Patents

Literature

33results about How to "Improve longitudinal thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene heat radiation paint, preparation method and applications

ActiveCN105273540ALight in massHigh film strengthEpoxy resin coatingsPolyester coatingsSolventRadiation

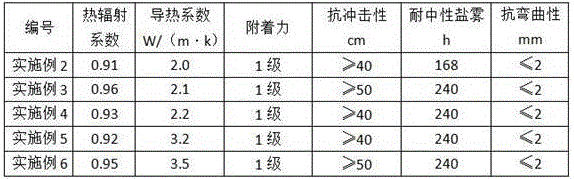

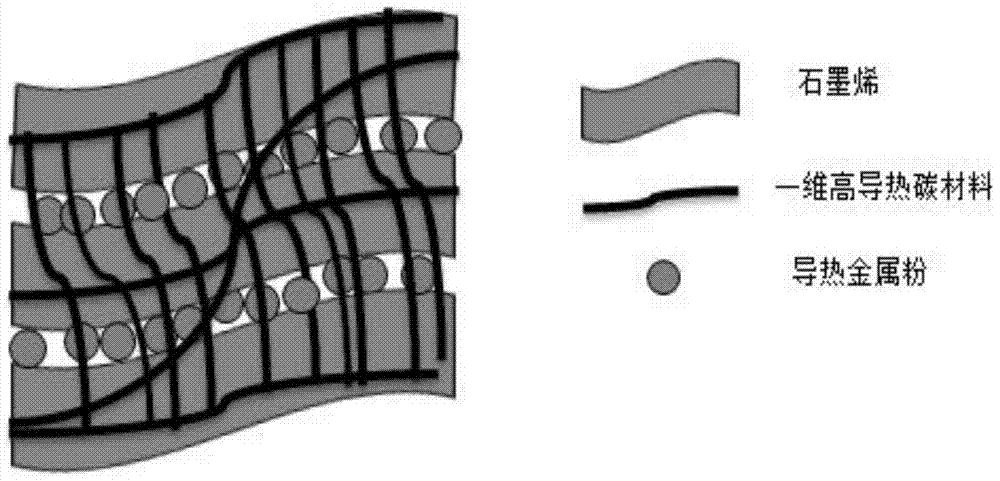

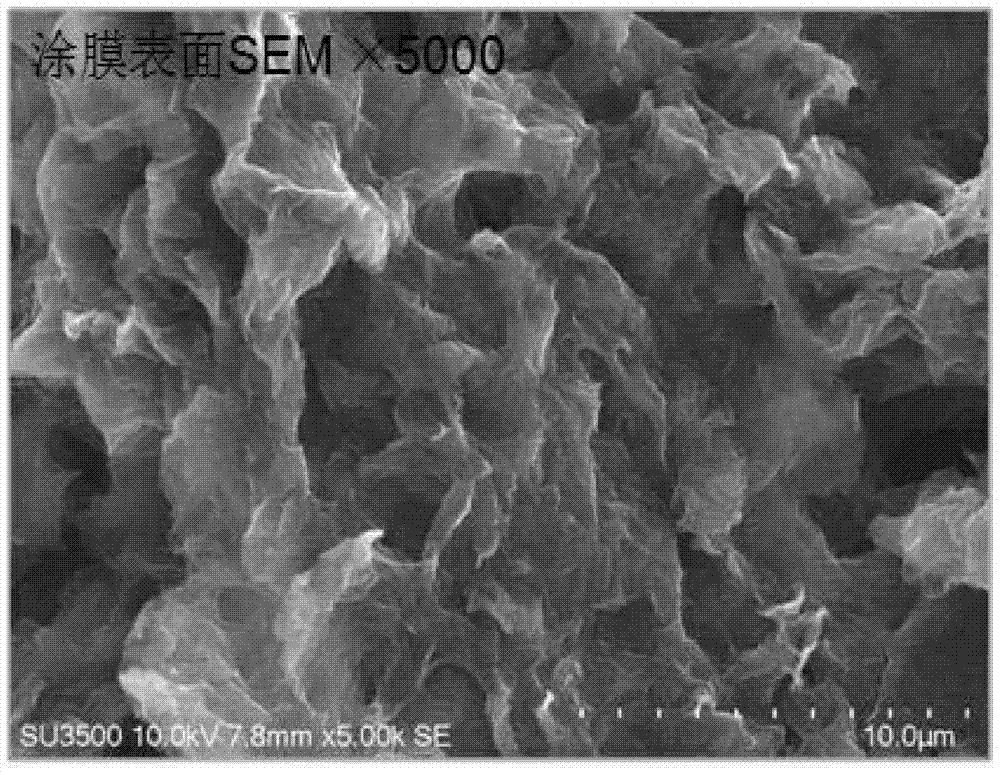

The invention discloses graphene heat radiation paint. The graphene heat radiation paint comprises the following ingredients, by weight, 40-80 parts of high-molecular resin, 5-15 parts of graphene, 1-8 parts of one-dimensional nanomaterials, 1-8 parts of heat conduction metal powder, 0.5-5 parts of dispersing agents, 0.5-5 parts of antifoaming agents and 100-200 parts of inert solvent. The heat conduction metal powder is at least one selected from silver powder, copper powder and aluminum powder and the granularity is 1-20 micrometers. The above paint has good heat radiation and heat conduction functions. The invention also discloses a preparation method for the graphene heat radiation paint. The preparation method mainly comprises processes of stirring, grinding and reblending. Operation is simple, and the cost is low. The graphene heat radiation paint is mainly applied in heat radiation of daily electronic products and also can be applied in spaceflight electronic devices with high requirements because of good heat conduction and heat radiation functions.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Graphene radiating material and preparation method thereof

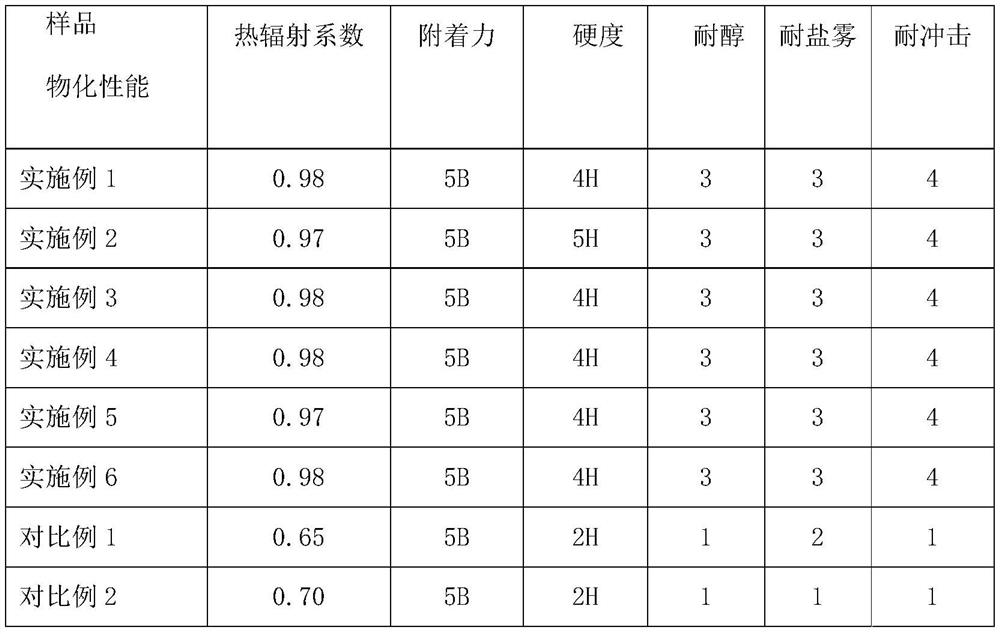

InactiveCN106221396AImprove cooling effectImprove adhesionAntifouling/underwater paintsPaints with biocidesSolventGraphene

The invention discloses graphene radiating material and a preparation method thereof. The graphene radiating material comprises agent A and agent B mixed well at a mass ratio of 1:1, the agent A comprises the following components, by weight: 40-60% of fluorocarbon resin, 30-50% of a mixed solvent, 5-15% of graphene, 0.5-1.5% of a leveling agent, and a 0.5-1.5% of a dispersant; the agent B comprises a mixed solvent and a curing agent at a mass ratio of 10:1. The prepared coating has the advantages such as high thermal conductivity coefficient, high thermal radiation coefficient, god radiating effect, acid and alkali tolerance, salt spray tolerance, impact resistance and high matrix adhesion, and the radiating material is widely applicable and usable.

Owner:DEYANG CARBONENE TECH

Graphene based heat-conducting interface material and preparation method thereof

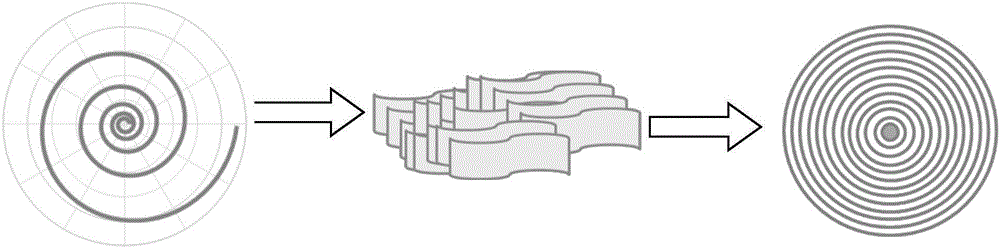

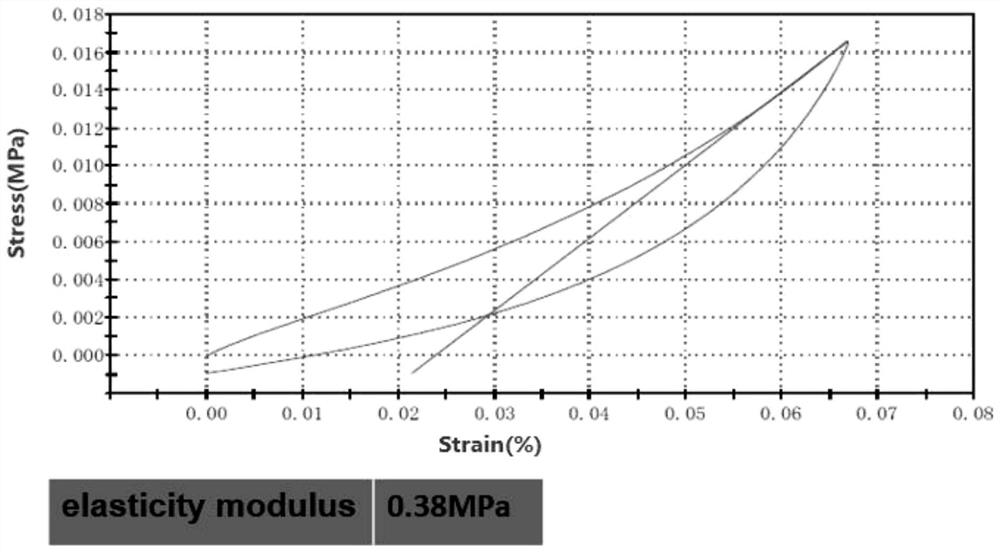

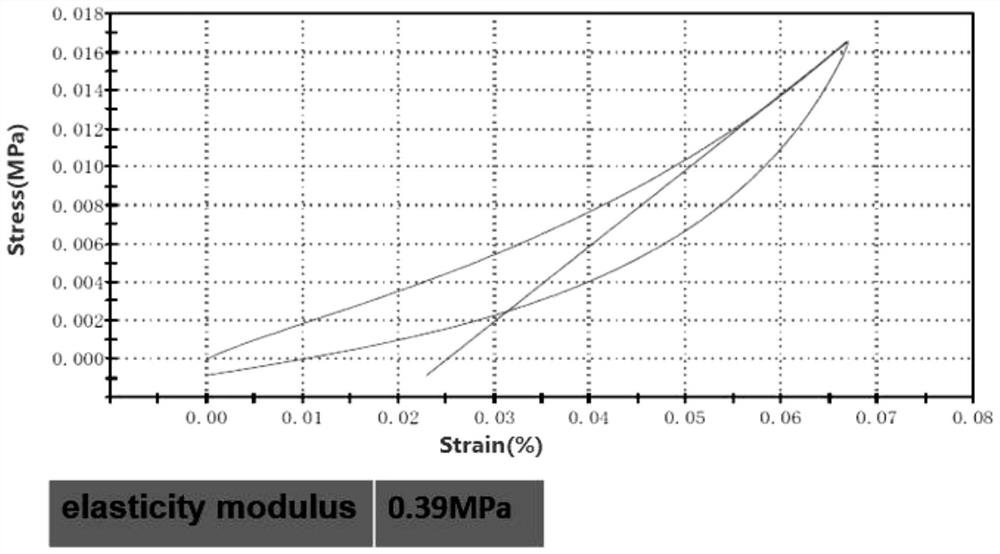

ActiveCN106633916AImprove longitudinal thermal conductivityFacilitate rapid heat dissipationHeat-exchange elementsCvd grapheneSilane coupling

The invention provides a preparation method for a graphene based heat-conducting interface material. The preparation method comprises the following steps: A) mixing a graphene material, vinyl silicone rubber, hexagonal boron nitride, flake graphite, hydroxy-terminated silicone oil, vinyl silicone oil and a first silane coupling agent, and carrying out stirring so as to obtain a rubber material, wherein the graphene material is one or more selected from the group consisting of graphene, graphene / silica composite powder and a graphene / silica composite sheet material; and B) subjecting the rubber material to pull-pressing, rolling and cutting so as to obtain the graphene based heat-conducting interface material.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

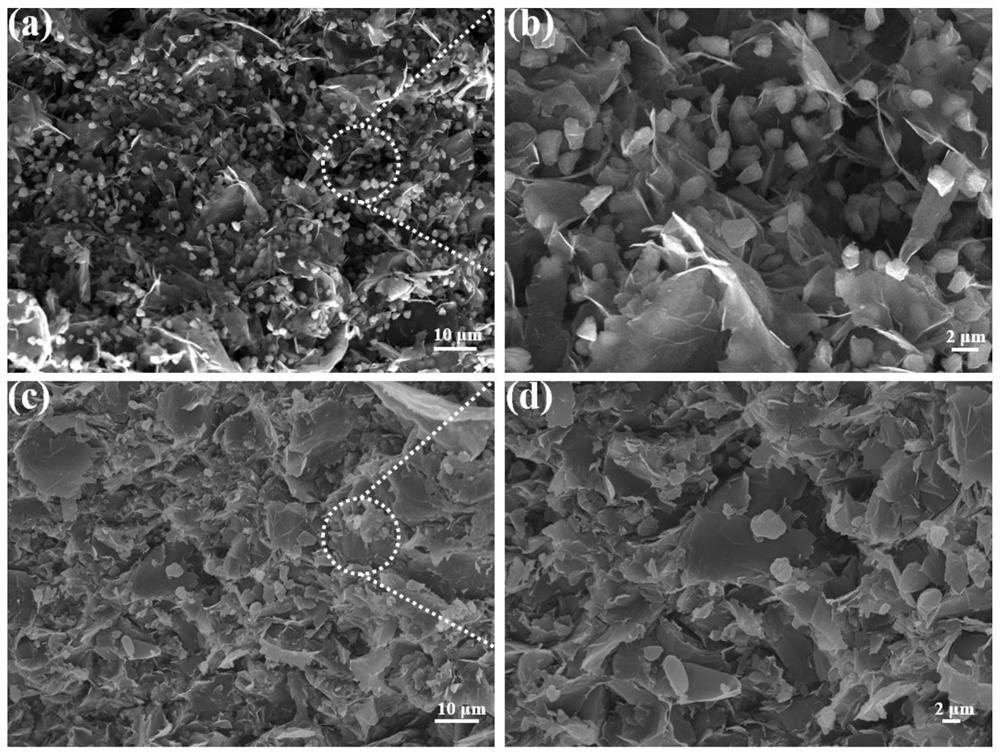

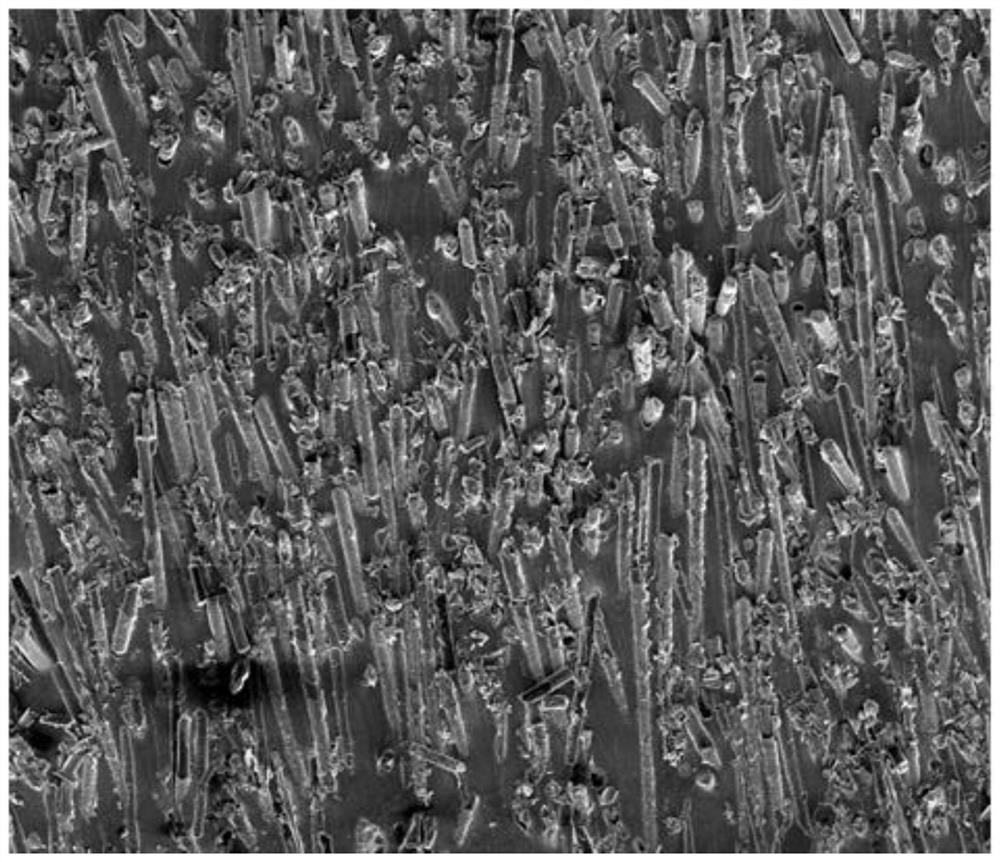

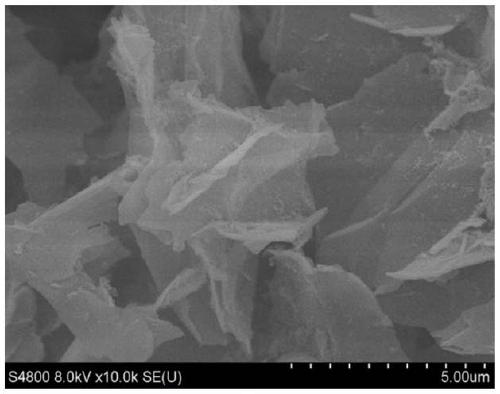

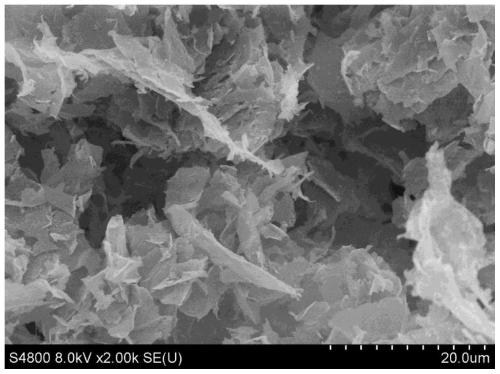

Directionally assembled graphene, graphene-carbon nano tube composite heat-conducting film and preparation method thereof

