Mixing and pile-pressing integrated machine

An all-in-one machine and mixer technology, applied in the field of hydraulic pile machines, can solve the problems of many construction workers, low construction efficiency, and poor pile quality, and achieve the effect of simple construction procedures, high construction efficiency, and good pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

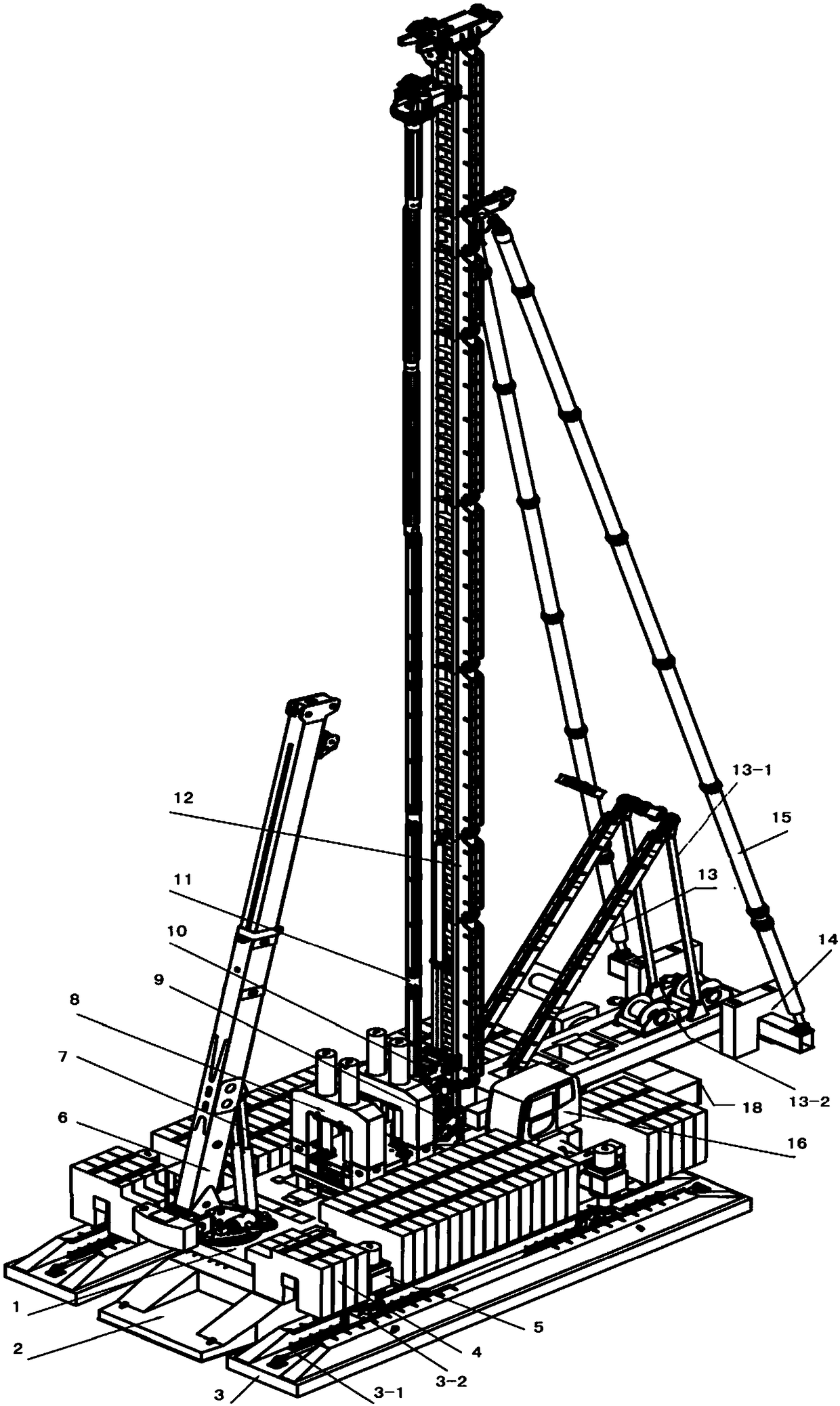

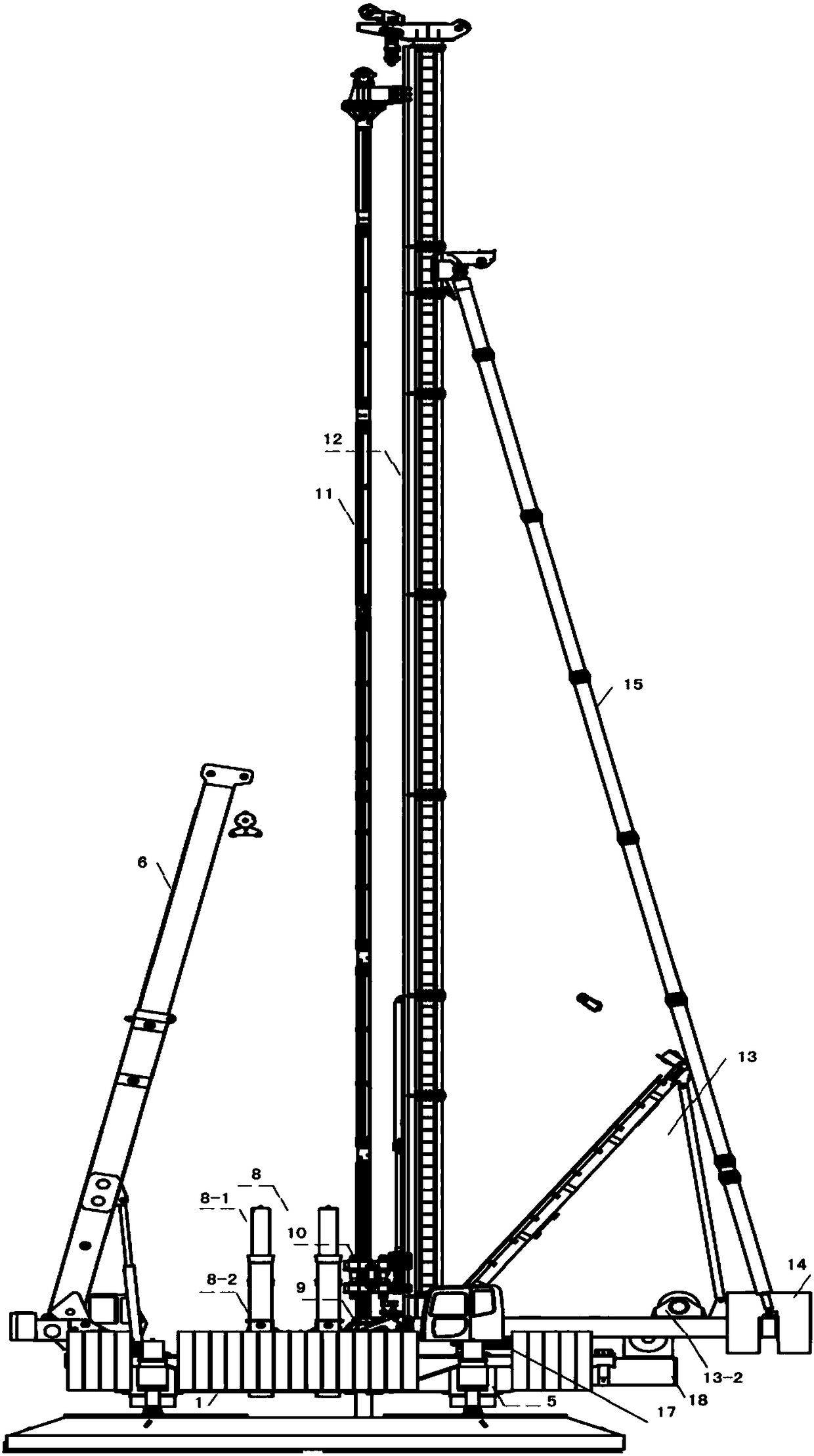

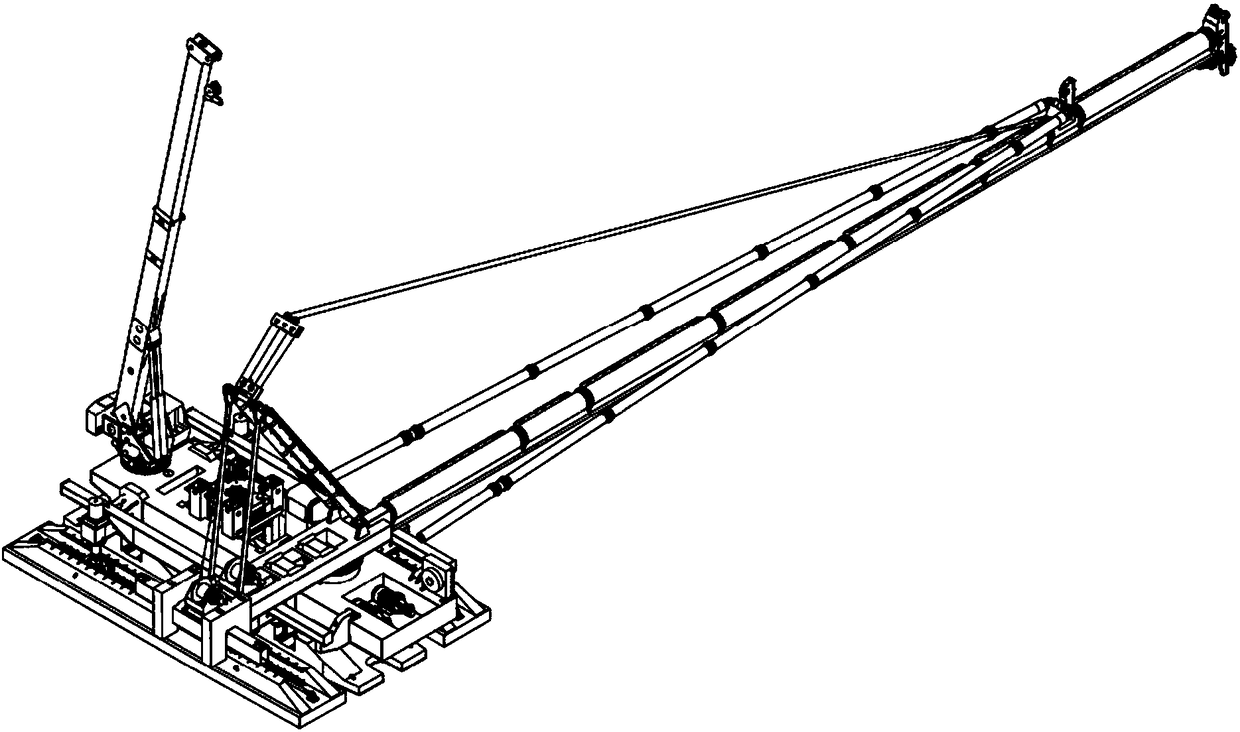

[0020] refer to Figure 1-Figure 2 , the present embodiment includes two short boats 2, two long boats 3, agitating pile drilling mechanism and hydraulic pile pressing mechanism, and the stirring pile drilling mechanism and hydraulic pile pressing mechanism are sequentially connected on two short boats 2 and two long boats 3 to form an integrated body Type pile machine structure; the mixing drilling mechanism is connected with the hydraulic pile pressing mechanism through the slewing bearing to form a rotatable connection structure, so that the mixing drilling mechanism can rotate 0-360 degrees relative to the hydraulic pile pressing mechanism; Frame device 13, to drive the stirring and drilling mechanism to lift or fall; the stirring and drilling mechanism and the hydraulic pressure pile mechanism are connected to the long ship 3 through the legs 5 and connected to the short ship 2 through the pin shaft; There is a long boat oil cylinder 3-1 and a wheel group 3-2 in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com