Ballast track laser intelligent track lifting and lining system and construction method

A construction method and technology for pulling up the road, which are applied in the directions of track, track laying, track maintenance, etc., can solve problems such as the inability to eliminate long-wave irregularities, achieve controllable construction quality, ensure construction quality, and reduce construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

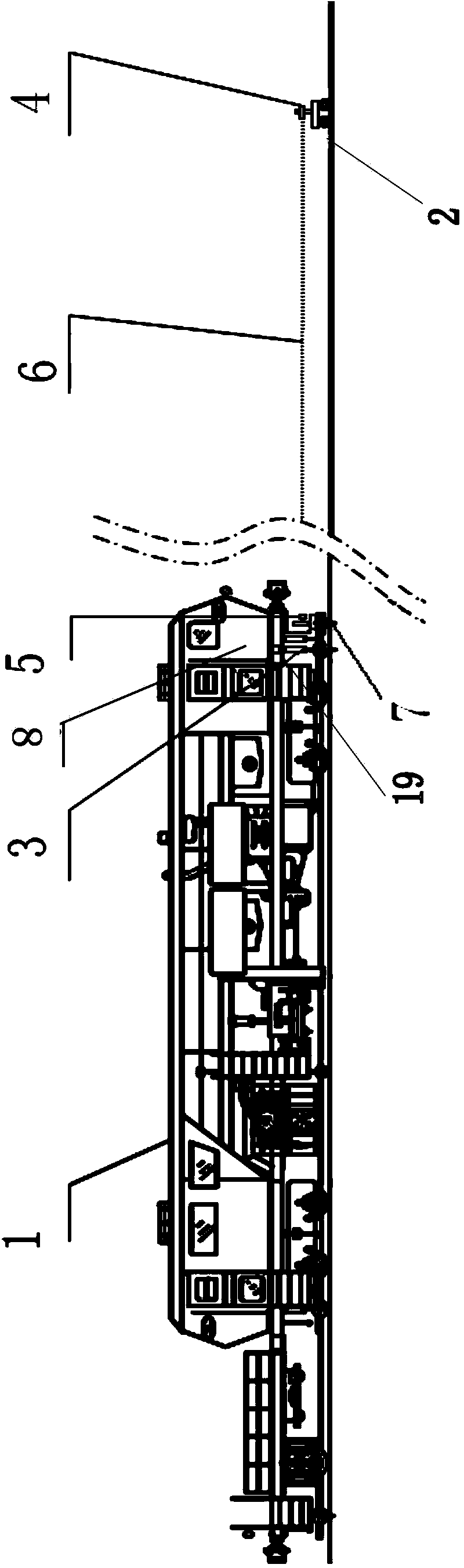

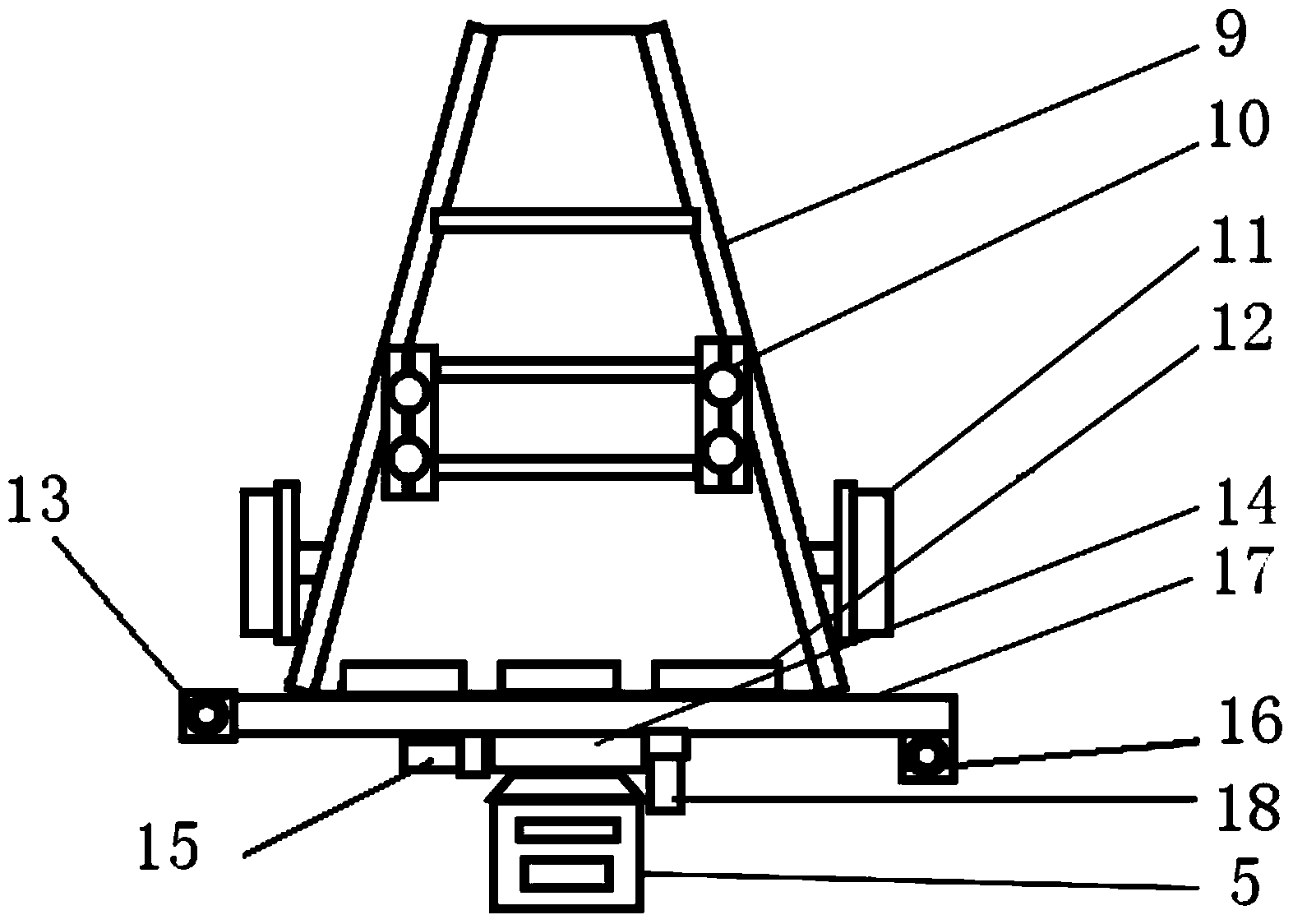

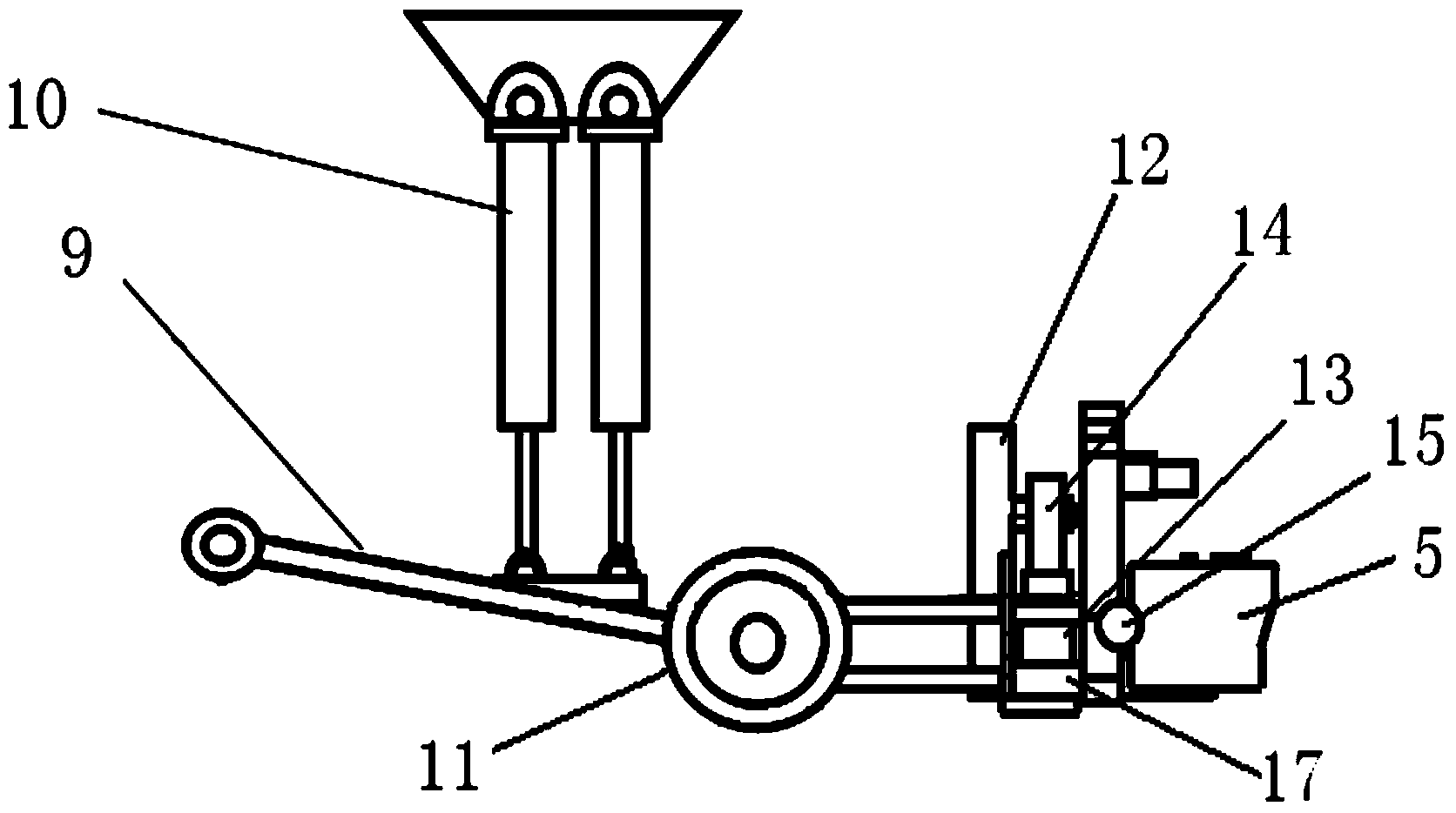

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown in the present invention is the ballasted track laser intelligent ballast track system,

[0048] Comprising a pull-up track tamping machine 1, an integrated full-line measuring device; the full-line measuring device includes a laser emitting device 4 and an image receiving device 5; The front-end image receiving car 7; the laser emitting device 4 is set on the laser emitting mobile car 2 at a set distance. Described image receiving device 5 is provided with two-dimensional automatic tracking mechanism; Comprising image receiver longitudinally moving oil pump 13, image receiver longitudinally moving track 14 and image receiver longitudinal tracking motor 15, and image receiver laterally moving oil pump 16, image receiving traversing track 17 and image receiver traversing tracking motor 18.

[0049] The image receiver moves the oil pump 13 vertically, which is responsible for the image receiver to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com