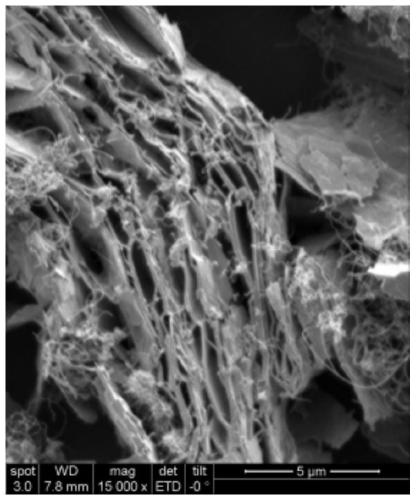

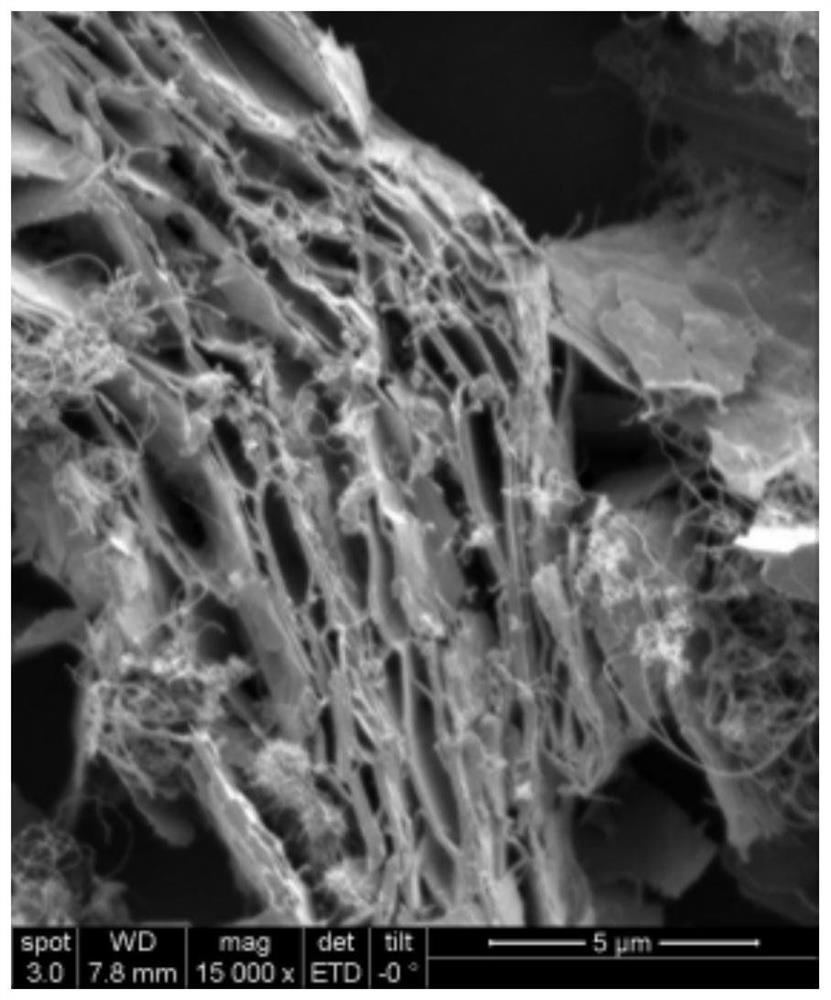

The invention relates to a preparation method of directionally assembled graphene. The preparation method comprises the following steps: mixing a graphene oxide aqueous solution and a water-soluble metal salt, slowly cooling until water molecules are crystallized into ice, carrying out a freeze drying treatment to obtain directionally assembled graphene oxide, and reducing to obtain directionallyassembled graphene loaded with metal nano particles. The directionally assembled graphene has a three-dimensional layered structure in which layers are arranged in parallel, an interlayer gap exists between the layers, and metal nano particles are riveted in the three-dimensional layered structure of the directionally assembled graphene. The invention also relates to directionally assembled graphene prepared by the above method. The invention further relates to a graphene-carbon nano tube composite heat-conducting film prepared from the directionally assembled graphene and a preparation methodthereof. The composite heat-conducting film has the advantages of low cost, high graphene phase selectivity, ultrahigh heat conduction coefficient, ultrahigh flexibility, controllable product thickness and the like, and the maximal vertical heat conduction coefficient can reach about 100W / (m.K).

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

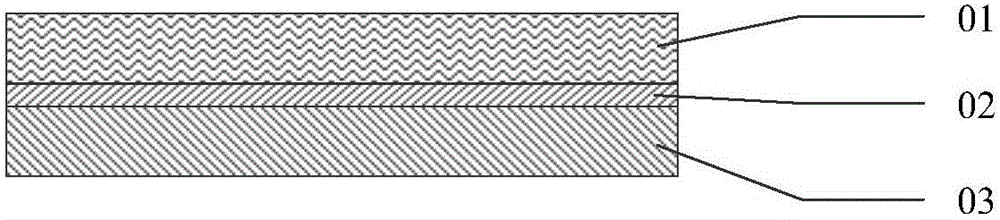

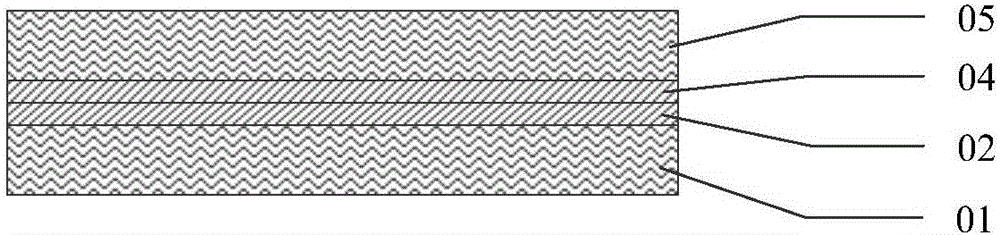

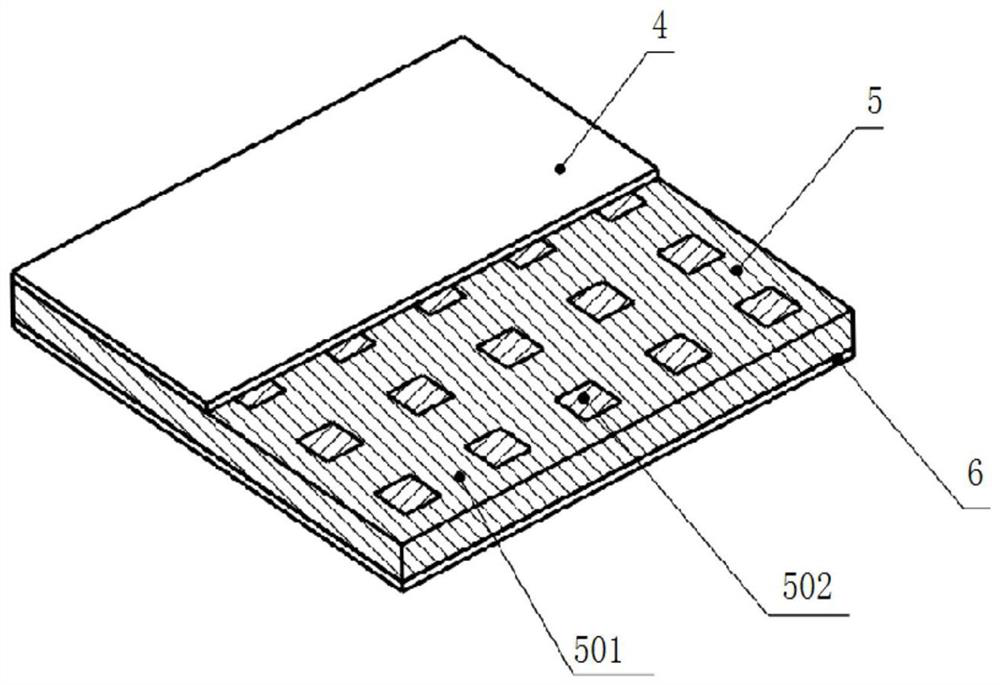

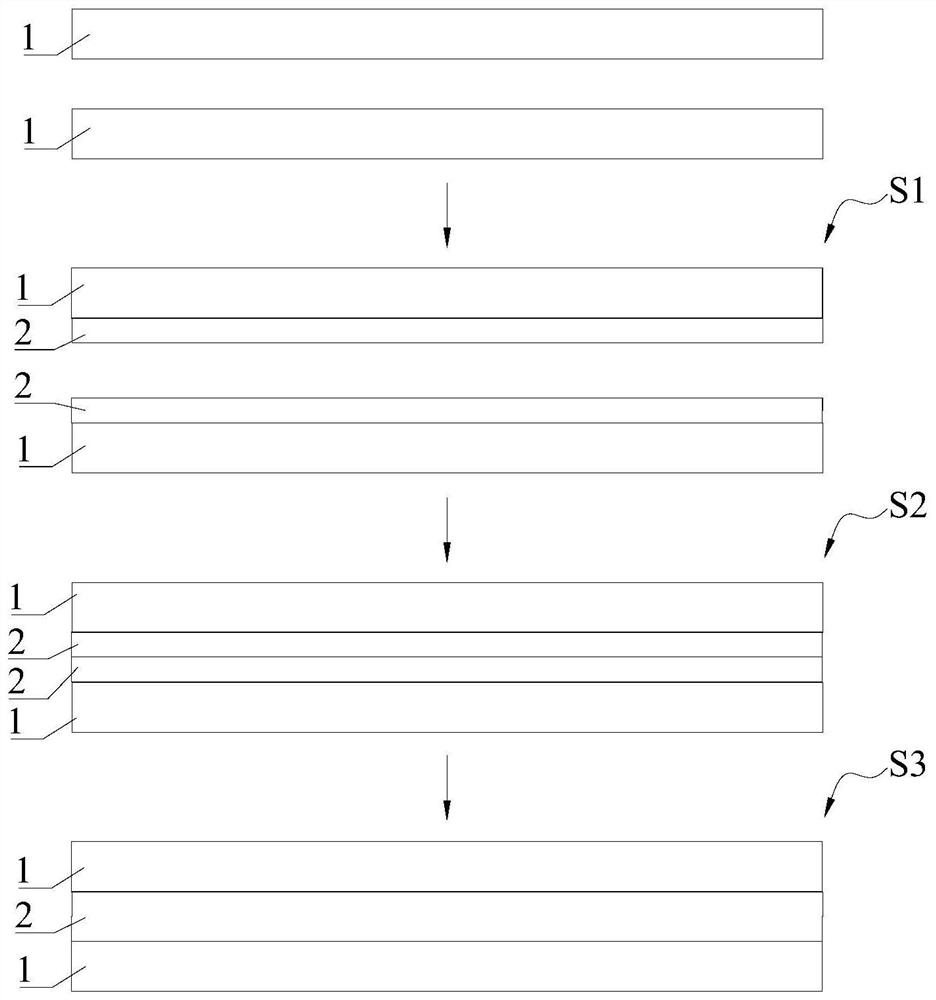

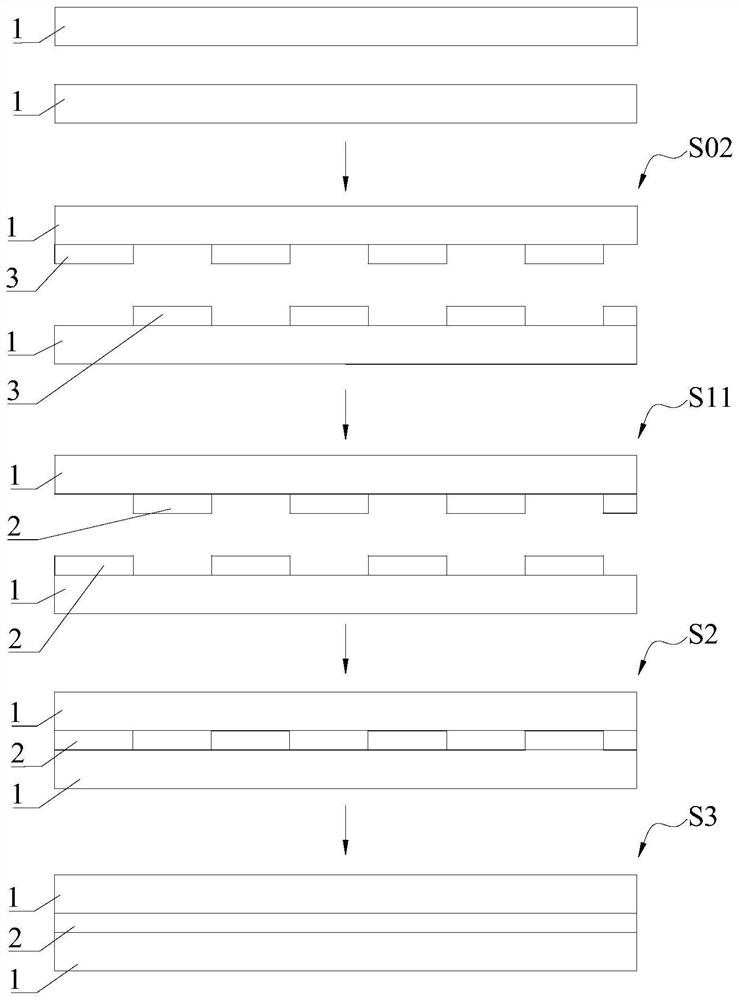

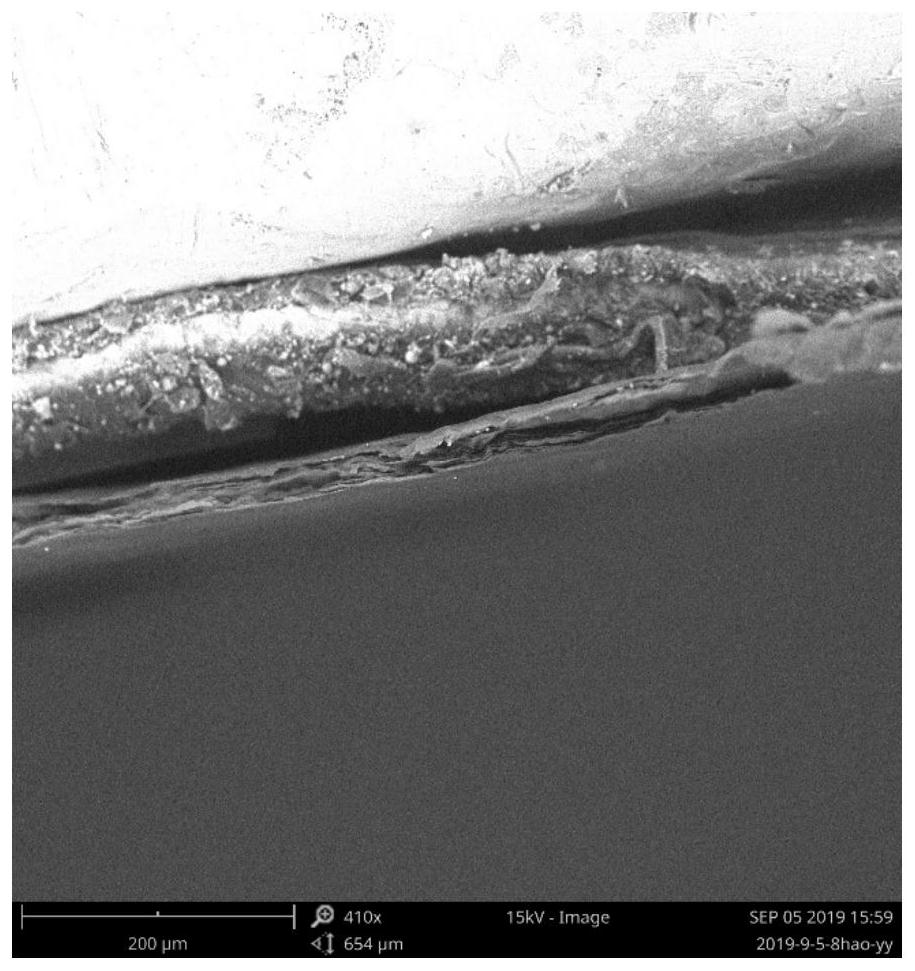

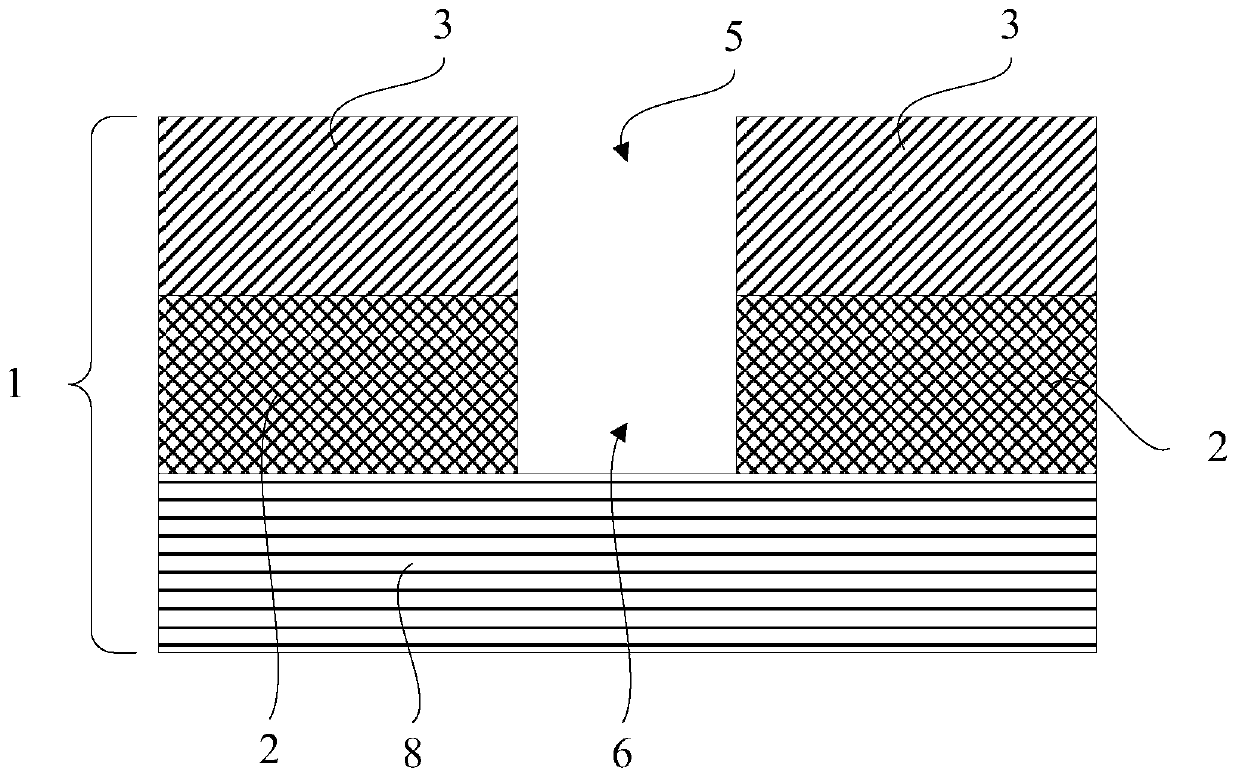

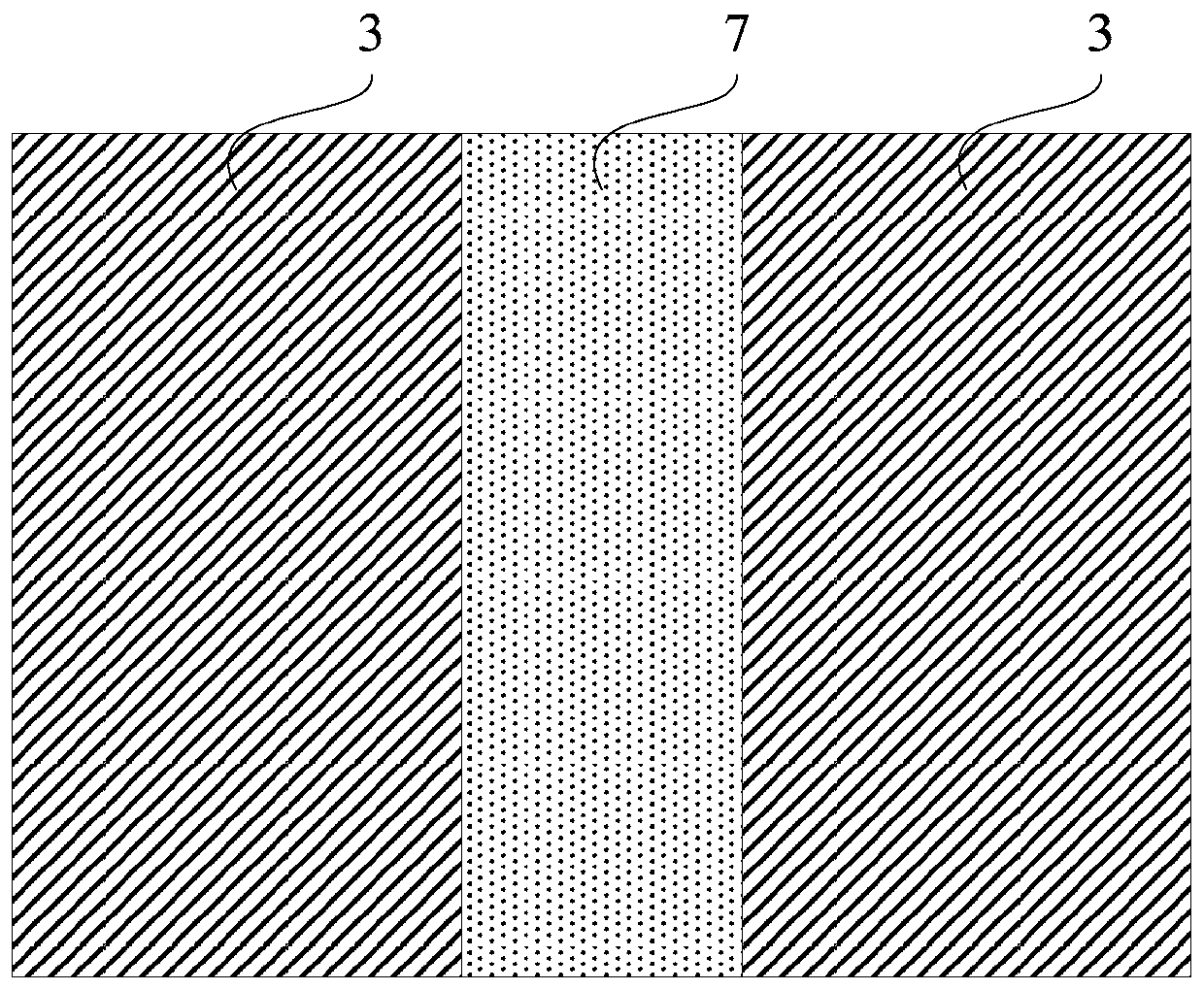

Graphite sheet and metal layer composed thermally conductive sheet and its composing method

