Nano interlayer graphene heat dissipation coating and preparation method and application thereof

A technology of layered graphene and heat-dissipating coatings, applied in the field of nano-interlayer graphene heat-dissipating coatings, can solve problems such as poor anti-corrosion performance, slow heat dissipation rate, and lower heating core temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

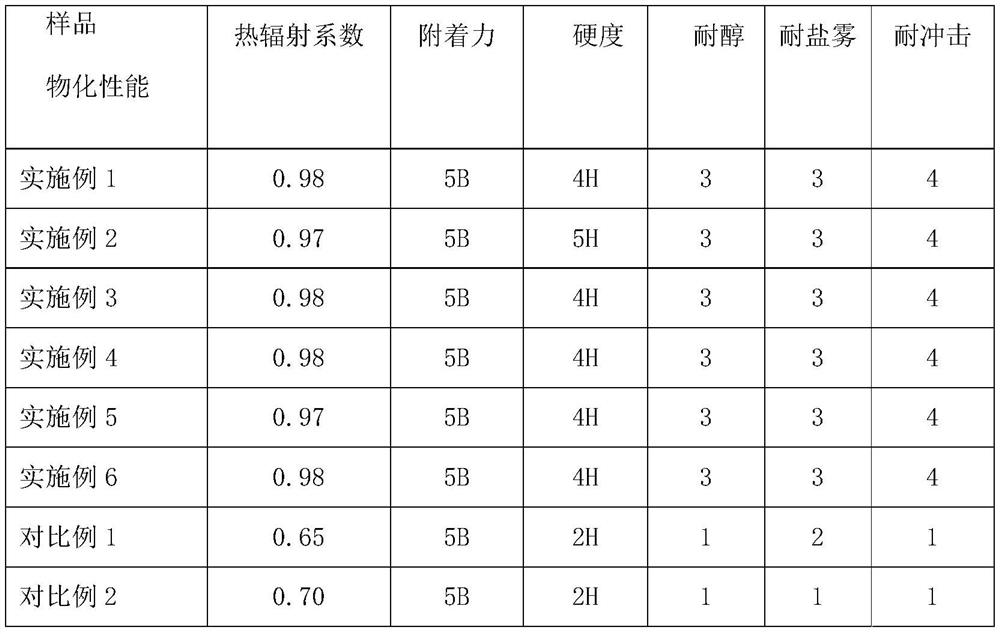

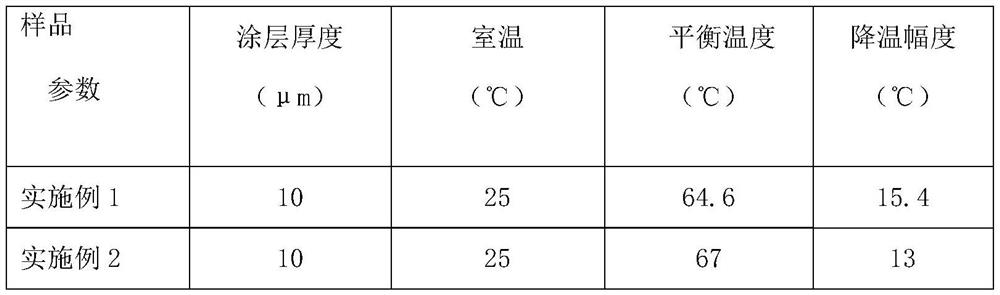

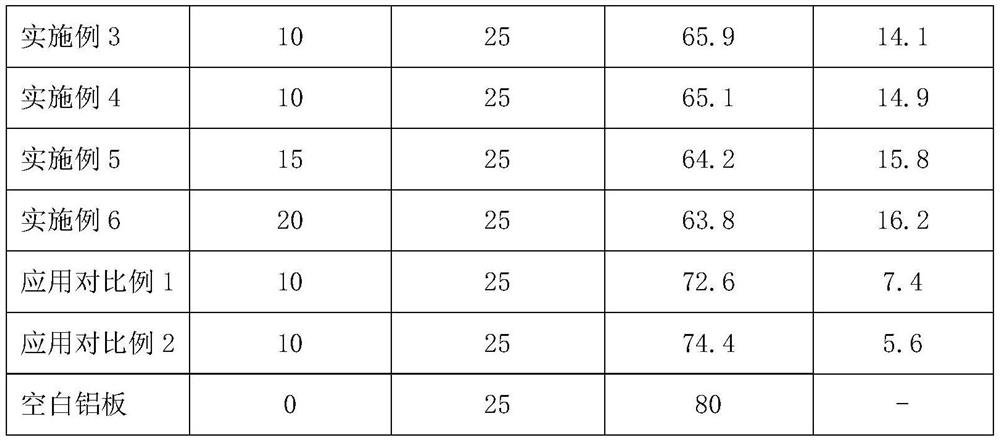

Examples

Embodiment 1

[0053] A kind of preparation method of nano interlayer graphene heat dissipation coating of the present embodiment, described method specifically comprises the following steps:

[0054] (1) 2g graphene is added in 12mL mixed solvent, ultrasonic dispersion 20min, obtain mixed dispersion liquid 1; Then add 0.1g one-dimensional Al to described mixed dispersion liquid 1 2 o 3 Continue to stir the nanowires under ultrasonic conditions until they are uniformly dispersed to obtain a mixed dispersion 2; wherein: the mixed solvent is composed of deionized water and absolute ethanol with a volume ratio of 5:1;

[0055] (2) The mixed dispersion liquid 2 obtained in step (1) is vacuum filtered and freeze-dried to obtain a graphene material-one-dimensional nanowire composite;

[0056] (3) Weigh 2g of the graphene material-one-dimensional nanowire composite obtained in step (2) and add it to 12mL mixed solvent, and ultrasonically disperse it for 20min to obtain mixed dispersion 3; then add...

Embodiment 2

[0063] A kind of preparation method of nano interlayer graphene heat dissipation coating of the present embodiment, described method specifically comprises the following steps:

[0064] (1) Add 2 g of graphene to 10 mL of mixed solvent, ultrasonically disperse for 30 min to obtain mixed dispersion 1; then add 0.2 g of one-dimensional SiC nanowires to the mixed dispersion 1, and continue to stir under ultrasonic conditions until dispersed Uniformly, mixed dispersion 2 is obtained; wherein: the mixed solvent is composed of deionized water and absolute ethanol with a volume ratio of 3:1;

[0065] (2) Filtrating the mixed dispersion 2 obtained in step (1), and then baking at 100° C. for 30 minutes to obtain a graphene material-one-dimensional nanowire composite;

[0066] (3) Weigh 2g of the graphene material-one-dimensional nanowire composite obtained in step (2) and add it to 10mL mixed solvent, and ultrasonically disperse it for 30min to obtain mixed dispersion 3; then add 0.2 ...

Embodiment 3

[0073] A kind of preparation method of nano interlayer graphene heat dissipation coating of the present embodiment, described method specifically comprises the following steps:

[0074] (1) Add 2g graphene to 20mL mixed solvent, ultrasonically disperse for 10min to obtain mixed dispersion 1; then add 0.3g one-dimensional Al to the mixed dispersion 1 2 o 3 Continue to stir the nanowires under ultrasonic conditions until they are uniformly dispersed to obtain a mixed dispersion 2; wherein: the mixed solvent is composed of deionized water and absolute ethanol with a volume ratio of 2:1;

[0075] (2) The mixed dispersion liquid 2 obtained in step (1) is vacuum filtered and freeze-dried to obtain a graphene material-one-dimensional nanowire composite;

[0076] (3) Weigh 2g of the graphene material-one-dimensional nanowire composite obtained in step (2) and add it to 20mL mixed solvent, and ultrasonically disperse it for 10min to obtain mixed dispersion 3; then add 0.3 gZero-dimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com