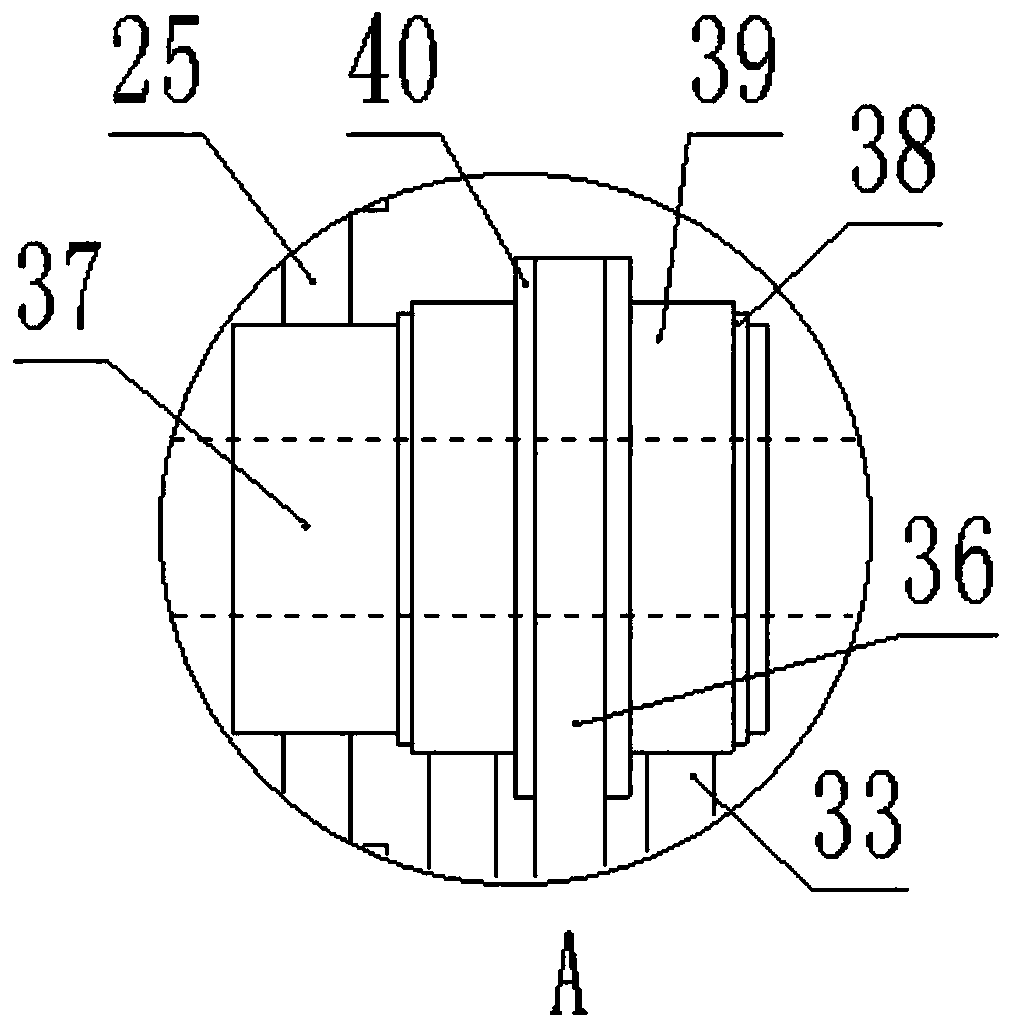

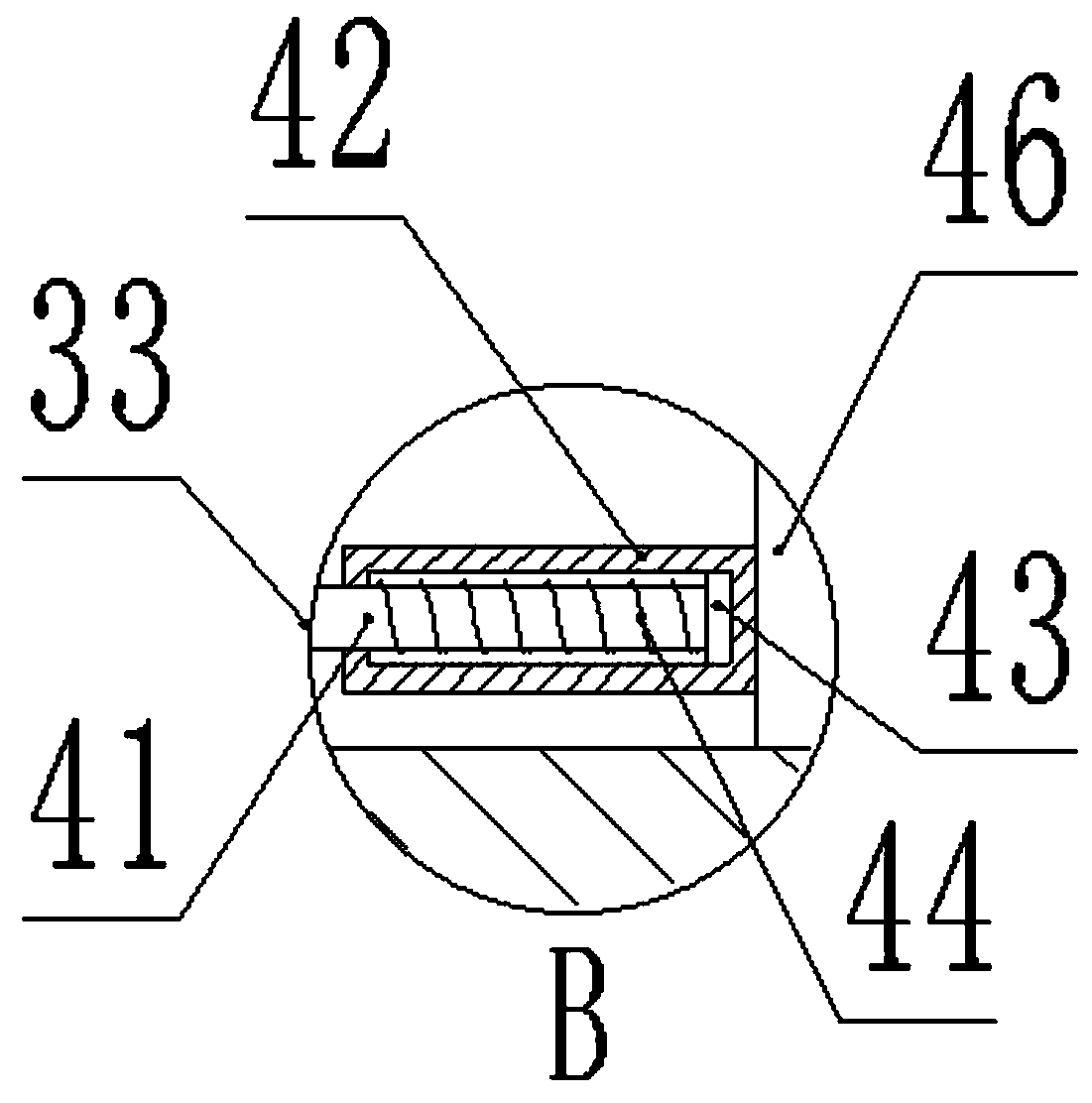

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9As shown, a steel thin-walled acoustic tube automatic welding device for concrete pouring piles includes a box body 1, and feeding barrels 2 are symmetrically fixed on both sides of the box body 1, and the axes of the two feeding barrels 2 are arranged opposite to each other. The first hydraulic lifting device 4 is fixedly installed on the inner top surface of the box body 1, and the piston rod at the bottom end of the first hydraulic lifting device 4 is fixedly installed with a baffle plate 5, and the bottom end of the baffle plate 5 is fixedly installed with an automatic A telescopic rod 6, a partition 3 is installed on the top of the box body 1, an opening 8 is fixed at the center of the partition 3, the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com