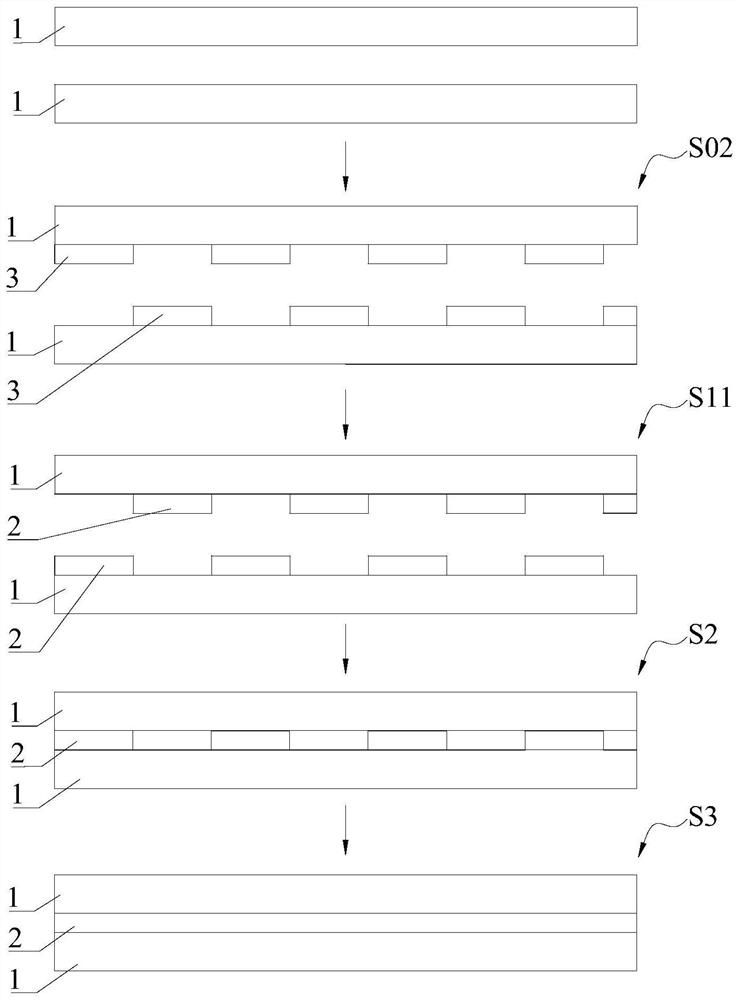

PendingCN106328614AGood thickness controllabilityIncrease heating capacitySemiconductor/solid-state device detailsSolid-state devicesDiffusion methodsGraphite

The invention provides a graphite sheet and metal layer composed thermally conductive sheet and its composing method. According to one embodiment of the invention, through a PVD aluminum deposition layer, the composition of a graphite sheet and other metal layers becomes possible so as to solve the difficulty with increasing the thickness of graphite sheet and thermally-conductive sheet and the problem of low thermal conductivity in the thickness direction. Based on these ideas, the invention aims to improve the overall heat capacity of the thermally conductive sheet and the comprehensive thermal conductivity in the thickness direction. The thermally conductive sheet of the invention can replace the product structure characterized by the adhesion of adhesive layers among multiple graphite sheet layers or between a graphite sheet and metal. Based on the prior art, the present invention combines the PVD aluminum plating technique and the metal hot-press diffusion method. Compared with the pure use of CVD or liquid plating method, the method of the invention is more efficient to obtain a composite metal layer with the same thickness. In addition, the once hard-to-obtain composite thickness and composite structure in the prior art can be more likely to be achieved. The composing method resolves the problem of how to accumulate composite metal layers with designated thicknesses and avoids the inherent defects of CVD and the liquid plating method.

Owner:SHENZHEN XINHENGKUN TECH

Thin-layer graphene/metal composite heat conducting film material and preparation method thereof, preparation method of metal salt intercalated graphene and electronic device

ActiveCN110740623AImprove the problem of low thermal conductivityThin layerGrapheneModifications by conduction heat transferHeat conductingGraphene flake

The invention relates to the field of graphene materials, in particular to a thin-layer graphene / metal composite heat conducting film material and a preparation method thereof, a preparation method ofmetal salt intercalated graphene and an electronic device. The method comprises the following steps: placing the sheet graphene and the heavy metal salt in a sealed environment, controlling the air pressure to be 0.05-0.2 atmosphere and heating and reacting; then forming a slurry; manufacturing the slurry into a heat conducting film and then graphitizing the heat conducting film; low air pressuretreatment is adopted in the intercalation process so that intercalation only exists at the edge of graphene and there is no intercalation inside graphene; the obtained graphene heat conducting film has metal intercalation in the vertical direction of the graphene sheet layer and the metal salt ions are reduced by graphite to form metal-carbon alloy after high temperature alloying and graphitization treatment and the graphene sheet layer is lapped up, wherein the existence of the metal-carbon alloy can improve the vertical thermal conductivity of the graphene thermal conducting film.

Owner:严帆

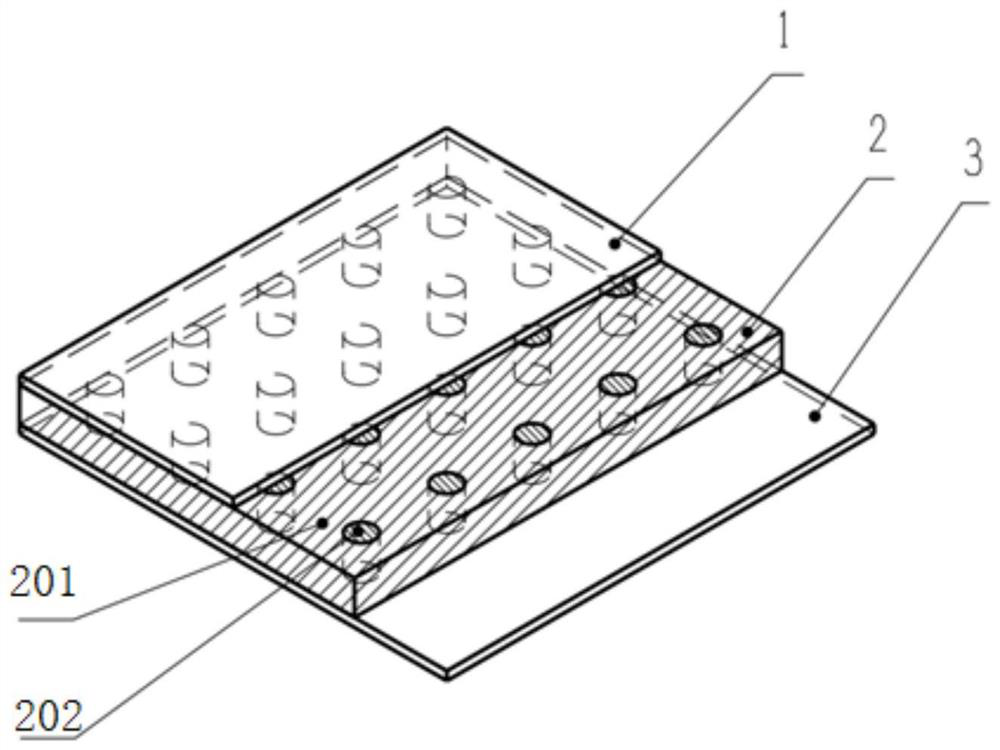

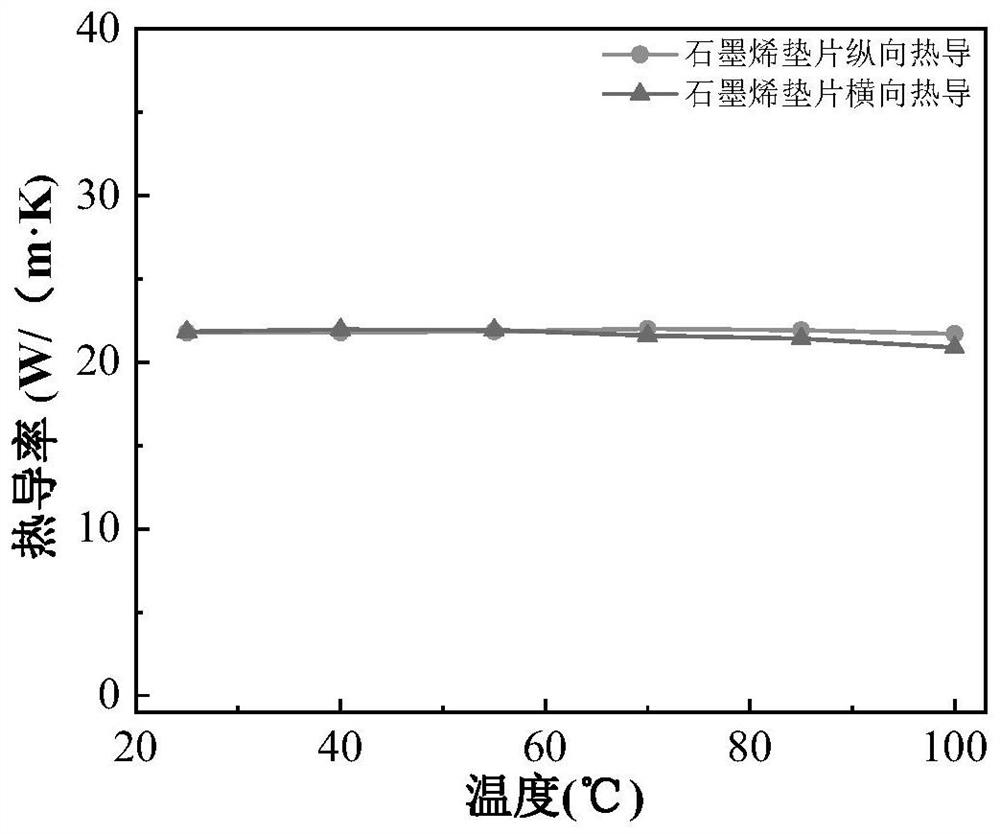

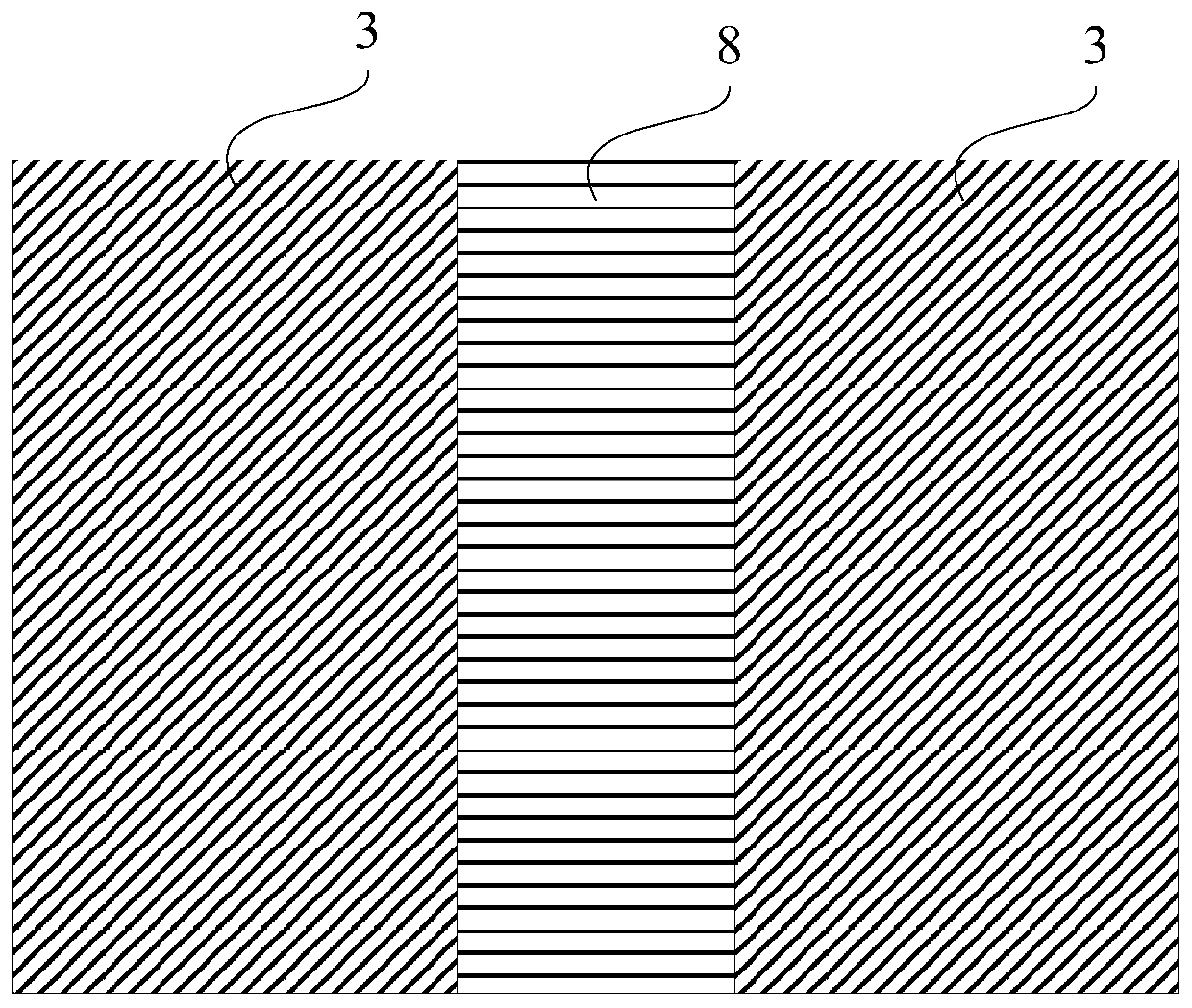

Aluminum-graphite aluminum composite material structure capable of enhancing longitudinal heat conductivity coefficient

InactiveCN112339359AImprove longitudinal thermal conductivityRaise the boundaries of the applicationElectrical equipmentModifications by conduction heat transferGraphiteAluminum composites

The invention provides an aluminum-graphite-aluminum composite material structure capable of enhancing a longitudinal heat conductivity coefficient, and belongs to the technical field of composite materials. The composite material structure comprises an upper aluminum coating layer, a composite graphite aluminum functional layer and a lower aluminum coating layer which are fused together by adopting a metallurgical method, the composite graphite aluminum functional layer comprises a graphite aluminum layer and a plurality of heat conduction columns embedded in the graphite aluminum layer, andthe material of the heat conduction columns is consistent with the material of the upper aluminum coating layer and the material of the lower aluminum coating layer. According to the aluminum-graphite-aluminum composite material structure, the longitudinal heat conductivity coefficient of the graphite aluminum is greatly improved by adding the heat conduction columns in the graphite aluminum layer, and compared with an existing common graphite aluminum material, the transverse heat conductivity coefficient of the aluminum-graphite-aluminum composite material structure with the enhanced longitudinal heat conductivity coefficient is basically consistent with that of the graphite aluminum; the longitudinal heat conductivity coefficient is greatly improved, and the application boundary of thegraphite aluminum in the thermal design of electronic equipment can be greatly improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

