Thin-layer graphene/metal composite heat-conducting film material and preparation method thereof, preparation method of metal salt intercalated graphene, and electronic device

A thin-layer graphene and metal composite technology, applied in graphene, non-metallic elements, chemical instruments and methods, etc., can solve problems such as low thermal conductivity, and achieve the effect of good environmental protection and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The embodiment of the present application provides a method for preparing a thin-layer graphene / metal composite thermally conductive film material, including:

[0055] Place the sheet graphene and the heavy metal salt in a sealed environment, control the air pressure at 0.05 to 0.2 atmospheres, and heat the reaction until at least part of the heavy metal salt is inserted into the interlayer edge of the sheet graphene to form a metal salt intercalated graphene;

[0056] Mixing metal salt intercalated graphene and dispersant into a solution and then sanding to form a slurry;

[0057] Making the slurry into a thermally conductive film;

[0058] High-temperature alloying and graphitization are carried out on the heat-conducting film, so that the interlayer edges of the graphene sheet form a metal-carbon alloy.

[0059] During the intercalation process, low-pressure treatment is adopted, so that there is only intercalation at the edge of the graphene, and there is no interc...

Embodiment 1

[0119] The present embodiment provides a thin-layer graphene / metal composite heat-conducting film material, which is prepared in the following way:

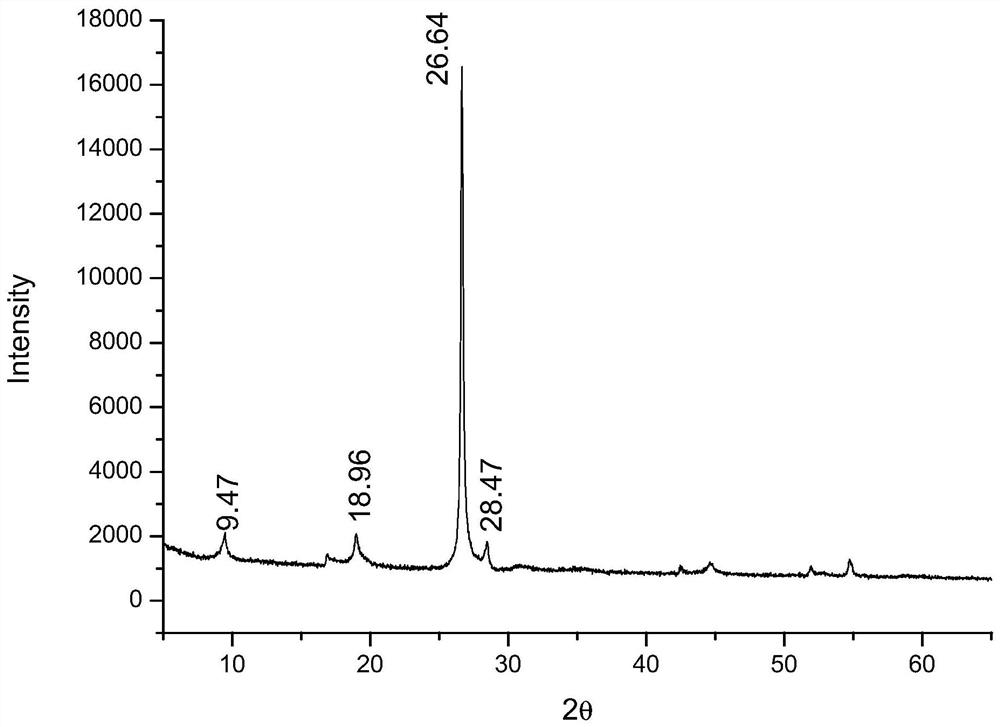

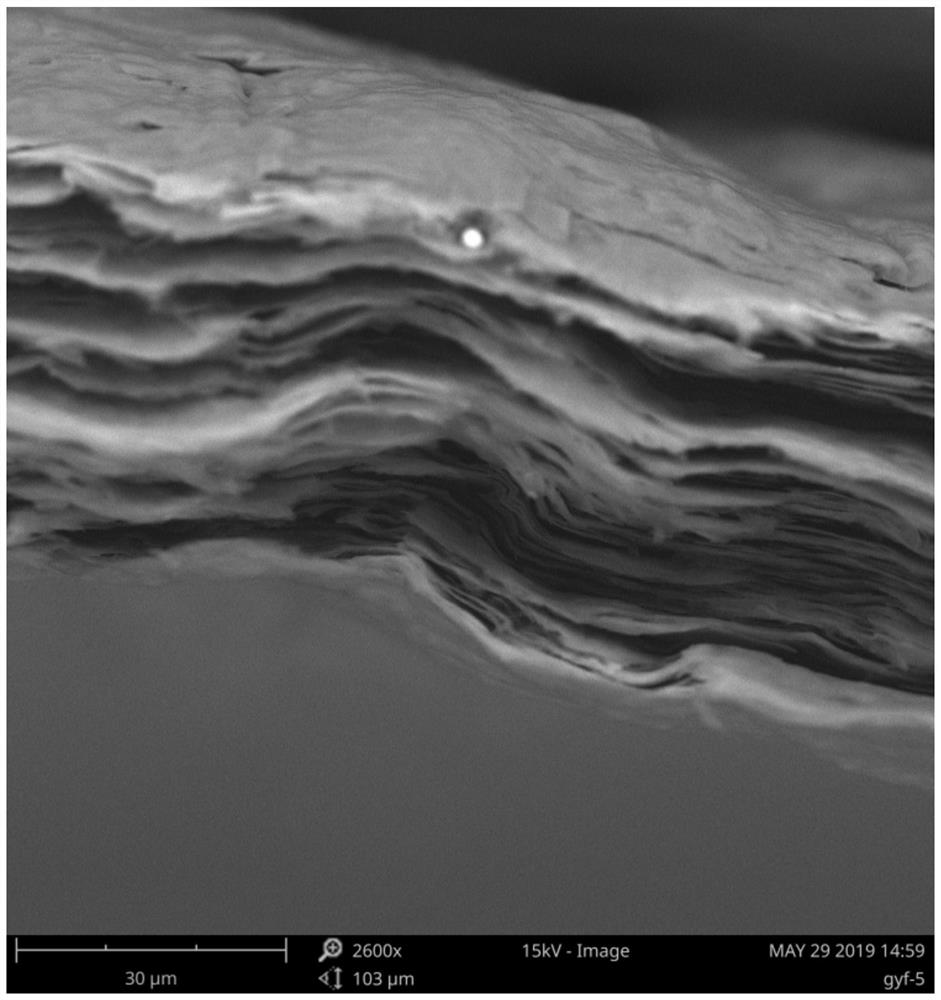

[0120] Put 20 parts of graphene nanopowder with a thickness of 3nm and a sheet size greater than 10 microns and 1 part of anhydrous ferric chloride in a reaction kettle made of quartz, vacuumize to 0.1 atmospheric pressure, and keep it in an airtight state. Reactor is placed in the high-temperature environment of 380 ℃, reacts 15 hours, after being down to room temperature then, open reactor, obtain the graphene nanosheet of edge intercalation ( figure 1 XRD patterns). In parts by mass, after washing and drying 1 part of graphene nanosheets with edge intercalation made with clear water, add 400 parts of deionized water, add 1 part of polyvinylpyrrolidone (PVP) and 1 part of hydroxymethyl Cellulose (CMC) to obtain a mixture, then put the mixture into a sand mill for sand grinding and disperse for 10 hours, take it out and stir it...

Embodiment 2

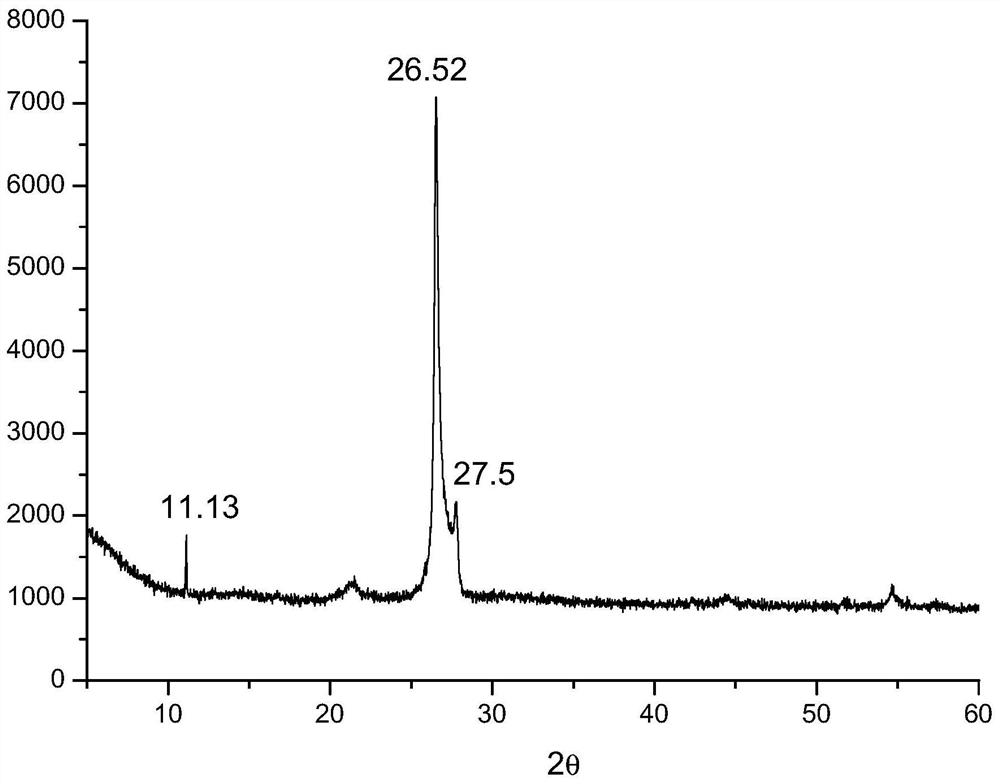

[0122] This embodiment provides a kind of thin-layer graphene / metal composite heat-conducting film material, and its preparation steps are basically the same as embodiment 1, the difference is that the intercalation is changed to copper chloride ( image 3 The XRD spectrum of the graphene nanoplatelet of the edge intercalation of making is shown), vacuumized to 0.05 atmospheric pressure, ratio is 25 parts of graphene nanopowder and 2 parts of cupric chloride powder, reaction temperature is 450 ℃, reaction time 24 hours. The post-stage slurry preparation, coating, high-temperature annealing, calendering, and cutting processes are all the same as in Example 1, and the calendering density reaches 1.95g / cm 3 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com