Manufacture method of high-strength TPU (thermoplastic polyurethane) compound fabric

A composite fabric and manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, lamination and other directions, can solve the problems of uneven film, low output and high cost of TPU composite fabrics, and achieve low cost and fabrics. The effect of uniform distribution and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

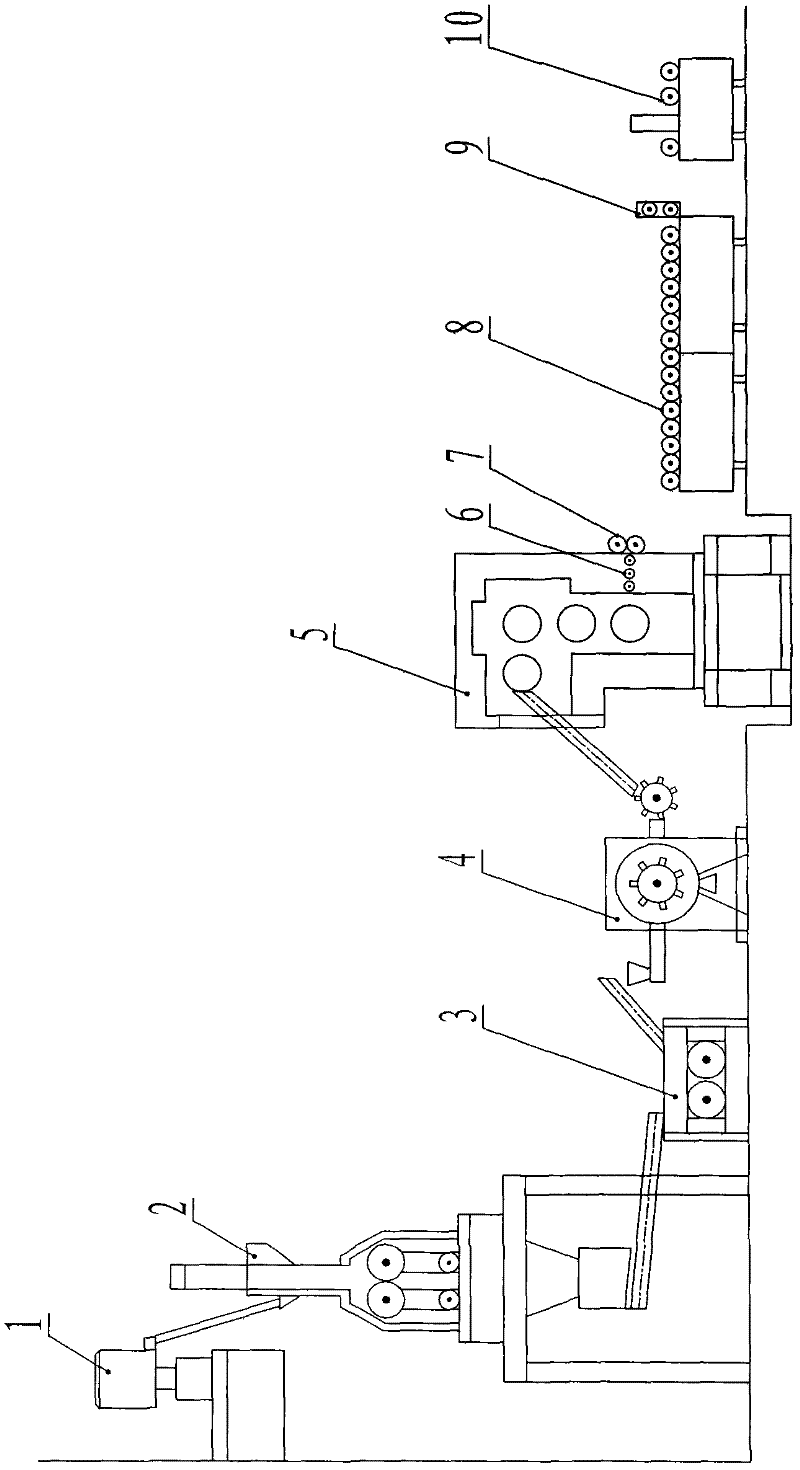

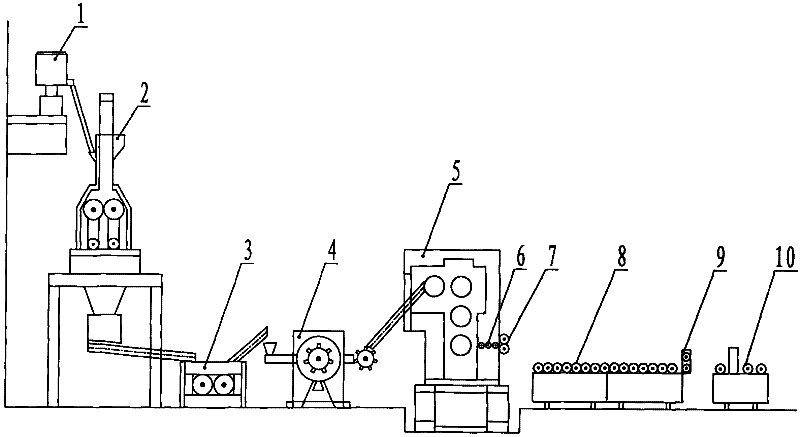

[0016] like figure 1 Shown, the manufacture method of high-strength TPU composite fabric of the present invention may further comprise the steps:

[0017] (1) Manufacture of TPU film, which specifically includes: ① Sending TPU material particles into high-speed mixer 1 for drying and drying, the temperature is controlled at 80°C to 130°C, and the time is controlled at 3 to 5 hours; ②The dried The TPU material particles are sent to the internal mixer 2 for mixing for 10-15 minutes, and the temperature is controlled at 100°C to 120°C; ③The mixture in the molten state is sent to the plastic mixer 3 through the conveyor belt to heat and plasticize, and the temperature is controlled at 140℃~180℃; ④ Send the plasticized raw materials to the screw filter 4 to filter impurities through the conveyor belt, the temperature is controlled at 140℃~180℃, and the filter mesh is 120 mesh to 200 mesh; ⑤ Fully plasticize the filter The final raw material is sent to the calender 5 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com