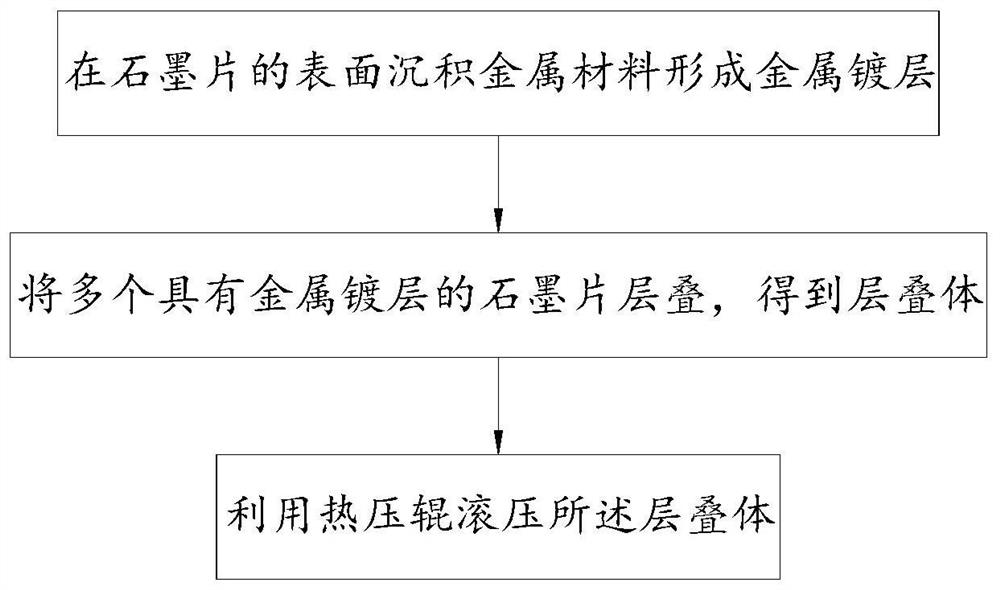

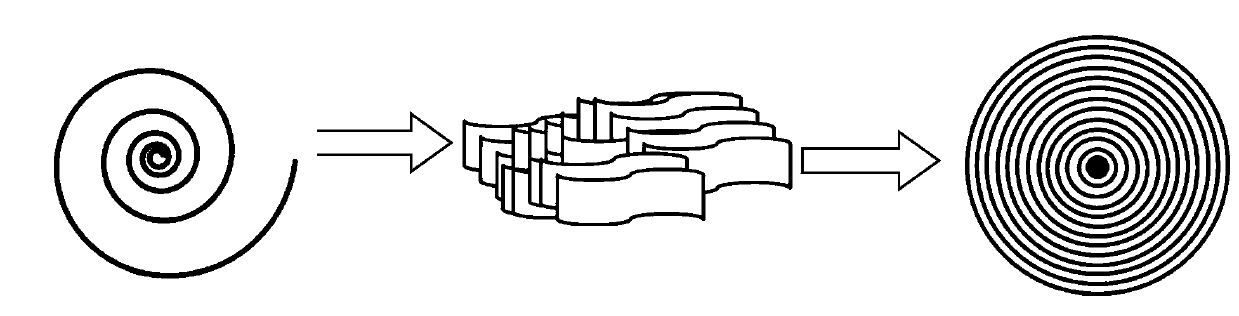

Graphite composite radiating fin and preparation method thereof

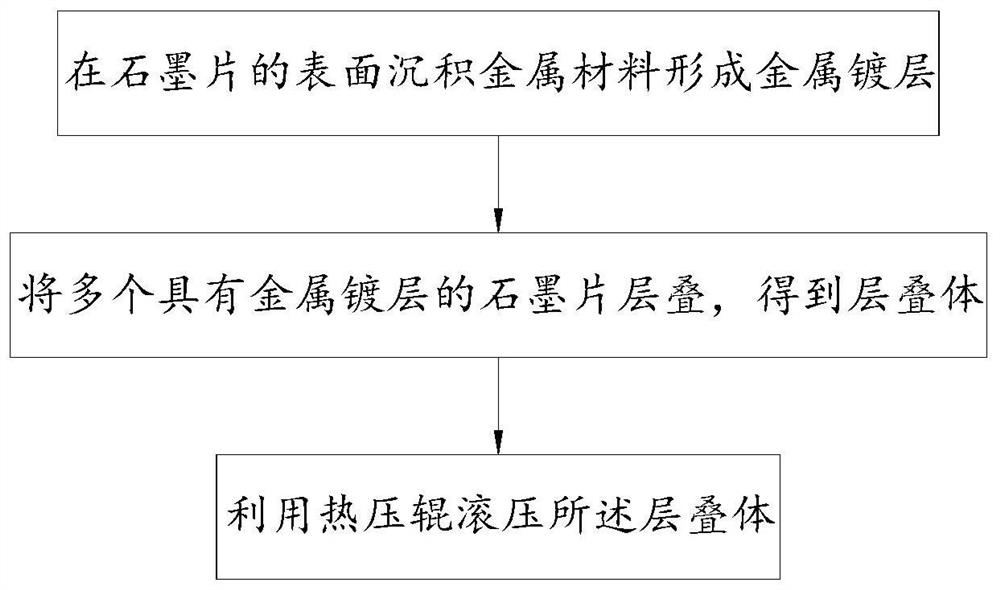

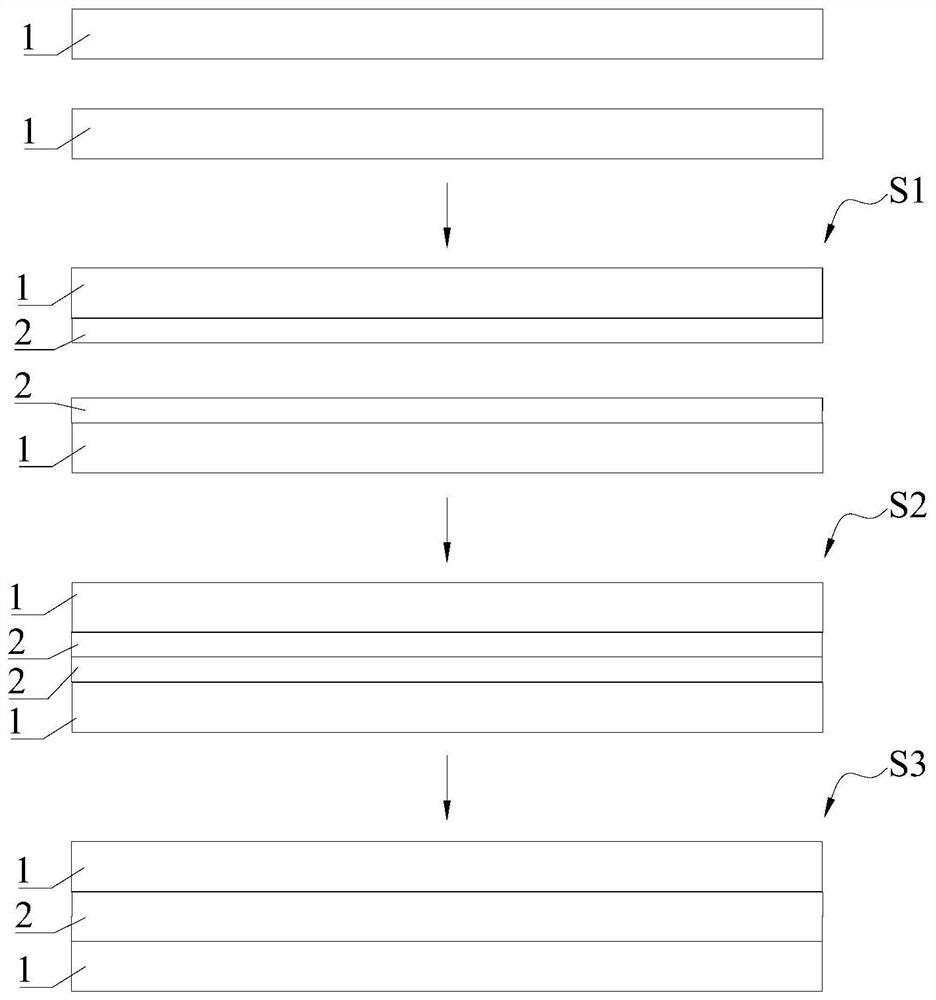

ActiveCN111823664AMaintain thermal advantageImprove longitudinal thermal conductivityLamination ancillary operationsLaminationAdhesive cementMetallic materials

The invention discloses a graphite composite radiating fin and a preparation method thereof. The preparation method of the graphite composite radiating fin comprises the following steps of: depositinga metal material on the surface of a graphite flake to form a metal plating layer; laminating a plurality of graphite flakes with metal plating layers to obtain a laminate; and rolling the laminate with a hot press roller. The graphite composite radiating fin prepared by the preparation method of the graphite composite radiating fin has no adhesive inside, two adjacent layers of graphite flakes are in hot-pressing connection through the low-melting-point metal plating layers on the surfaces of the graphite flakes, thus reaching the purpose of acquiring the thick graphite composite radiating fin, the heat conduction advantage of the graphite composite radiating fin in the horizontal direction can be kept, the longitudinal heat conduction performance of the graphite composite cooling fin can be improved, the heat conduction effect of the graphite composite radiating fin is extremely excellent, and the graphite composite radiating fin is simple in preparation process and low in cost.

Owner:SHENZHEN HANKE NEW MATERIAL TECH CO LTD

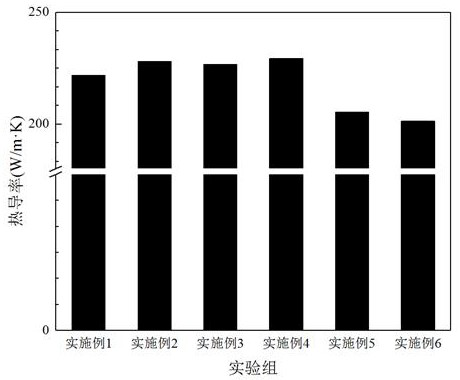

Preparation method of high-thermal-conductivity graphite aerogel-based composite thermal interface material

ActiveCN112708152AEffective distributionSolve the bottleneck problem of heat dissipationModifications by conduction heat transferFreeze-dryingBottle neck

The invention discloses a preparation method of a high-thermal-conductivity graphite aerogel-based composite thermal interface material, and relates to a thermal interface material. The preparation method comprises the following steps of: adding ascorbic acid into deionized water, and stirring to obtain a uniform ascorbic acid solution; stirring, adding a GO aqueous solution, transferring the obtained mixed solution into a reaction kettle lining, sealing the reaction kettle lining, putting the reaction kettle lining into a stainless steel shell, and reacting in a blast drying oven; transferring a reaction product from the reaction kettle lining into other containers, and repeatedly cleaning the reaction product with deionized water and ethanol; freezing a cleaned sample, and then transferring the frozen sample into a freeze dryer for drying; putting the sample into a mold, compressing the sample by using a certain pressure, and then pouring a prepared polymer solution into the mold; drying the sample in a vacuum drying oven; and demolding the dried sample from the mold to obtain the high-thermal-conductivity graphite aerogel-based composite thermal interface material. The composite thermal interface material is high in longitudinal heat conductivity, good in mechanical property, capable of achieving self-supporting and easy to store, and the bottleneck problem of heat dissipation of electronic products is expected to be solved.

Owner:XIAMEN UNIV

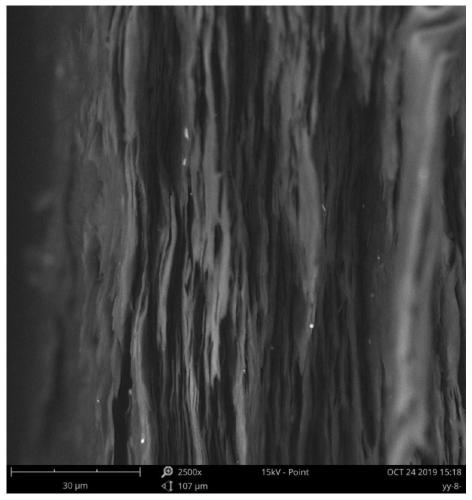

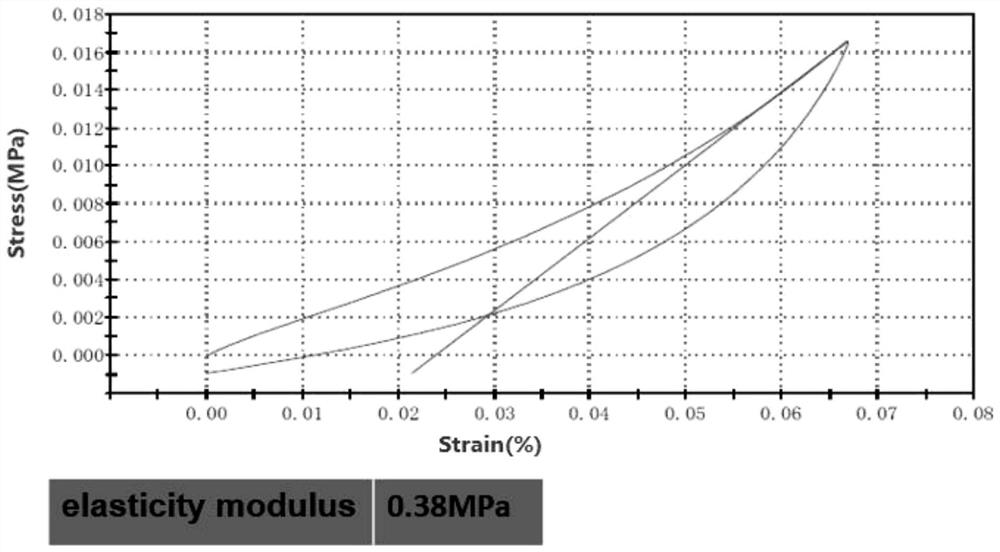

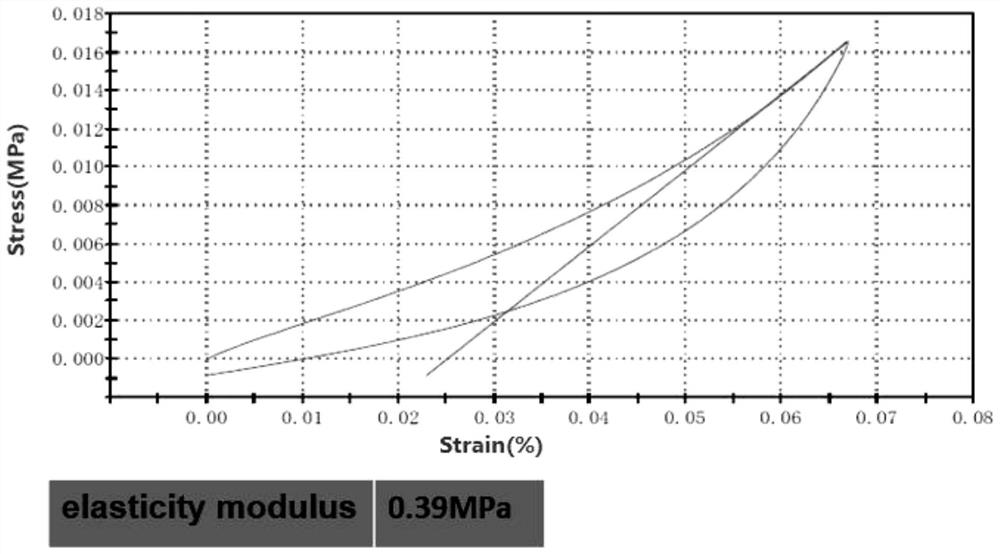

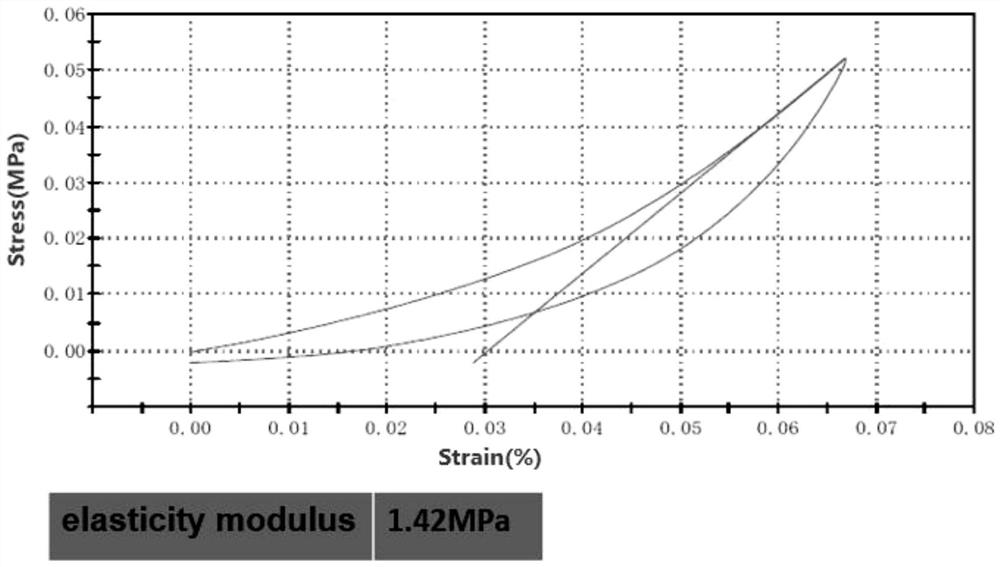

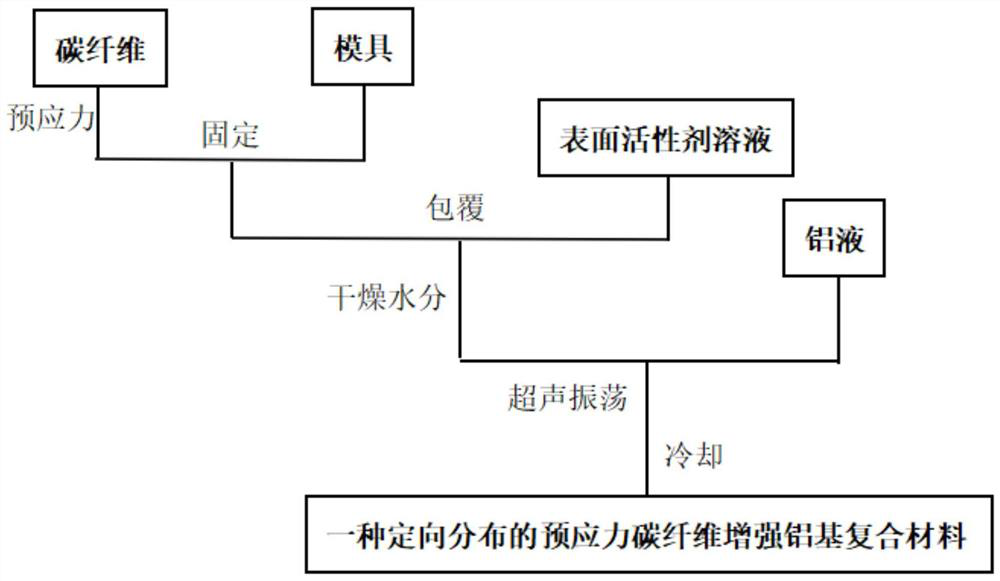

Preparation method of directionally distributed prestressed carbon fiber reinforced aluminum matrix composite

ActiveCN112143986AFacilitated DiffusionReduce interfacial tensionWeight reductionConjugated artificial filamentsCarbon fibersAluminium matrix

The invention relates to the field of aluminum alloy preparation, and discloses a preparation method of a directionally distributed prestressed carbon fiber reinforced aluminum matrix composite. The preparation method of the directionally distributed prestressed carbon fiber reinforced aluminum matrix composite comprises the following steps of (1) applying pretension to carbon fibers arranged in the same direction, and fixing with a mold to obtain directionally arranged carbon fibers; (2) pouring an aqueous solution of a surfactant into the mold, fully infiltrating, and drying to obtain the carbon fibers coated with the surfactant; and (3) pouring molten aluminum into the mold, carrying out ultrasonic oscillation, and then cooling to obtain the carbon fiber reinforced aluminum matrix composite. According to the preparation method provided by the invention, the carbon fibers are coated with the surfactant, so that the compatibility between the carbon fibers and an aluminum matrix can beeffectively improved, and the mechanical property and the heat-conducting property of the composite are improved.

Owner:丽水正阳电力建设有限公司 +3

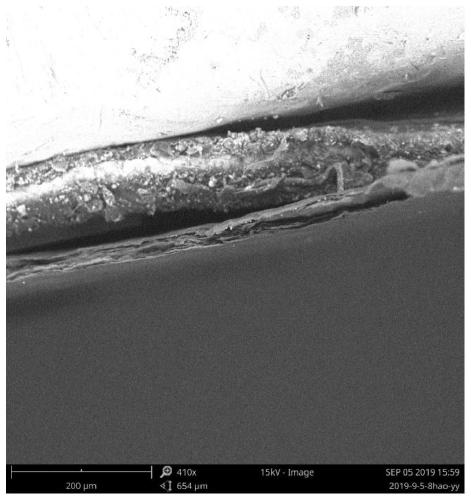

Carbon cooling fin and preparation method thereof

ActiveCN111818764AImprove longitudinal thermal conductivityImprove cooling efficiencyNon-macromolecular adhesive additivesCarbon compoundsRough surfaceSemiconductor materials

The invention relates to the technical field of semiconductor materials, and especially relates to a carbon cooling fin and a preparation method thereof. The cooling fin comprises a graphene film layer and an aluminum foil layer, the graphene film layer and the aluminum foil layer are connected through a heat conduction adhesive, the graphene film layer is an ionic liquid modified graphene film layer, and the contact surface of the aluminum foil layer and the heat conduction adhesive is a rough surface. An ionic liquid is adopted to modify a graphene layer to improve the longitudinal thermal conductivity of the graphene layer to a certain extent, and the overall heat dissipation efficiency of the carbon cooling fin is further improved in combination with the aluminum foil layer, so that the carbon cooling fin is suitable for more precise electronic products with higher heat dissipation requirements. Due to the structural design that the contact surface of the aluminum foil layer and the heat conduction adhesive is the rough surface and the rough surface is arranged on the aluminum foil layer, the contact area between the aluminum foil layer and the heat conduction adhesive is increased, and the bonding strength between the aluminum foil layer and the heat conduction adhesive is improved, so that the overall heat dissipation efficiency of the carbon cooling fin is improved.

