Directionally assembled graphene, graphene-carbon nano tube composite heat-conducting film and preparation method thereof

A carbon nanotube composite, carbon nanotube technology, applied in the directions of carbon nanotubes, graphene, nanocarbon, etc., can solve the problems of non-adjustable product thickness, high production cost, low thermal conductivity, etc. The effect of low cost, ultra-high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

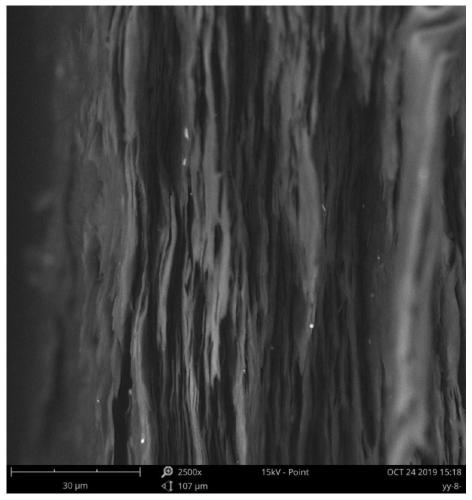

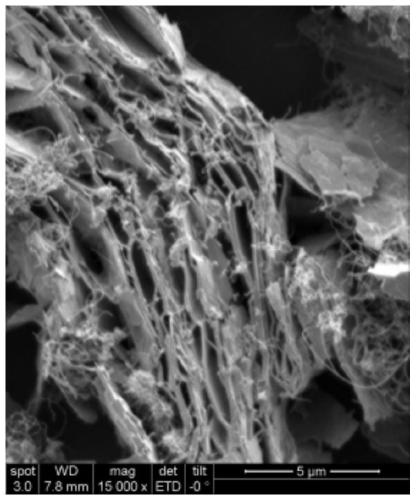

[0062] The three-dimensional space overlapping technology of porous graphene: mix graphene oxide: water mass ratio 1:10 evenly, add copper acetate, the mass ratio of copper acetate and graphene oxide solution is 1:100, and mix evenly. The mixed liquid is cooled slowly until the water molecules crystallize into ice, and then moved to a freeze dryer for freeze-drying. The drying temperature is -50°C and the drying time is 24 hours. By controlling the freezing rate, a three-dimensional layered oxidation with parallel layers can be obtained. Graphene, in which copper is evenly distributed between graphene layers. The three-dimensional layered graphene was reduced in a hydrogen atmosphere, the reduction temperature was 300°C, and the reduction time was 2 hours, to obtain copper nanoparticles@three-dimensional layered graphene. Depend on figure 1 It can be seen that the copper nanoparticles are riveted in the layered graphene, and the distance between graphene layers is about 0.05 ...

Embodiment 2

[0067] The three-dimensional space overlapping technology of porous graphene: mix graphene oxide: water mass ratio 1:20 evenly, add copper acetate, the mass ratio of copper acetate and graphene oxide solution is 1:200, and mix evenly. The mixed liquid is cooled slowly until the water molecules crystallize into ice, and then moved to a freeze dryer for freeze-drying. The drying temperature is -50°C and the drying time is 24 hours. By controlling the freezing rate, a three-dimensional layered oxidation with parallel layers can be obtained. Graphene, in which copper is evenly distributed between graphene layers. The three-dimensional layered graphene is reduced in a hydrogen atmosphere, the reduction temperature is 400 ° C, and the reduction time is 2 hours to obtain copper nanoparticles@three-dimensional layered graphene, in which the copper nanoparticles are riveted in the layered graphene, and the graphene layer The pitch is about 0.1 μm.

[0068] In this embodiment, "slowly ...

Embodiment 3

[0072] The three-dimensional space overlapping technology of porous graphene: mix graphene oxide: water mass ratio 1:10 evenly, add ferric chloride, the mass ratio of ferric chloride and graphene oxide solution is 1:100, and mix evenly. The mixed liquid is cooled slowly until the water molecules crystallize into ice, and then moved to a freeze dryer for freeze-drying. The drying temperature is -50°C and the drying time is 24 hours. By controlling the freezing rate, a three-dimensional layered oxidation with parallel layers can be obtained. Graphene, in which the iron element is evenly distributed between the graphene layers. The three-dimensional layered graphene is reduced in a hydrogen atmosphere, the reduction temperature is 400 ° C, and the reduction time is 2 hours to obtain iron nanoparticles@three-dimensional layered graphene, in which the iron nanoparticles are riveted in the layered graphene, and the graphene layer The pitch is about 0.2 μm.

[0073] In this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com