Micro combustor with heat pipes embedded in wall face

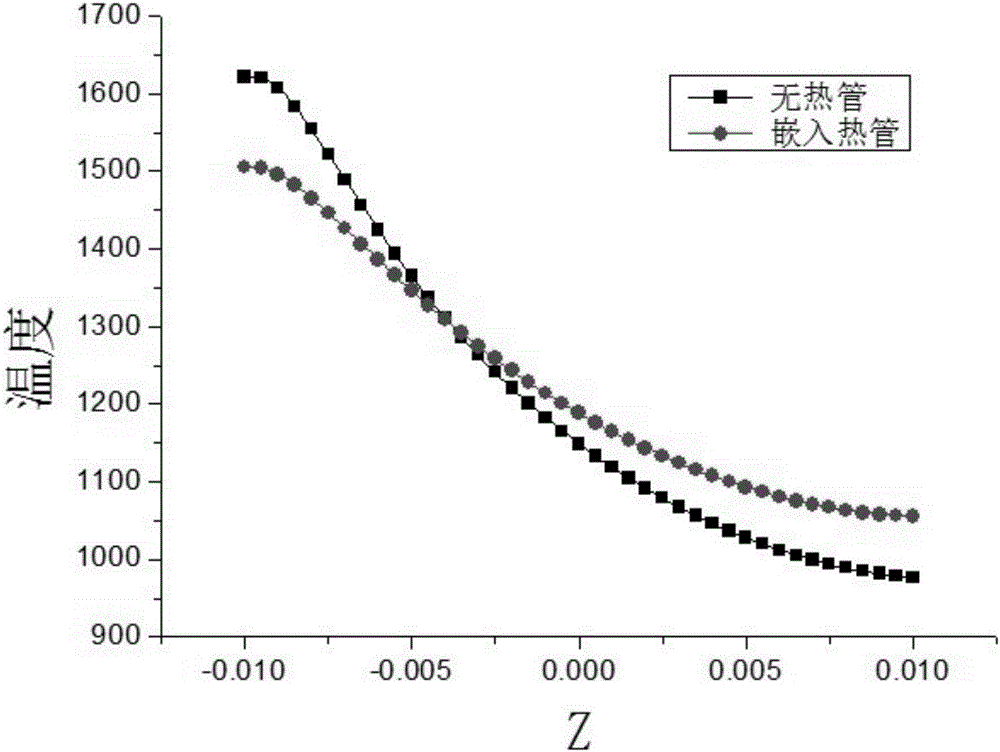

A micro-combustion and burner technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of unstable flame, large radiation wavelength range, and increased heat dissipation rate, so as to improve the temperature uniformity of the wall surface, improve the Longitudinal thermal conductivity, the effect of improving fuel conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