Owner:江苏中商碳素研究院有限公司

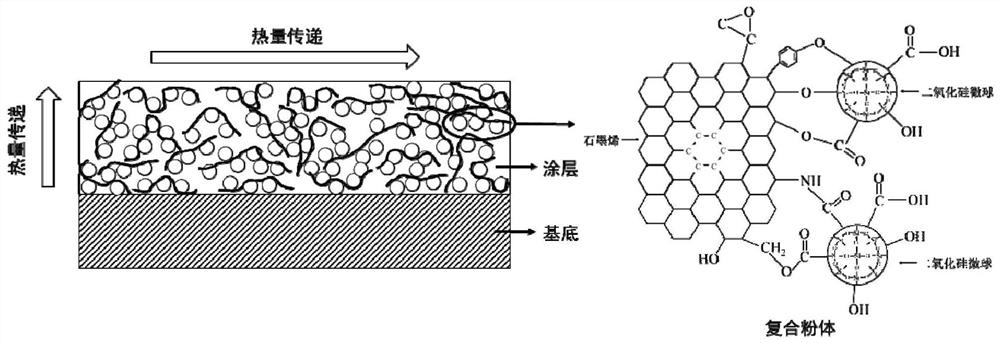

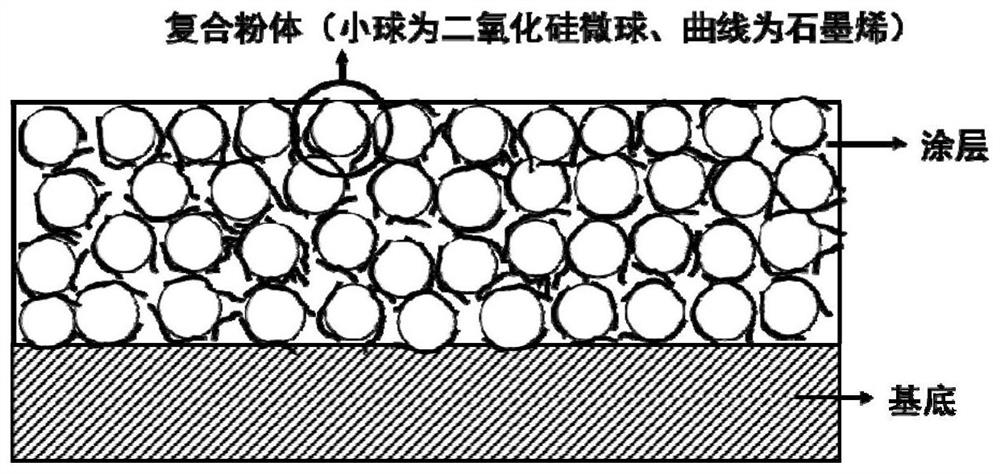

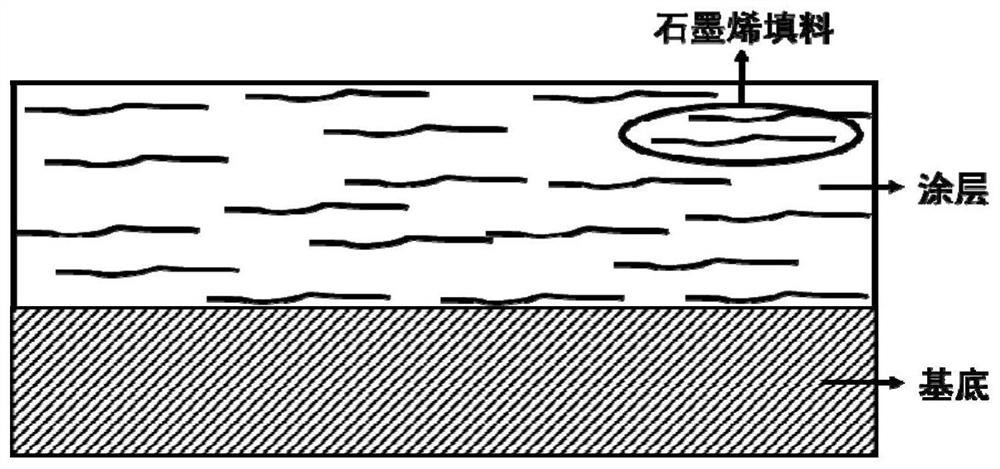

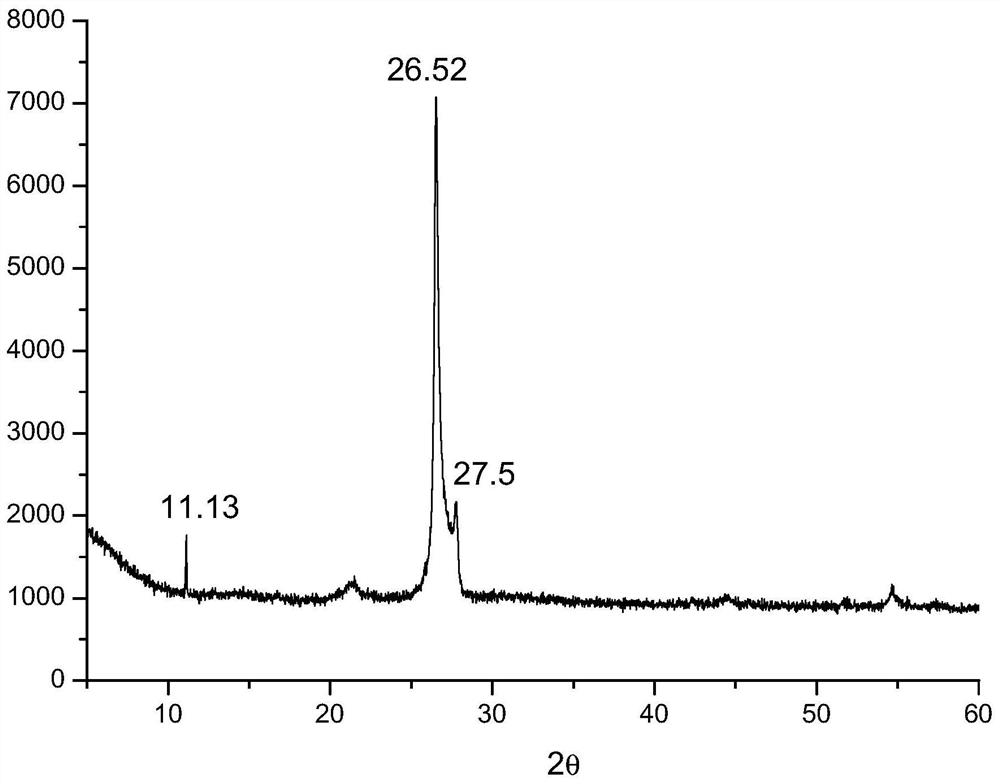

Composite powder, preparation method thereof and application of composite powder in heat dissipation coating

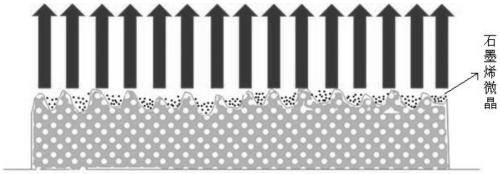

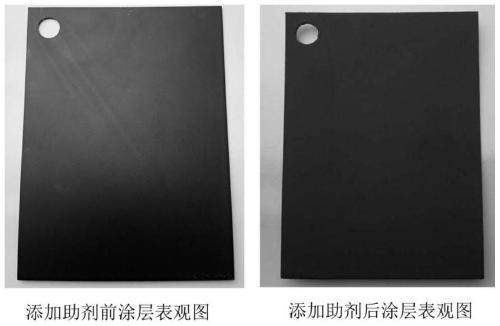

PendingCN114874656AImprove thermal conductivityImprove longitudinal thermal conductivityHeat-exchange elementsEpoxy resin coatingsMicrosphereGraphite

The invention relates to composite powder which comprises graphene and silicon dioxide microspheres, the graphene and the silicon dioxide microspheres are combined together through chemical bonds, the average transverse size of the graphene is 5-30 [mu] m, and the particle size of the silicon dioxide microspheres is 0.5-20 [mu] m. The invention also relates to a preparation method of the composite powder and an application of the composite powder in a heat dissipation coating, and the application comprises the following steps: providing a heat dissipation coating through the composite powder, and then enabling the heat dissipation coating to form the heat dissipation coating. According to the composite powder and the silicon dioxide microspheres, the heat resistance of the coating can be improved, agglomeration of the graphene can be hindered, the dispersity of the graphene in the coating can be improved, the orientation distribution of the graphene in the coating can be changed, the orientation proportion in the direction perpendicular to a substrate is increased, and the heat resistance of the coating is improved. Therefore, the coating has excellent transverse and longitudinal heat-conducting properties at the same time.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

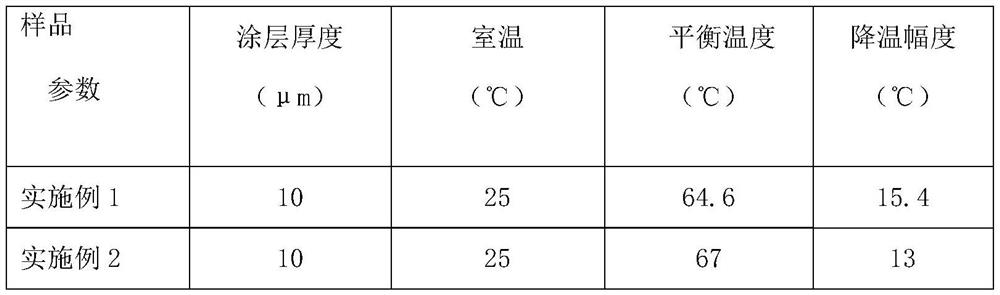

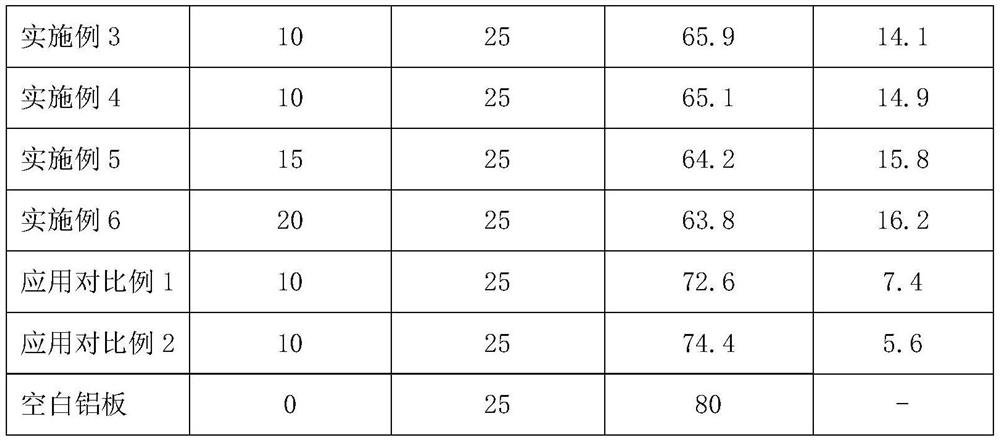

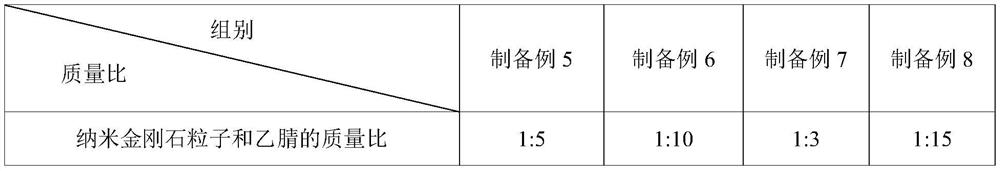

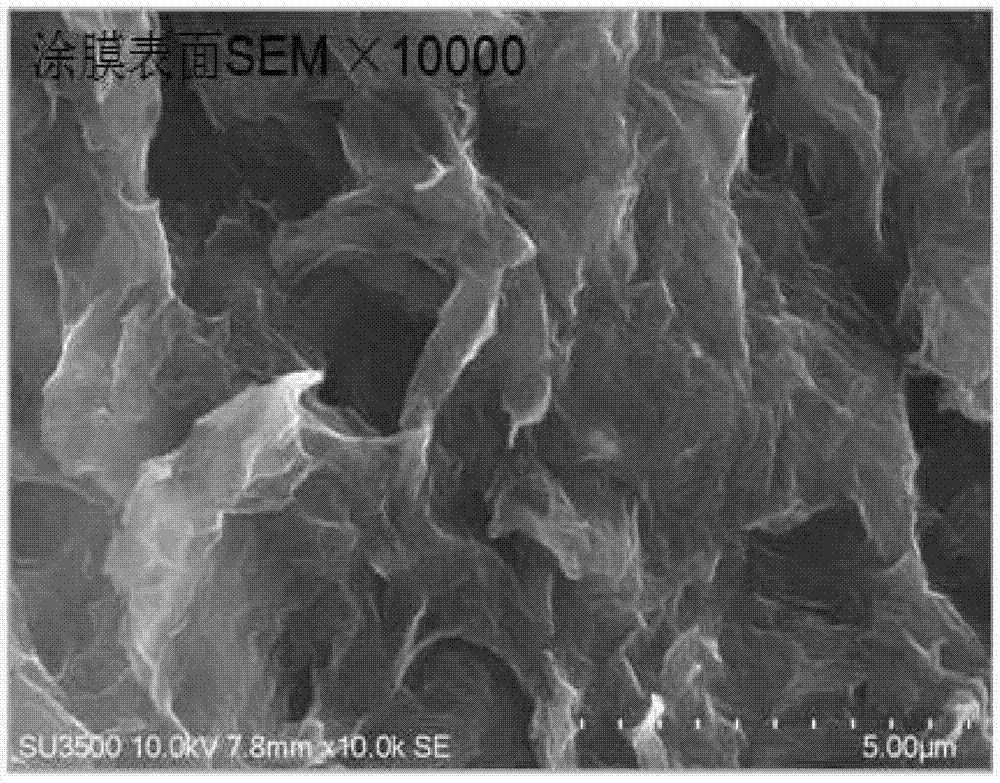

Nano interlayer graphene heat dissipation coating and preparation method and application thereof

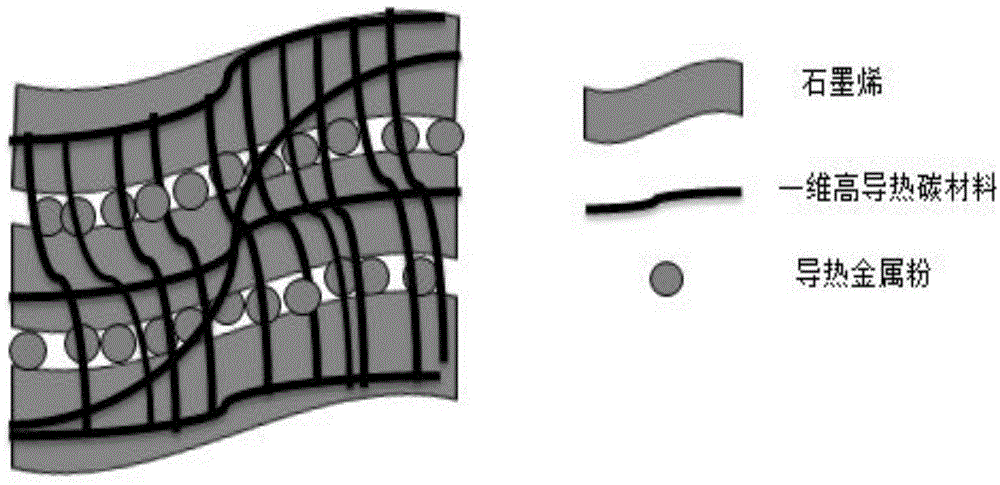

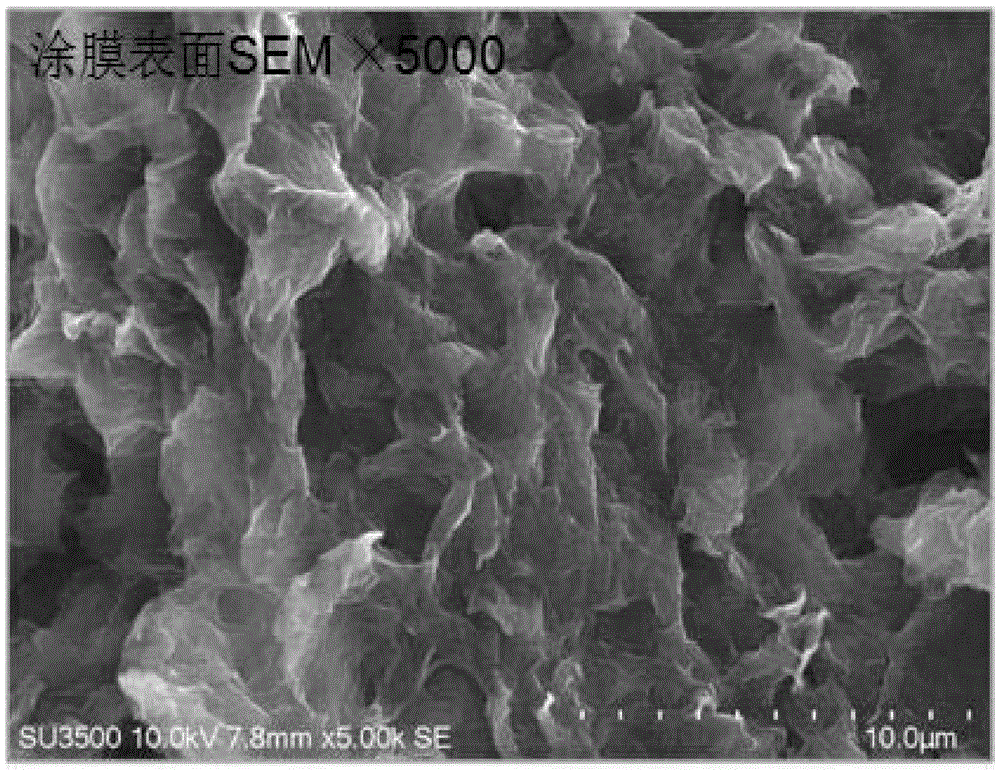

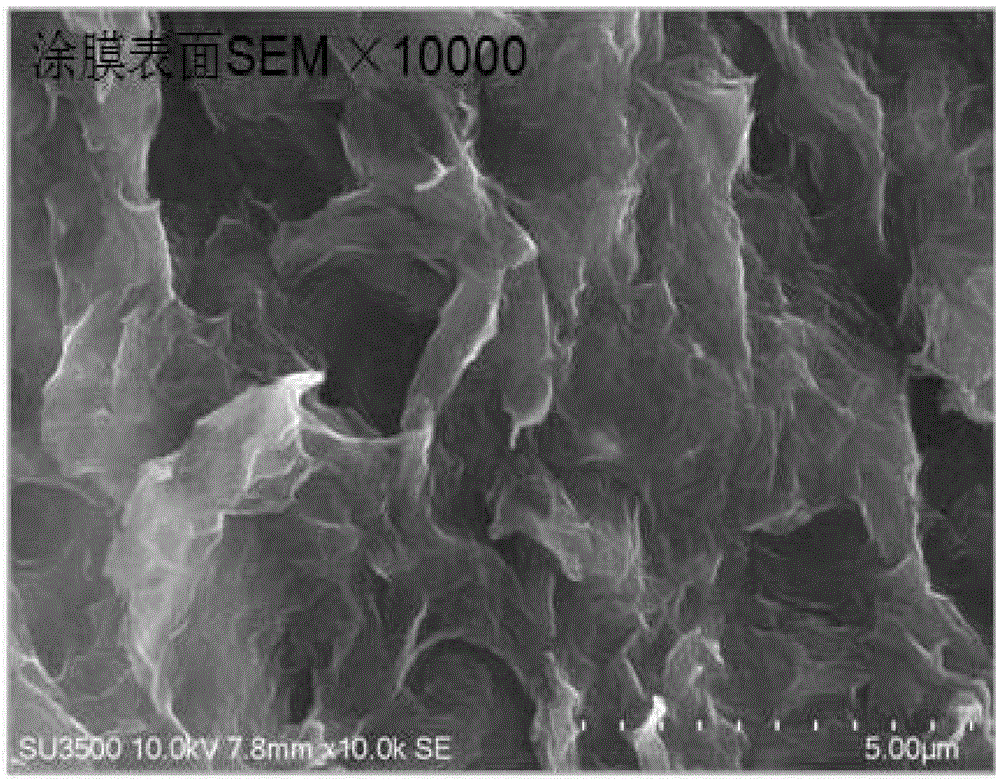

InactiveCN111826043AImprove the disadvantage of being difficult to disperse evenlyImprove cooling effectAnti-corrosive paintsPolyurea/polyurethane coatingsNanowirePolymer resin

The invention discloses a nano interlayer graphene heat dissipation coating and a preparation method and application thereof, and relates to the field of heat dissipation materials. According to the invention, the zero-dimensional spherical nano-filler and the one-dimensional linear nano-filler are arranged between the layers of the graphene material in an intercalation manner so that the defectsthat the graphene is easy to agglomerate and is difficult to disperse uniformly in polymer resin are greatly improved. Moreover, the prepared nano interlayer graphene composite material (graphene material-one-dimensional nanowire-zero-dimensional nanosphere compound) has the advantages that the longitudinal heat conductivity of graphene is greatly improved; meanwhile, no matter how the graphene material-one-dimensional nanowire-zero-dimensional nanosphere compound is distributed in the resin matrix, a three-dimensional heat conduction channel can be effectively established; therefore, the temperature of the heat source can be transmitted to the superficial surface and the surface of the coating more quickly, heat can be dissipated more quickly in an infrared radiation mode, and the main purpose of reducing the temperature of the heating core more quickly is achieved.

