Graphene heat radiation paint, preparation method and applications

A technology of heat-dissipating coatings and graphene, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of heat conduction and heat dissipation, and achieve the effects of light weight, excellent heat conduction and heat dissipation effects, and high coating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Correspondingly, the embodiment of the present invention also provides a kind of preparation method of graphene heat dissipation coating, it comprises following preparation steps:

[0046] S01, take each component according to above-mentioned graphene heat-dissipating paint formula;

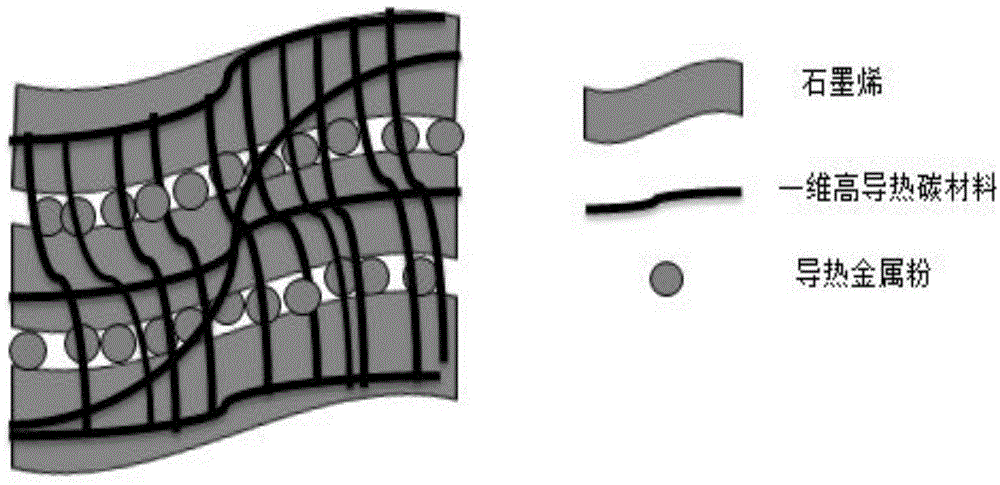

[0047] S02, mixing and stirring the polymer resin, graphene, one-dimensional carbon nanomaterial, inert solvent and dispersant to obtain a mixed material, and then grinding and dispersing the mixed material to prepare a graphene heat dissipation slurry;

[0048] S03. Add the heat-conducting metal powder, defoamer and inert solvent into the graphene heat-dissipating slurry, and mix uniformly to prepare the graphene heat-dissipating coating.

[0049] Specifically, in the above step S01, the components or preferred components are selected according to the above coating formulation, weighed separately, and ready for use.

[0050]In the above step S02, a stirrer can be selected (the control sp...

Embodiment 1

[0058] In parts by weight, 40 parts of saturated polyester resin (New Pace saturated polyester resin 173), 30 parts of bisphenol A type epoxy resin (E-20, Nanya brand 901 epoxy resin), 30 parts of melamine formaldehyde resin (methyl ether Amino resin 5717) 10 parts, graphene 15 parts, carbon nanofiber (Showa Denko VGCF) 8 parts, thermal conductive metal powder (silver-coated copper powder, spherical ≤10μm) 8 parts, dispersant (polyurethane AFCONA-4010) 4 parts, 2 parts of defoamer (organic silicon AFCONA-2501), 50 parts of propylene glycol methyl ether acetate, 50 parts of butyl acetate.

[0059] (1) Get 15 parts of graphene, dry (100 DEG C bake 2h) in vacuum drying box and remove moisture;