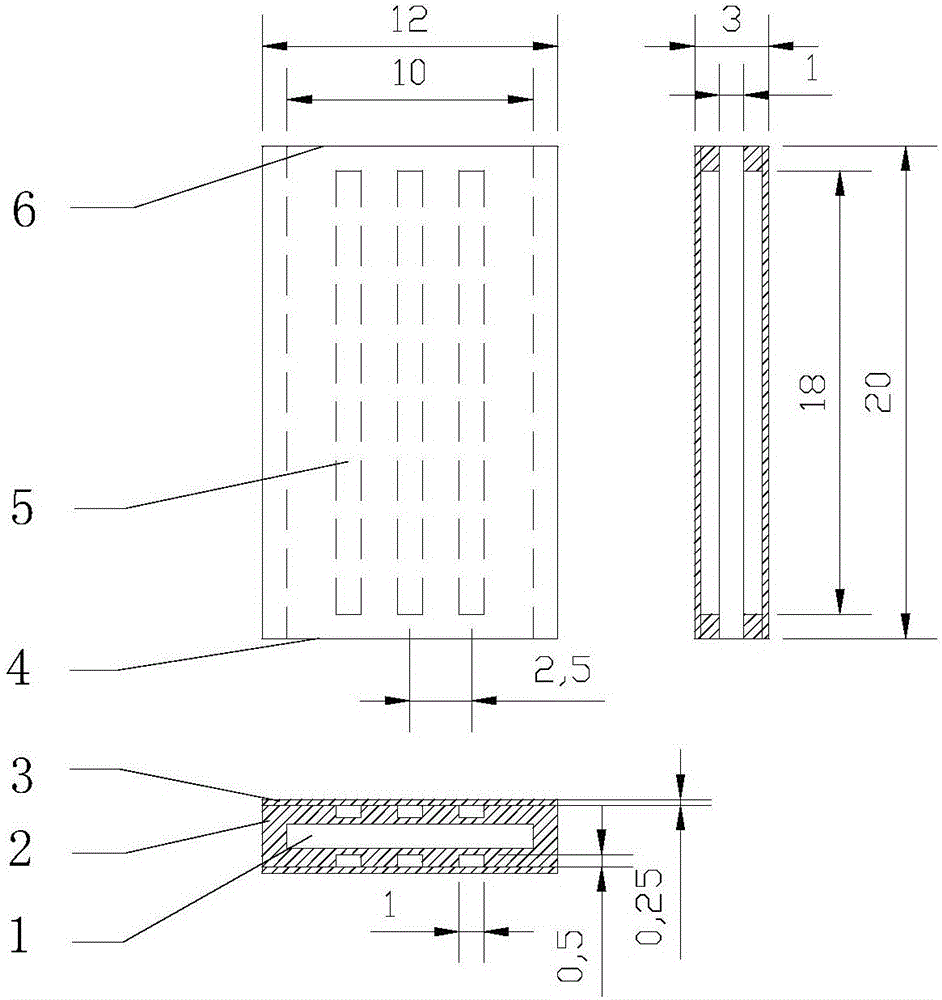

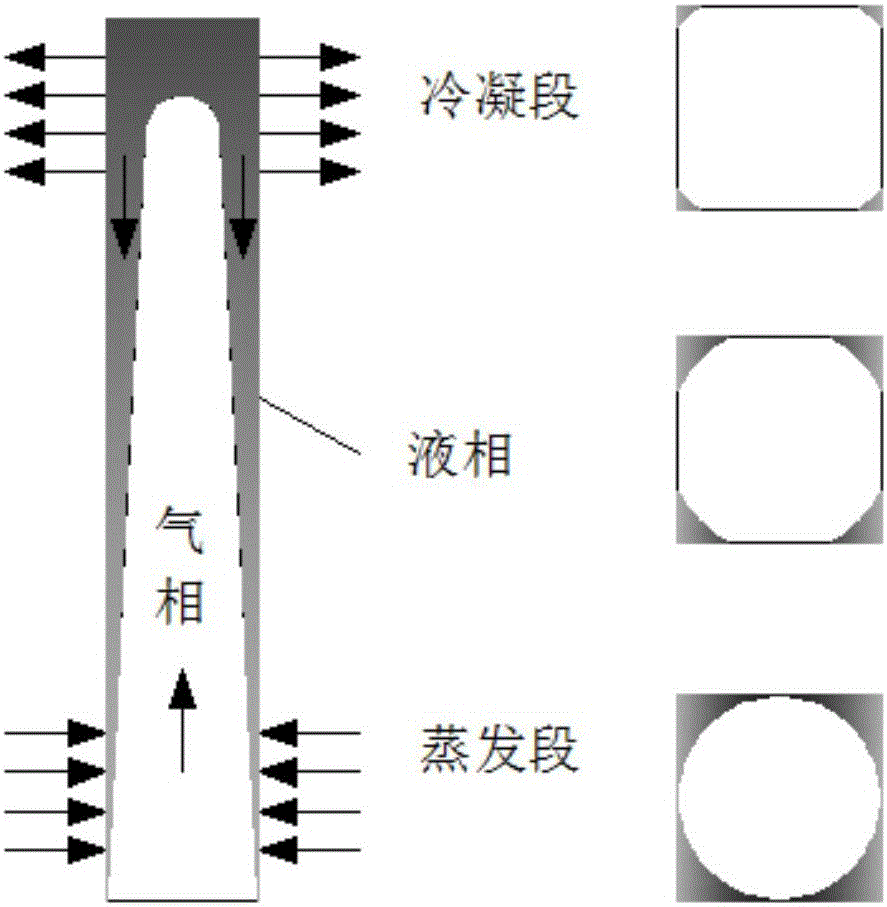

[0018] see figure 1 , the present invention has a flat burner, the fuel gas enters the combustion chamber 1 through the inlet 4, after the fuel gas is burned in the combustion chamber, the tail gas is discharged from the outlet 6, and the surface of the groove 5 is sealed with a SiC cover plate 3 to form a miniature heat pipe, close to the inlet The part is the evaporation section, and the part near the outlet is the condensation section. The liquid sodium potassium alloy absorbs heat and evaporates into a gaseous sodium potassium alloy. It is quickly transmitted from the evaporation section to the condensation section, which makes the wall temperature more uniform, makes the combustion more stable, and expands the combustion limit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com