Owner:武汉联维新材料科技有限公司

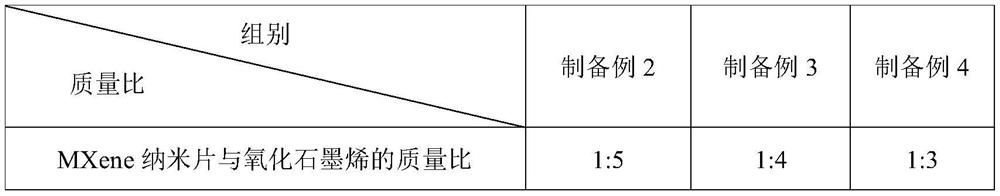

Three-dimensional heat-conducting and wave-absorbing reinforced composite film and preparation method thereof

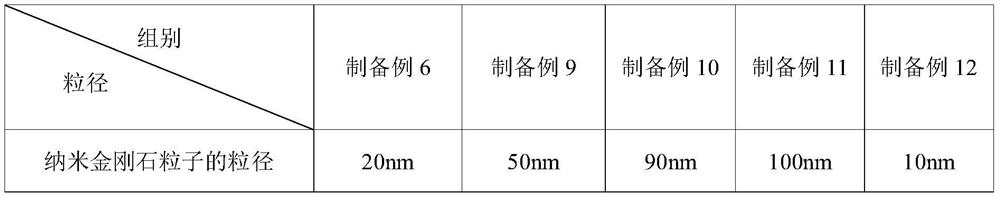

ActiveCN114031074AImprove thermal conductivityImprove absorbing performanceChemical industryDiamondPolymer scienceLaser array

The invention discloses a three-dimensional heat-conducting and wave-absorbing reinforced composite film and a preparation method thereof. The three-dimensional heat-conducting and wave-absorbing reinforced composite film comprises a graphene oxide / MXene film, a plurality of through holes penetrating through the upper surface and the lower surface of the graphene oxide / MXene film are formed in the graphene oxide / MXene film, and graphene-coated nano-diamond particles are arranged in the through holes in a penetrating mode. The preparation method comprises the following steps: S1, mixing the graphene-coated nano diamond particles, the silane coupling agent and the solvent, and ultrasonically dispersing uniformly; s2, performing laser array punching on the graphene oxide / MXene film; and S3, pouring a solution containing the graphene-coated nano diamond particles into the through holes, and drying. The three-dimensional heat-conducting and wave-absorbing reinforced composite film not only has an ultrahigh heat conductivity coefficient in the transverse direction, but also has a relatively high heat conductivity coefficient in the longitudinal direction, and also has good wave-absorbing performance and good mechanical strength.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Graphite aluminum high-thermal-conductivity module with low longitudinal thermal resistance

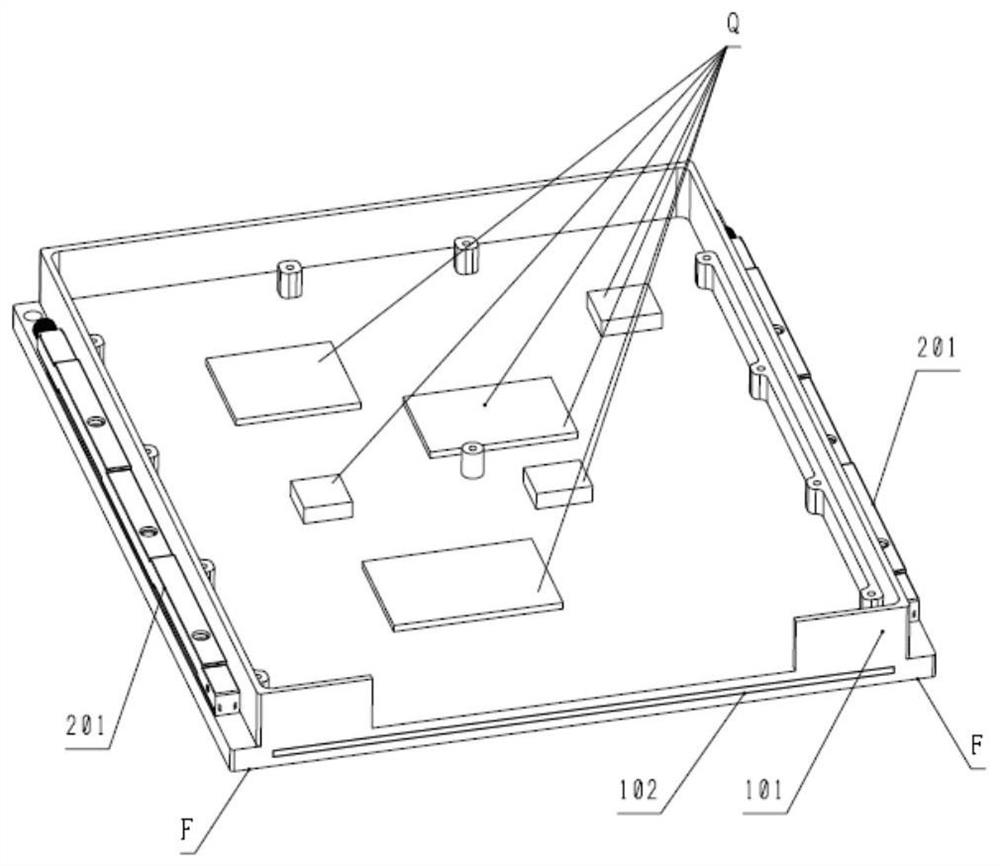

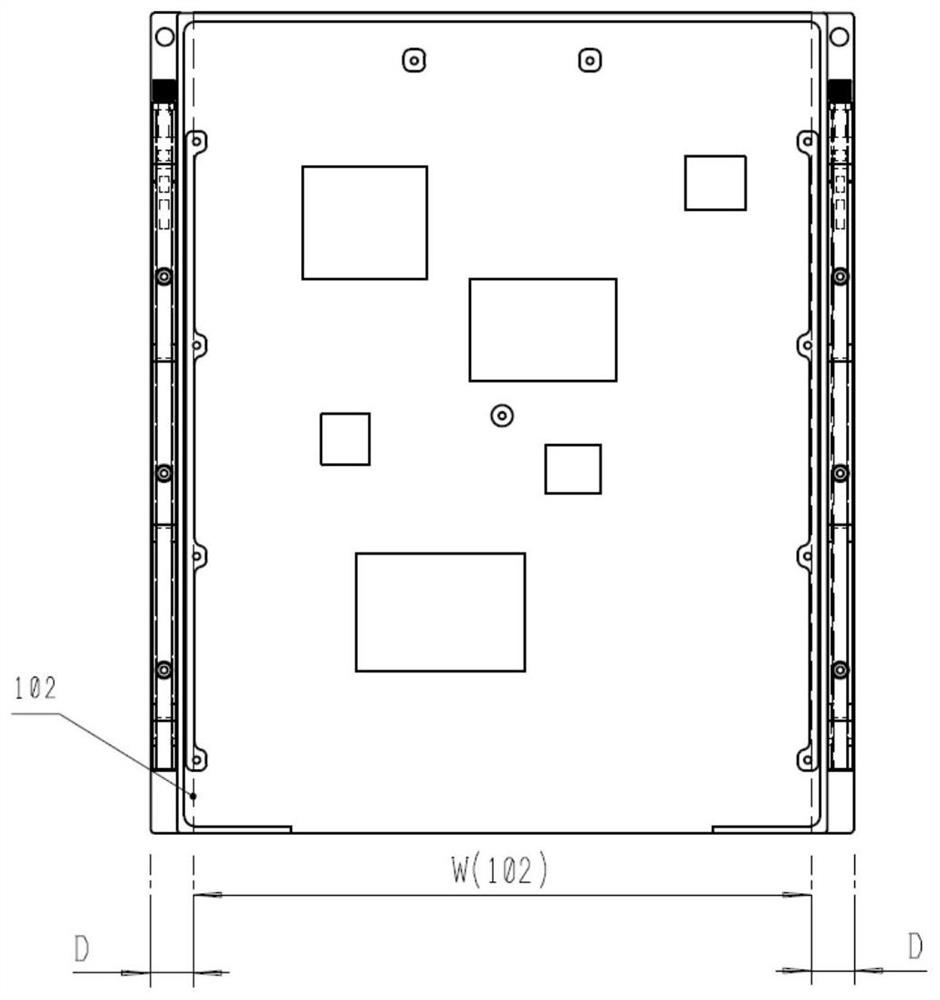

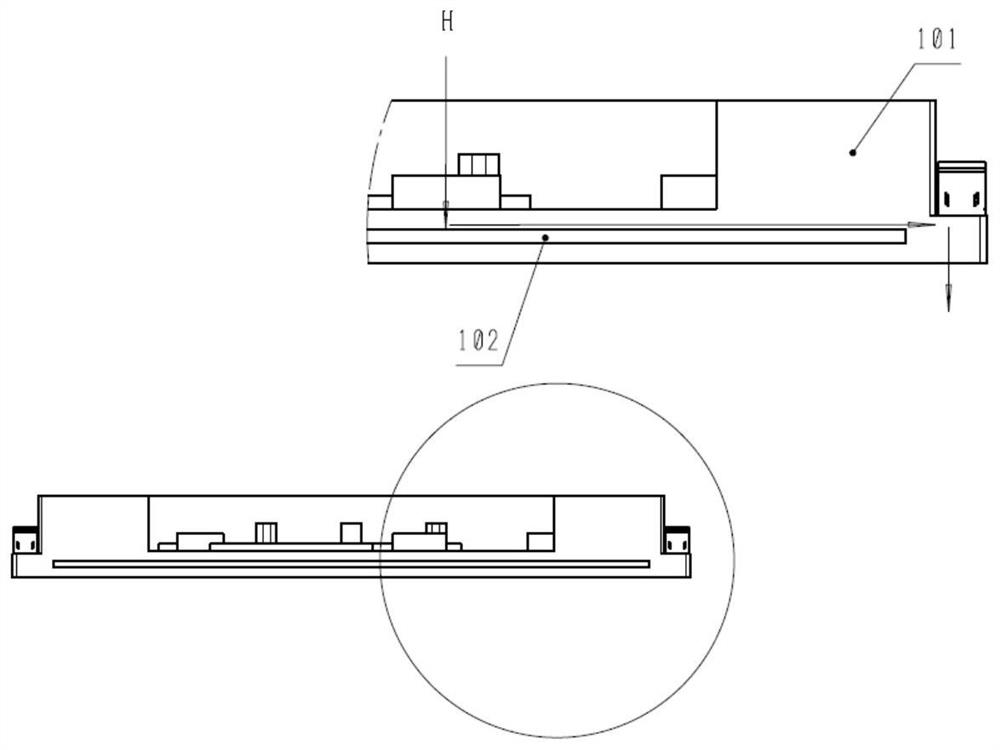

ActiveCN113438864AImprove longitudinal thermal conductivityHigh thermal conductivityModifications by conduction heat transferPhysicsThermal conductivity

The invention discloses a graphite aluminum high-thermal-conductivity module with low longitudinal thermal resistance, which comprises a box body and a plurality of upper bosses arranged on the upper surface of the box body, a high-thermal-conductivity interlayer is embedded in the box body, locking strips are arranged on two sides of the box body, and the back side surfaces of the locking strips of the box body are external heat exchange surfaces of the box body. The module is characterized in that the high-heat-conduction interlayer is not fully paved in the box body, and the external heat exchange surfaces on the two sides are not fully paved with high-heat-conduction structures. According to the graphite aluminum high-thermal-conductivity module, the structure of an existing graphite aluminum high-thermal-conductivity module is improved, longitudinal thermal resistance is reduced, the longitudinal thermal conductivity of the graphite aluminum high-thermal-conductivity module is improved, and the overall thermal conductivity of the graphite aluminum high-thermal-conductivity module is enhanced.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP +1

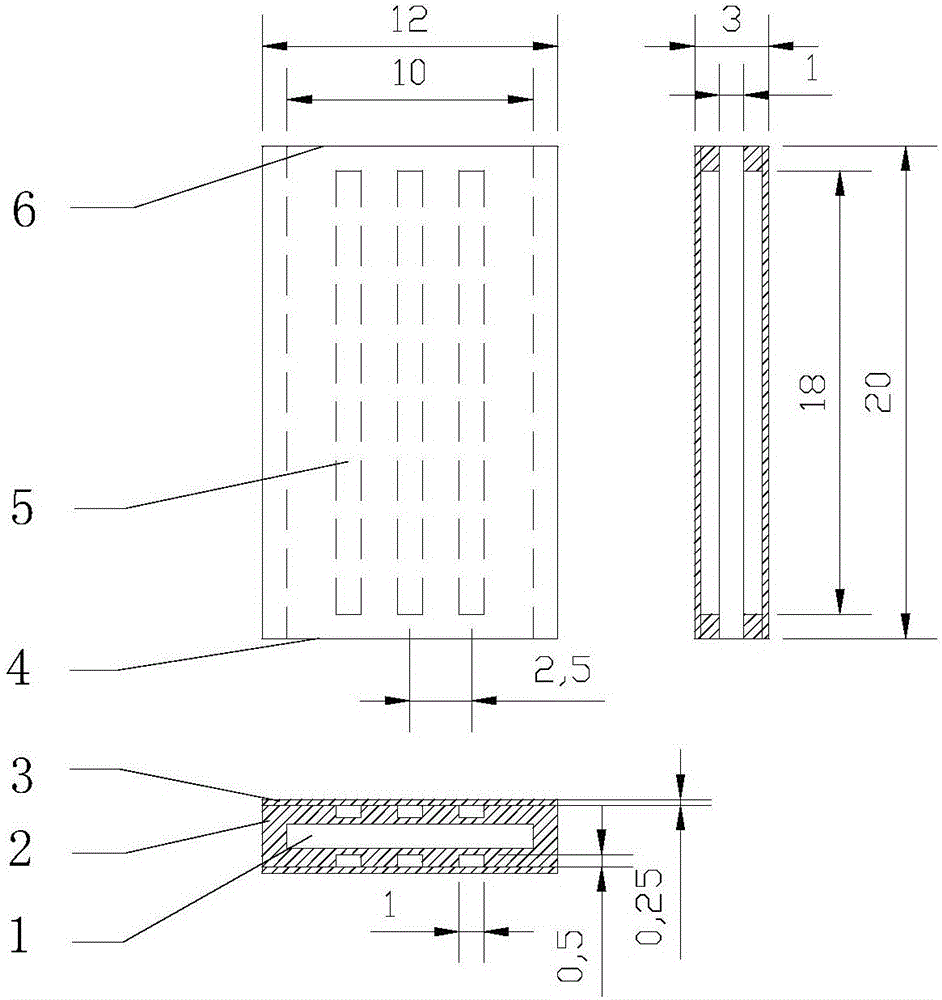

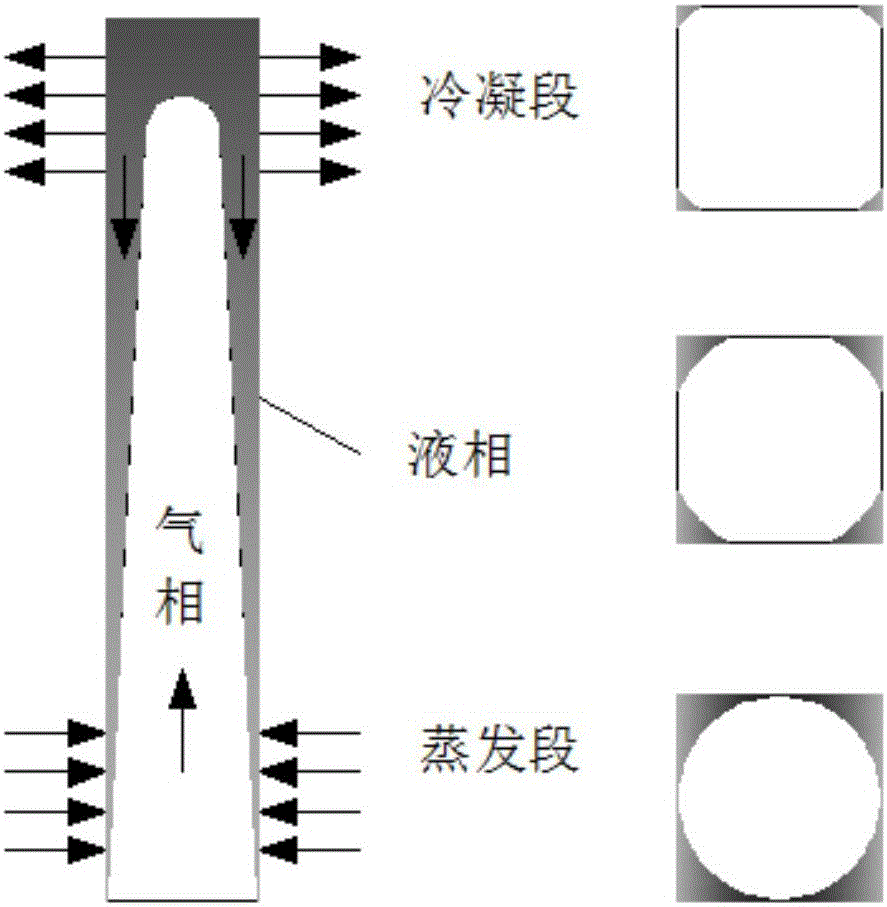

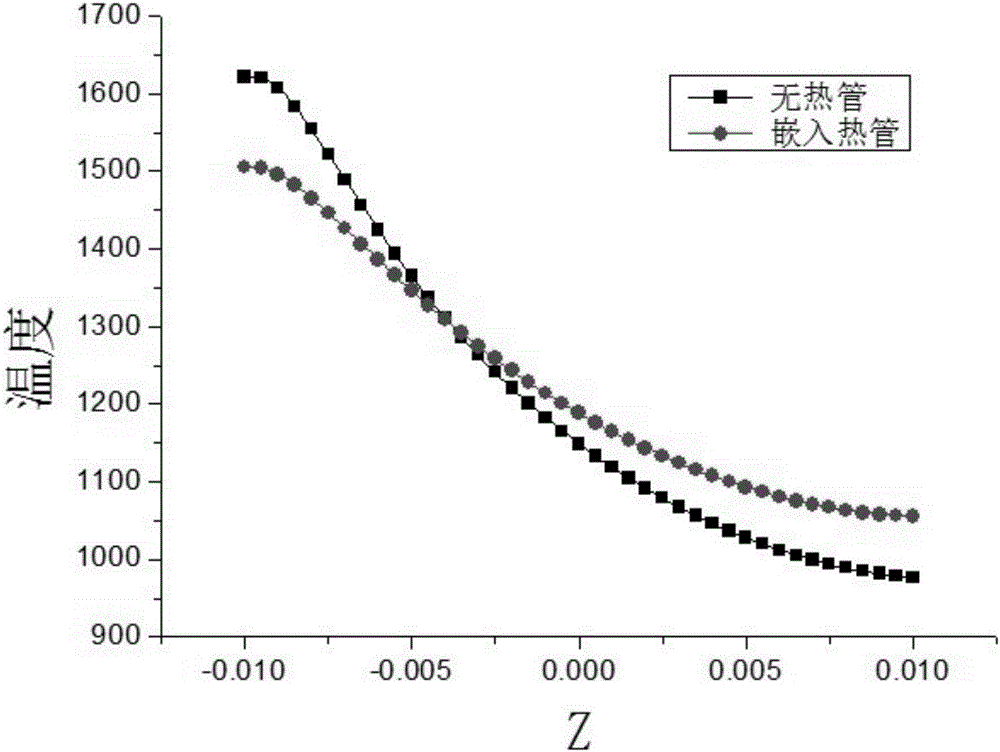

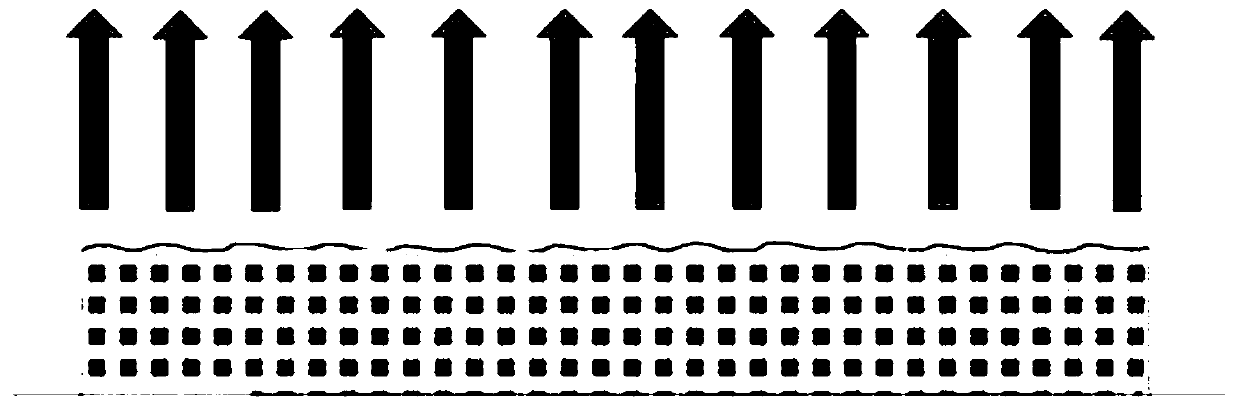

Micro combustor with heat pipes embedded in wall face

InactiveCN106545854AImprove longitudinal thermal conductivityIncrease heat transfer rateIndirect heat exchangersGaseous fuel burnerProcess engineeringChemical energy

The invention belongs to the technical field of micro thermophotovoltaic systems and particularly relates to a micro device, namely a micro combustor which can convert chemical energy of fuel combustion into electric energy, in particular to a micro combustor with heat pipes embedded in the wall face. The structure of the micro combustor is improved based on the micro-scale premixed combustion technology and the micro heat pipe technology, a series of micro heat pipes are additionally arranged in the wall face of the combustor, and the temperature uniformity of the wall face and the overall performance of the micro combustor are improved.