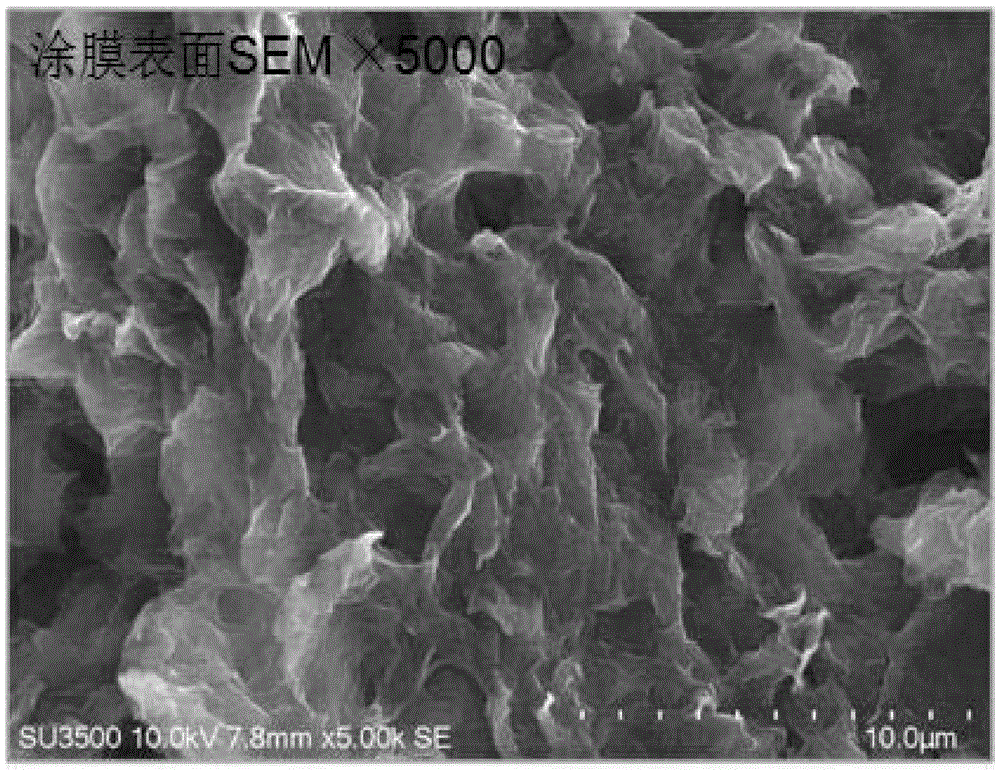

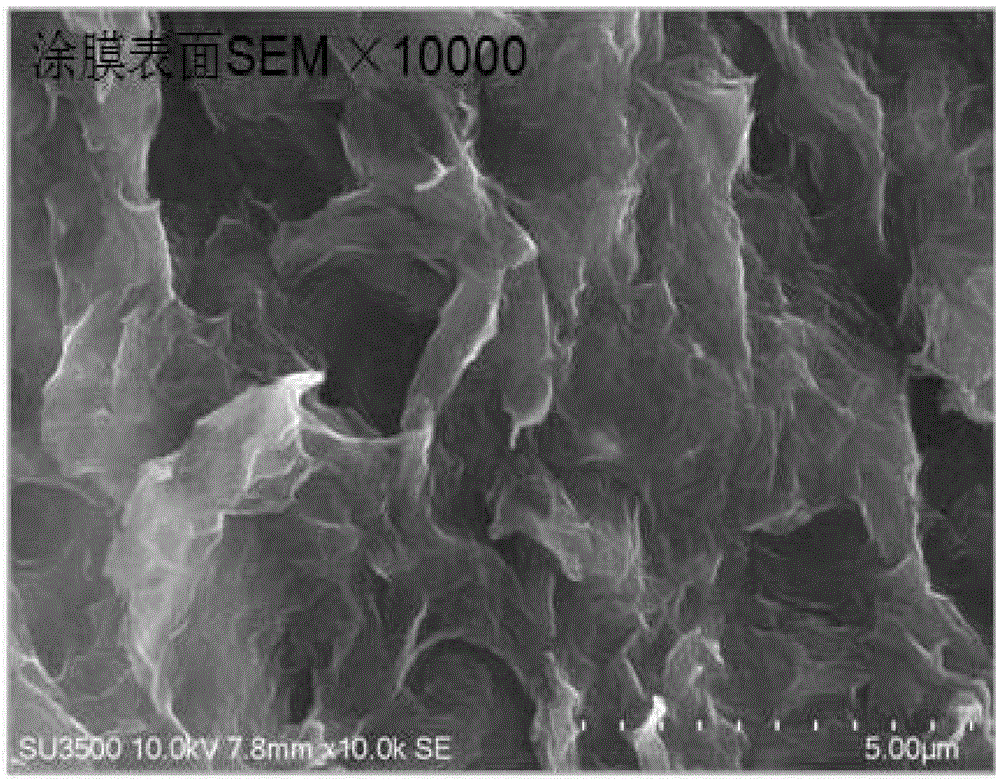

[0060] (2) 40 parts of saturated polyester resin, 30 parts of bisphenol A type epoxy resin, 10 parts of melamine formaldehyde resin, 15 parts of graphene, 8 parts of carbon nanofiber, 4 parts of dispersant, 50 parts of propylene glycol methyl ether acetate Mix and add to the mixer, contr...

Embodiment 2

[0064] In parts by weight, 40 parts of thermosetting acrylic resin (thermosetting acrylic resin 7205, Changxing resin), 30 parts of bisphenol A epoxy resin (E-20, Nanya brand 901 epoxy resin), melamine formaldehyde resin (isobutyl Etherified amino resin 138) 10 parts, graphene 15 parts, carbon nanofiber (Showa Denko VGCF) 8 parts, thermal conductive metal powder 8 parts (silver-coated copper powder, spherical ≤ 10 μm), dispersant (polyurethane AFCONA-4010) 4 parts, 2 parts of defoamer (AFCONA-2501), 50 parts of propylene glycol methyl ether acetate, 50 parts of butyl acetate.

[0065] (1) Get 15 parts of graphene, dry (100 DEG C bake 2h) in vacuum drying box and remove moisture;

[0066] (2) Mix 40 parts of thermosetting acrylic resin, 30 parts of bisphenol A epoxy resin, 10 parts of melamine formaldehyde resin, 15 parts of graphene, 8 parts of carbon nanofiber, 8 parts of dispersant, and 50 parts of propylene glycol methyl ether acetate Add in a mixer, control the speed at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com