Owner:JIANGSU UNIV

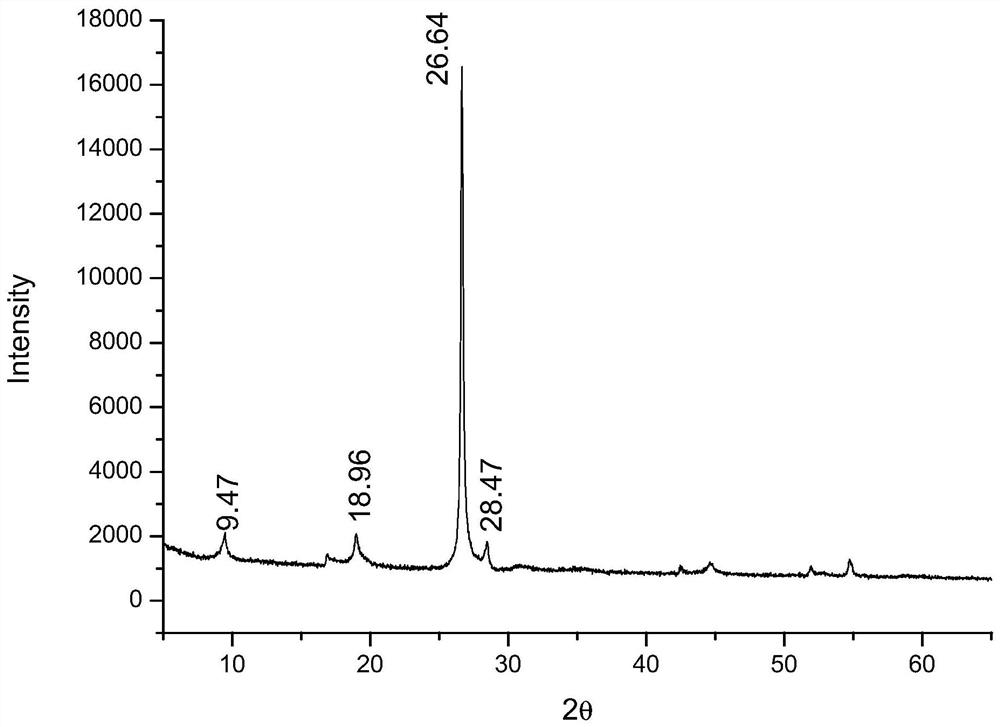

Radiation heat dissipating coating and preparation method thereof

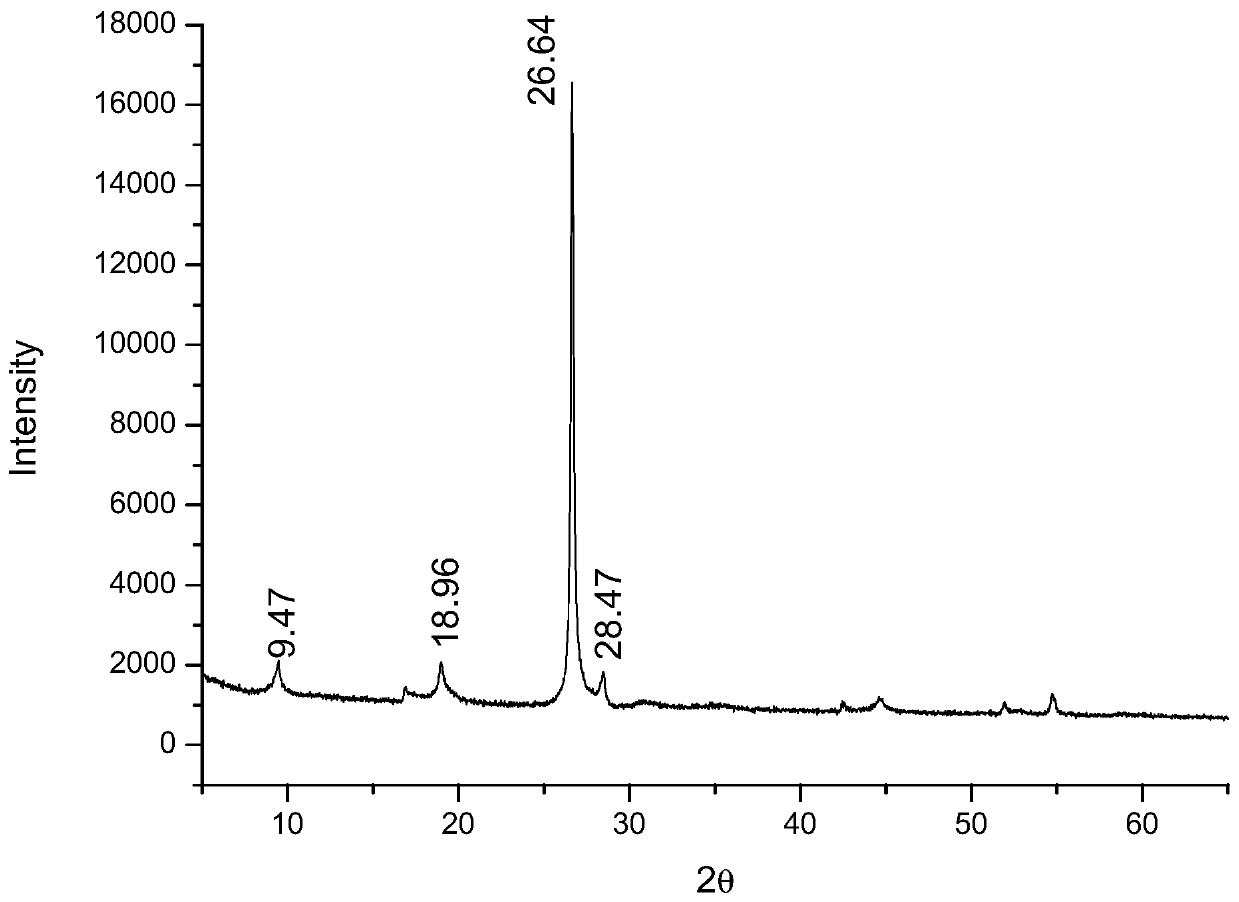

The invention relates to a radiation heat dissipating coating and a preparation method thereof. The radiation heat dissipating coating is composed of the following components in parts by mass: 100 parts of solvent, 2-20 parts of graphene crystallites, 48-200 parts of epoxy resin, 0.5-5 parts of dispersing agent, 0.5-5 parts of antifoaming agent, 2-20 parts of curing agent, and 2-10 parts of auxiliary agent, wherein the auxiliary agent is one or a mixture of two of diatomaceous earth and white carbon black. The heat dissipating coating provided by the invention has extremely excellent thermal conductivity, and the physical and chemical properties of a film formed by solidifying of the coating, such as hardness, adhesion, salt spray resistance, acid and alkali resistance and water resistance, are good, the heat conduction efficiency of electronic components can be significantly improved, and the market prospects are broad.

Owner:广州埃烯特种涂料科技有限公司

A kind of graphite composite heat sink and preparation method thereof

ActiveCN111823664BMaintain thermal advantageImprove longitudinal thermal conductivityLamination ancillary operationsLaminationMetal coatingAdhesive

Owner:SHENZHEN HANKE NEW MATERIAL TECH CO LTD

Preparation method of diamond-loaded graphene thermal interface material for heat dissipation of electronic device

The invention discloses a preparation method of a diamond-loaded graphene thermal interface material for heat dissipation of an electronic device, and relates to a heat conduction material. The graphene sheets are subjected to ultrasonic treatment in absolute ethyl alcohol, and diamond powder and the graphene solution subjected to ultrasonic treatment are mixed and subjected to ultrasonic treatment; performing suction filtration to obtain a suction filtration product, taking down, performing natural air drying at room temperature, and performing high-temperature annealing treatment; soaking the product in absolute ethyl alcohol containing a coupling agent, taking out, and air-drying at room temperature to obtain a heat-conducting framework; the preparation method comprises the following steps: mixing epoxy resin with a catalyst neodymium acetylacetonate (III) hydrate, mixing with a curing agent methylhexahydrophthalic anhydride, and stirring and mixing at room temperature to obtain a mixed solution; soaking the heat-conducting framework into the mixed solution, and removing bubbles in a vacuum oven; and performing two-step treatment in a common drying oven to obtain the graphene thermal interface material. The method is low in cost, simple in process, capable of meeting different use requirements, capable of being produced on a large scale and good in repeatability. The high longitudinal thermal conductivity, the high isotropic thermal conductivity, the shape and the size can be dynamically adjusted according to the device structure.

Owner:XIAMEN UNIV

Oriented assembled graphene, graphene-carbon nanotube composite heat conduction film and preparation method thereof

The invention relates to a method for preparing oriented assembled graphene, which comprises: mixing an aqueous solution of graphene oxide and a water-soluble metal salt, then slowly cooling down until water molecules crystallize into ice, and then freeze-drying to obtain oriented Graphene oxide is assembled, and after reduction, oriented assembled graphene loaded with metal nanoparticles is obtained. The oriented assembled graphene has a three-dimensional layered structure in which layers are arranged in parallel, and interlayer gaps exist between the layers, and metal nanoparticles are riveted in the three-dimensional layered structure of the oriented assembled graphene. The present application also relates to directionally assembled graphene prepared by the method described above. The present application also relates to a graphene-carbon nanotube composite heat-conducting film prepared by using the above-mentioned directional assembled graphene and a preparation method thereof. The composite thermal conductive film described in this paper has the advantages of low cost, high phase orientation of graphene, ultra-high thermal conductivity, and controllable thickness of ultra-high flexibility products. The vertical thermal conductivity can reach up to about 100W / (m·K).

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

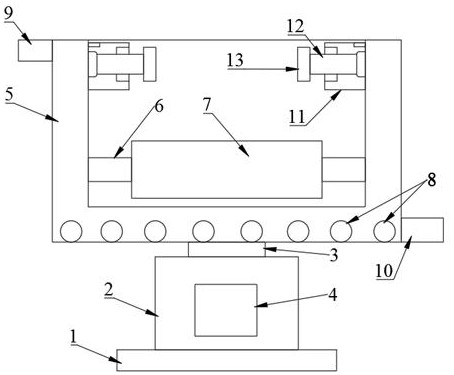

A dual-axis temperature control turntable and its temperature control system

ActiveCN112548959BImprove longitudinal thermal conductivityReduce churnWork benchesTemperature control using electric meansTemperature controlEngineering

The invention discloses a two-axis temperature control turntable, which comprises a base, a turntable is arranged above the base, a constant temperature box is installed above the turntable through a rotating shaft, a motor is arranged inside the turntable, a controller is installed outside the turntable; Both the wall and the bottom plate are interconnected hollow structures. The left and right inner walls of the incubator are equipped with shafts. The shafts are hollow tubular structures. An operating platform is installed on the rod, and a temperature sensor is plugged into the inner cavity of the side wall of the thermostatic box; a heating pipe is also provided in the inner cavity of the bottom plate of the thermostatic box, and a water inlet pipe and a water outlet pipe are also provided on the side wall of the thermostatic box. The invention optimizes and improves the material of the operating table, so that the longitudinal heat conduction performance of the operating table is better, heat loss is reduced, the temperature adjustment speed is fast, the constant temperature control time is long, and the use effect is optimized significantly.

Owner:九江如洋精密科技有限公司

A preparation method of high thermal conductivity graphite airgel-based composite thermal interface material

ActiveCN112708152BEffective distributionSolve the bottleneck problem of heat dissipationModifications by conduction heat transferFreeze-dryingGraphite

The invention discloses a preparation method of a graphite airgel-based composite thermal interface material with high thermal conductivity, relating to the thermal interface material. The method comprises the following steps: adding ascorbic acid into deionized water, stirring to obtain a uniform ascorbic acid solution; stirring and adding GO aqueous solution, transferring the obtained mixed solution to the lining of the reaction kettle, sealing it and putting it into a stainless steel shell, and placing it in a blast drying oven Reaction; the reaction product is transferred from the reactor lining to other containers, and washed repeatedly with deionized and ethanol; the cleaned sample is frozen, and then transferred to a freeze dryer for drying; the sample is placed in a mold, and the sample is compressed with a certain pressure , and then pour the prepared polymer solution into the mold; place it in a vacuum drying oven to dry; the dried sample is demolded from the mold to obtain a high thermal conductivity graphite airgel-based composite thermal interface material. With high longitudinal thermal conductivity, good mechanical properties, self-supporting and easy storage, it is expected to solve the bottleneck problem of heat dissipation in electronic products.

Owner:XIAMEN UNIV

Preparation method of anisotropic composite material for spaceborne radar antenna panel

Owner:HARBIN XIANGKE NEW MATERIAL

A flexible circuit board and mobile terminal

ActiveCN107484327BImprove longitudinal thermal conductivityCircuit thermal detailsCircuit thermal arrangementsFlexible circuitsEngineering

The invention provides a flexible circuit board and a mobile terminal. The flexible circuit board comprises at least one flexible circuit layer. Each flexible circuit layer includes an insulated substrate; a first conductive plate covers the first surface of the insulated substrate; and a first line is arranged on the first conductive plate. A first conduction slot is formed at the position, corresponding to the first line, of the first conductive plate and penetrates the first conductive plate in a thickness direction of the first conductive plate. A second conduction slot is formed at the position, corresponding to the first conduction slot, of the insulated substrate; the second conduction slot and the first conduction slot are communicated; and the second conduction slot penetrates the insulated substrate in the thickness direction of the insulated substrate. And the first conduction slot and the second conduction slot are filled with conducting media. According to the flexible circuit board provided by the invention, the conduction slots are formed in the insulated substrate and are filled with the conducting media, so that the heat generated by the line of the flexible circuit board is transmitted rapidly and vertically by the conducting media. Therefore, the vertical heat conductivity coefficient of the flexible circuit board is increased.

Owner:VIVO MOBILE COMM CO LTD

A kind of graphene heat dissipation coating and its preparation method and application

ActiveCN105273540BSolve the problem of heat conduction and heat dissipationImprove thermal conductivityEpoxy resin coatingsPolyester coatingsGraphene coatingPolymer resin

The invention discloses a graphene heat dissipation coating, which comprises the following components in parts by weight: polymer resin: 40-80 parts; graphene: 5-15 parts; one-dimensional carbon nanomaterial: 1-8 parts; heat conduction Metal powder: 1-8 parts; Dispersant: 0.5-5 parts; Defoamer: 0.5-5 parts; Inert solvent: 100-200 parts; The heat-conducting metal powder is at least selected from silver powder, copper powder and aluminum powder One, and the particle size is 1‑20 μm, the above-mentioned coating has good heat dissipation and heat conduction function. The invention also discloses the preparation method of the graphene heat-dissipating coating, which mainly includes stirring, grinding and remixing processes, and has simple operation and low cost. The above-mentioned graphene heat dissipation coating is mainly used in the heat dissipation of daily electronic products because of its good heat conduction and heat dissipation functions, and can also be used in aerospace electronic devices with higher requirements.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

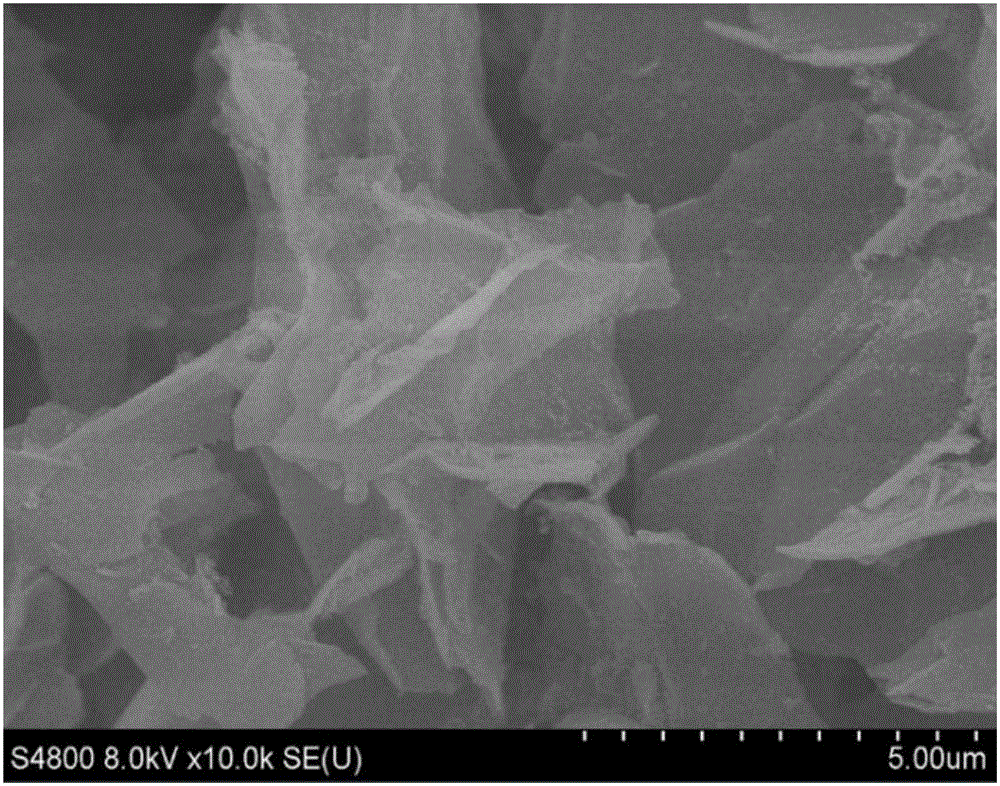

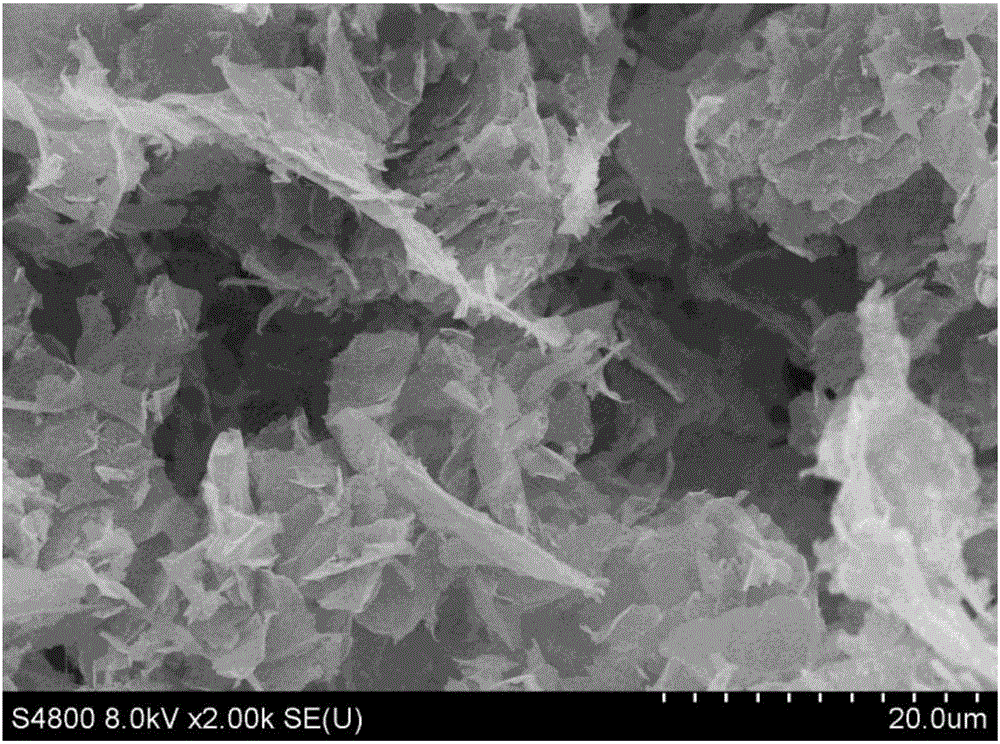

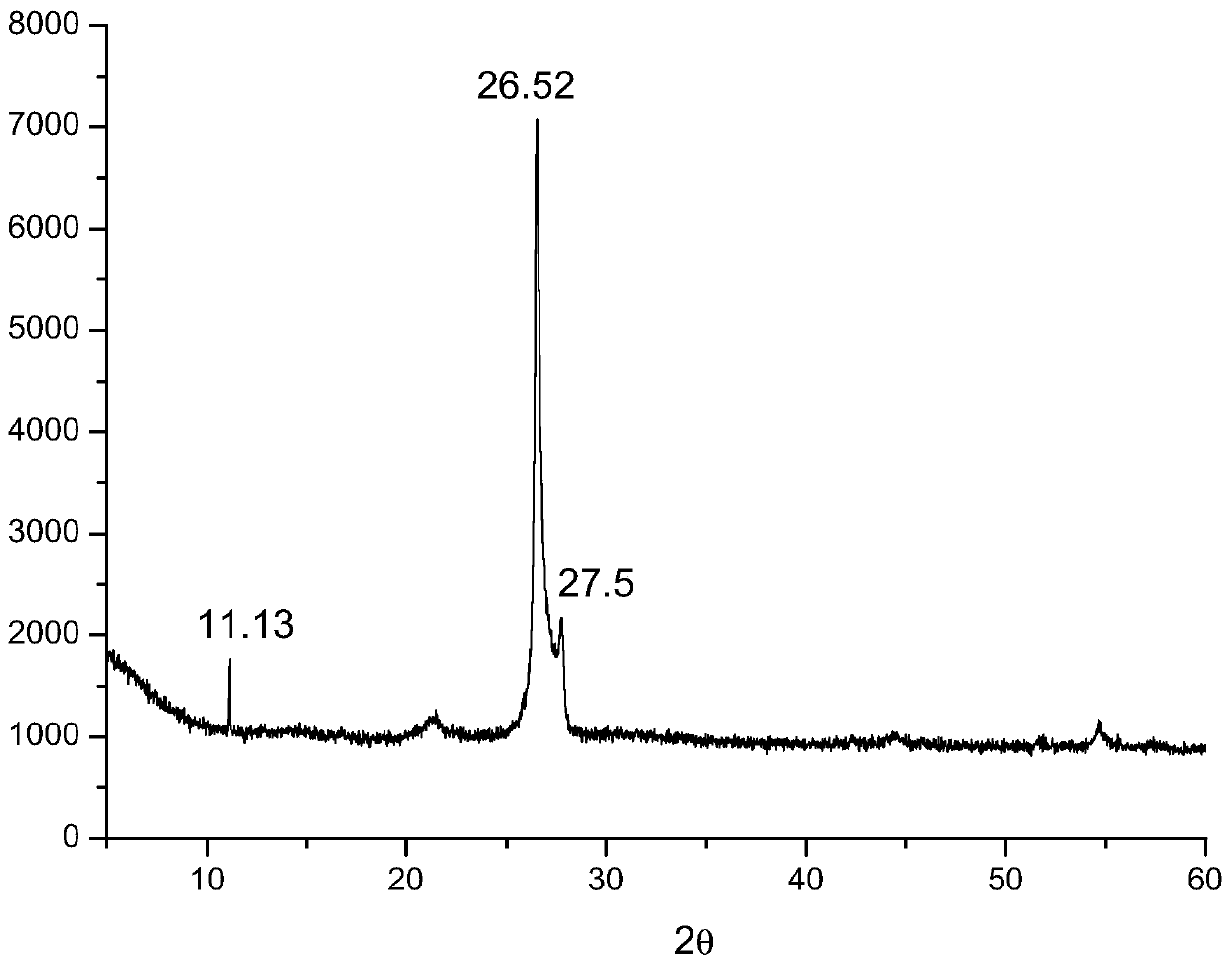

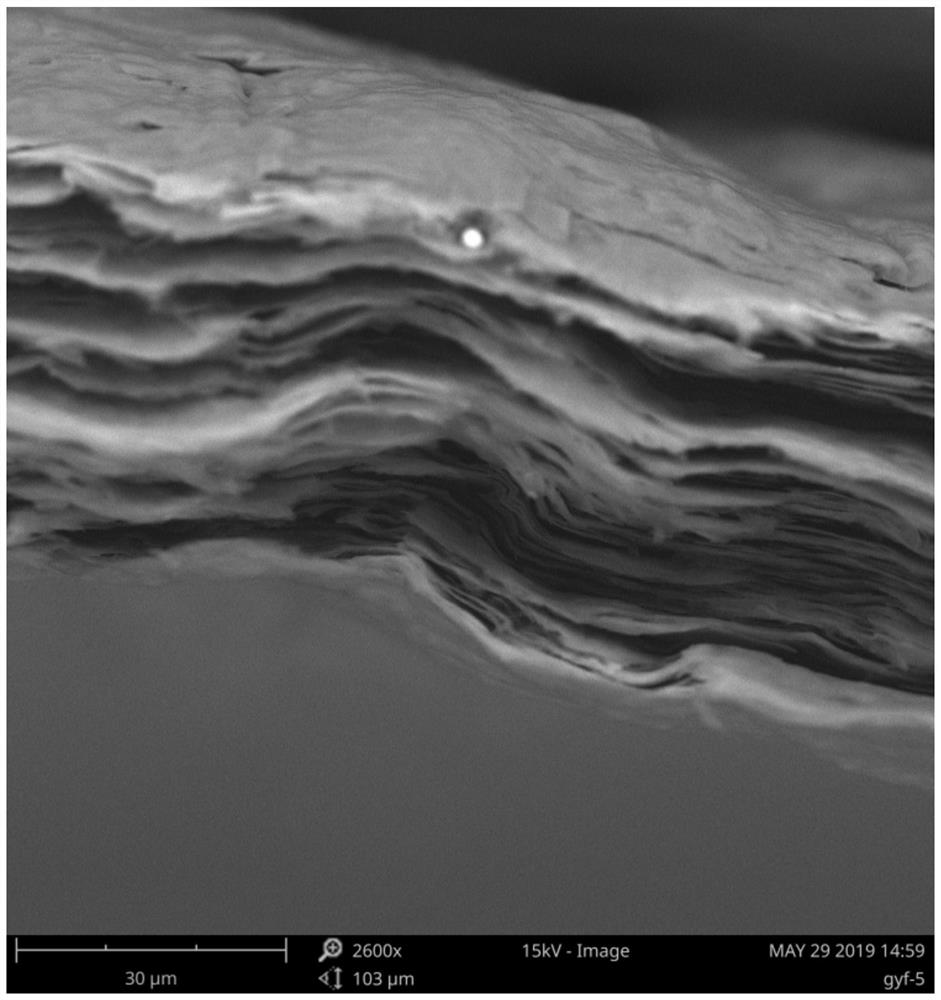

A preparation process of graphene oxide three-dimensional self-assembled sheet

ActiveCN113121233BAchieving three-dimensional self-assemblyFast curingGrapheneOxide compositePhysical chemistry

The invention relates to the technical field of graphene, and relates to a preparation process of a graphene oxide three-dimensional self-assembled plate, comprising the following steps: (1) using hummers to prepare a graphene oxide filter cake; (2) adding deionized water so that its solid content is 1%‑5%, adjust the pH value to 3.0‑4.0; (3) Add urea-formaldehyde resin with a low degree of polymerization to make a graphene oxide composite slurry; (4) Coat the graphene oxide composite slurry on the substrate ;(5) at 50‑70 o Dry at C temperature; (6) Laminate 5‑7 sheets of graphene oxide film (7) at a vacuum degree of ‑60Kpa to ‑100Kpa and a temperature of 100 o C‑200 o Under the condition of C, pressurize at 1‑5MPa, let it stand for 0.5‑1h; (8) under the condition of argon, pressurize at 5‑10MPa, and raise the temperature to 800 o C‑1200 o C, stand still for 1‑2h; (9) in argon state, heat up to 2000‑2500 oC , stand still for 2-3h, complete the graphitization treatment, and make a graphene plate; the invention is simple and easy to implement, and has high practicability.

Owner:GUANGDONG MORION NANOTECHNOLOGY CO LTD

Thin-layer graphene/metal composite heat-conducting film material and preparation method thereof, preparation method of metal salt intercalated graphene, and electronic device

ActiveCN110740623BImprove the problem of low thermal conductivityThin layerGrapheneModifications by conduction heat transferHeat conductingGraphene flake

The invention relates to the field of graphene materials, in particular to a thin-layer graphene / metal composite heat conducting film material and a preparation method thereof, a preparation method ofmetal salt intercalated graphene and an electronic device. The method comprises the following steps: placing the sheet graphene and the heavy metal salt in a sealed environment, controlling the air pressure to be 0.05-0.2 atmosphere and heating and reacting; then forming a slurry; manufacturing the slurry into a heat conducting film and then graphitizing the heat conducting film; low air pressuretreatment is adopted in the intercalation process so that intercalation only exists at the edge of graphene and there is no intercalation inside graphene; the obtained graphene heat conducting film has metal intercalation in the vertical direction of the graphene sheet layer and the metal salt ions are reduced by graphite to form metal-carbon alloy after high temperature alloying and graphitization treatment and the graphene sheet layer is lapped up, wherein the existence of the metal-carbon alloy can improve the vertical thermal conductivity of the graphene thermal conducting film.

Owner:严帆

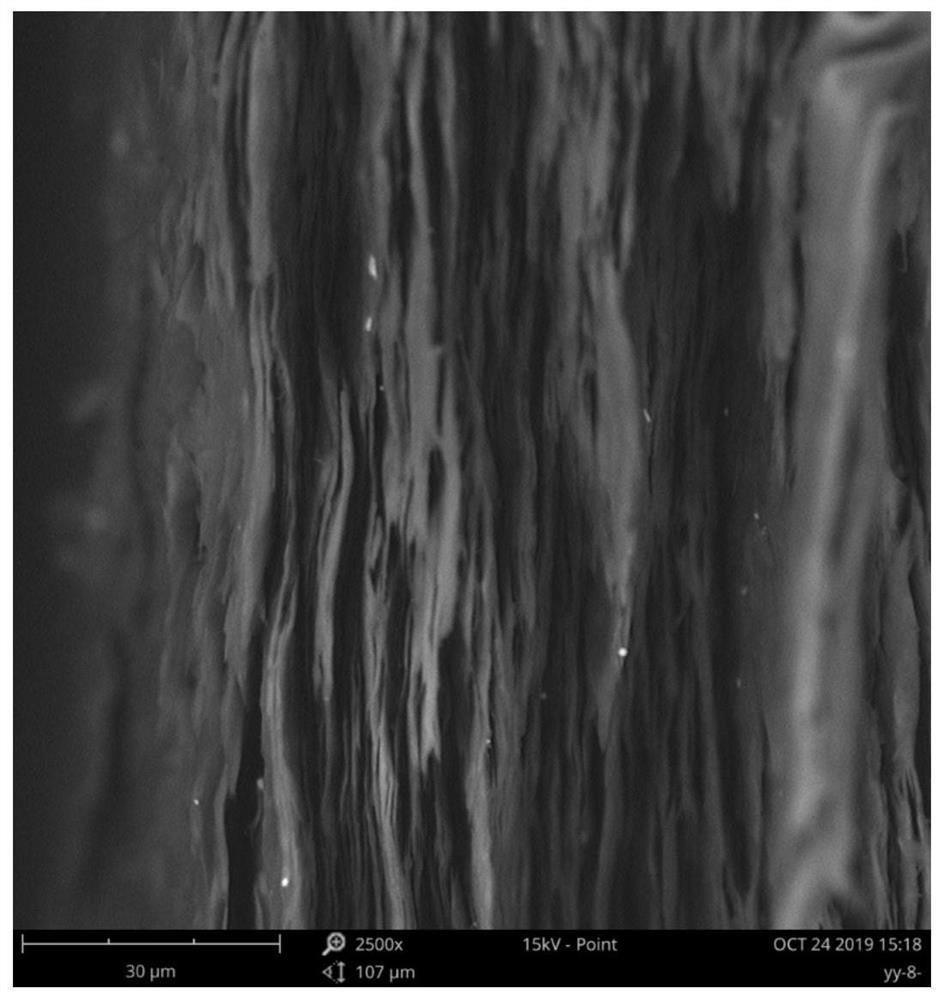

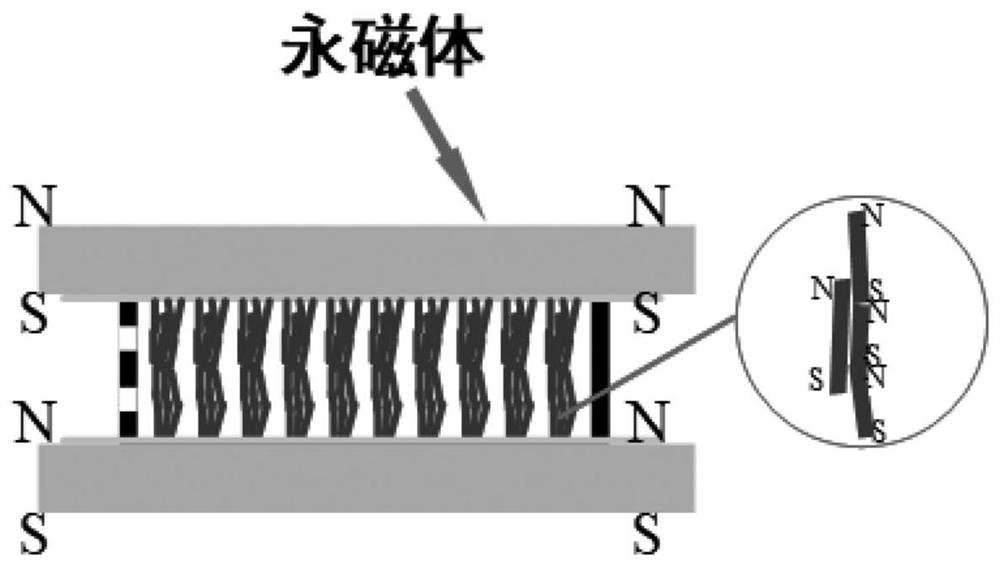

A kind of preparation method and product of directional interconnected high thermal conductivity interface material

ActiveCN112976438BStrong orientationLower interface thermal resistancePolymer sciencePolymer chemistry

The invention belongs to the technical field of polymer composite materials, and discloses a preparation method and product of a directional interconnected high thermal conductivity interface material. The method includes the following steps: S1 adding filler particles into a mold, placing the mold in a permanent magnetic field, and applying vibration to the mold, so that the filler particles are automatically aligned and arranged in the magnetic field under vibration , forming an array of filling particles; S2 maintaining the permanent magnetic field, injecting thermosetting polymer colloid into the mold, and vacuuming the mold to remove the air therein, so that the thermosetting polymer colloid is filled into the filling particle array In the gap, the temperature rises and solidifies, so as to obtain the desired directional interconnected high thermal conductivity interface material. The present application also discloses the product obtained by the above preparation method. The present invention has excellent thermal conductivity, good mechanical strength and processability.

Owner:武汉华兴志远科技有限公司

A kind of graphene-based thermal interface material and preparation method thereof

ActiveCN106633916BGood dispersionQuick exportHeat-exchange elementsHexagonal boron nitrideHeat conducting

The invention provides a preparation method for a graphene based heat-conducting interface material. The preparation method comprises the following steps: A) mixing a graphene material, vinyl silicone rubber, hexagonal boron nitride, flake graphite, hydroxy-terminated silicone oil, vinyl silicone oil and a first silane coupling agent, and carrying out stirring so as to obtain a rubber material, wherein the graphene material is one or more selected from the group consisting of graphene, graphene / silica composite powder and a graphene / silica composite sheet material; and B) subjecting the rubber material to pull-pressing, rolling and cutting so as to obtain the graphene based heat-conducting interface material.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

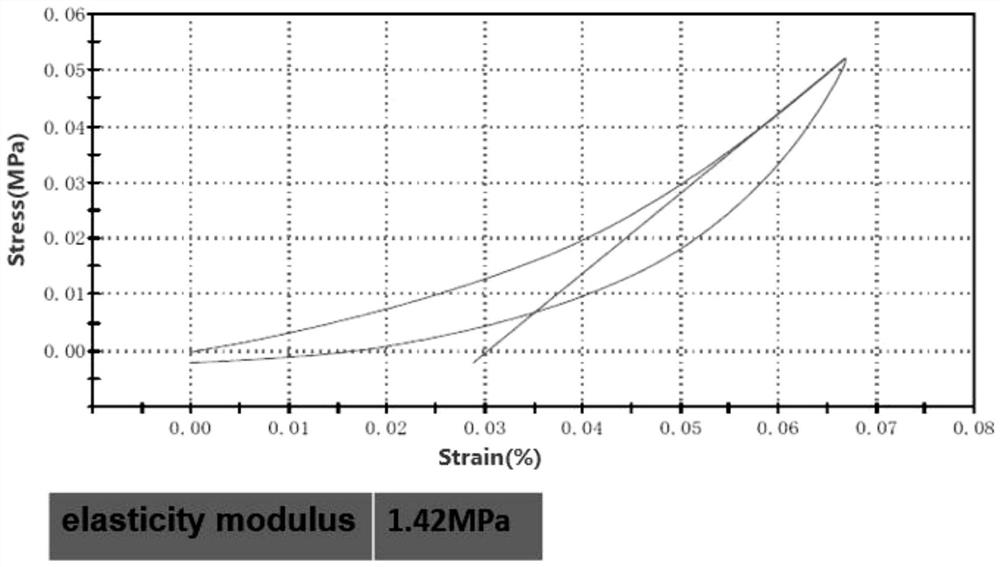

A kind of organosilicon graphite composite thermal interface material and its preparation method and application

ActiveCN109627781BImprove longitudinal thermal conductivityHigh tensile strengthHoneycomb likeHoneycomb structure

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com