A kind of preparation method and product of directional interconnected high thermal conductivity interface material

An interface material and high thermal conductivity technology, which is applied in the field of preparation of high thermal conductivity interface materials, can solve the problems of unsuitable filling concentration, complex preparation process, difficult processing, etc., so as to improve the strength and thermal stability, the preparation method is simple, and the vertical direction is improved. The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

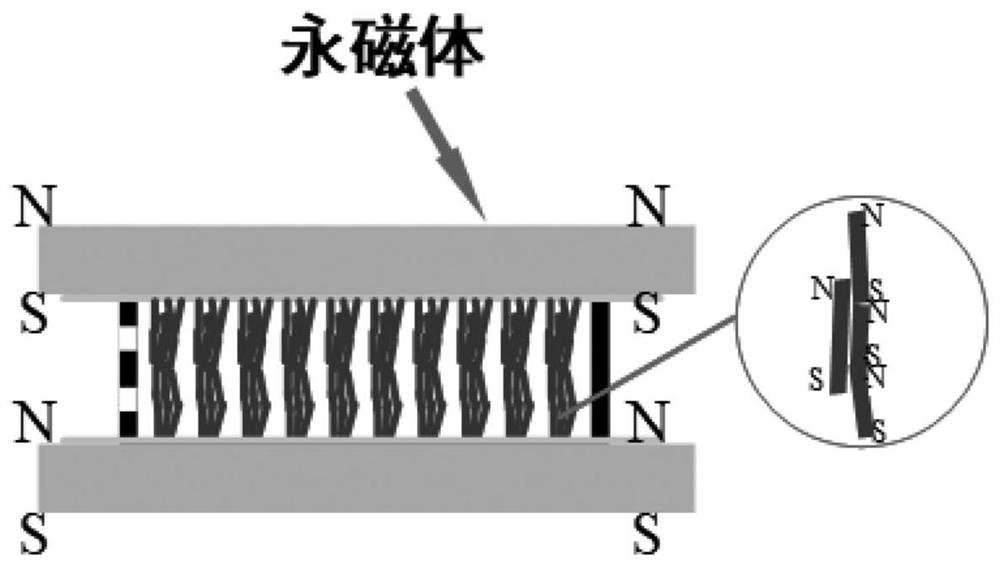

[0026] like figure 1 As shown, a preparation method of the above thermal interface composite material, the preparation method comprises the following steps:

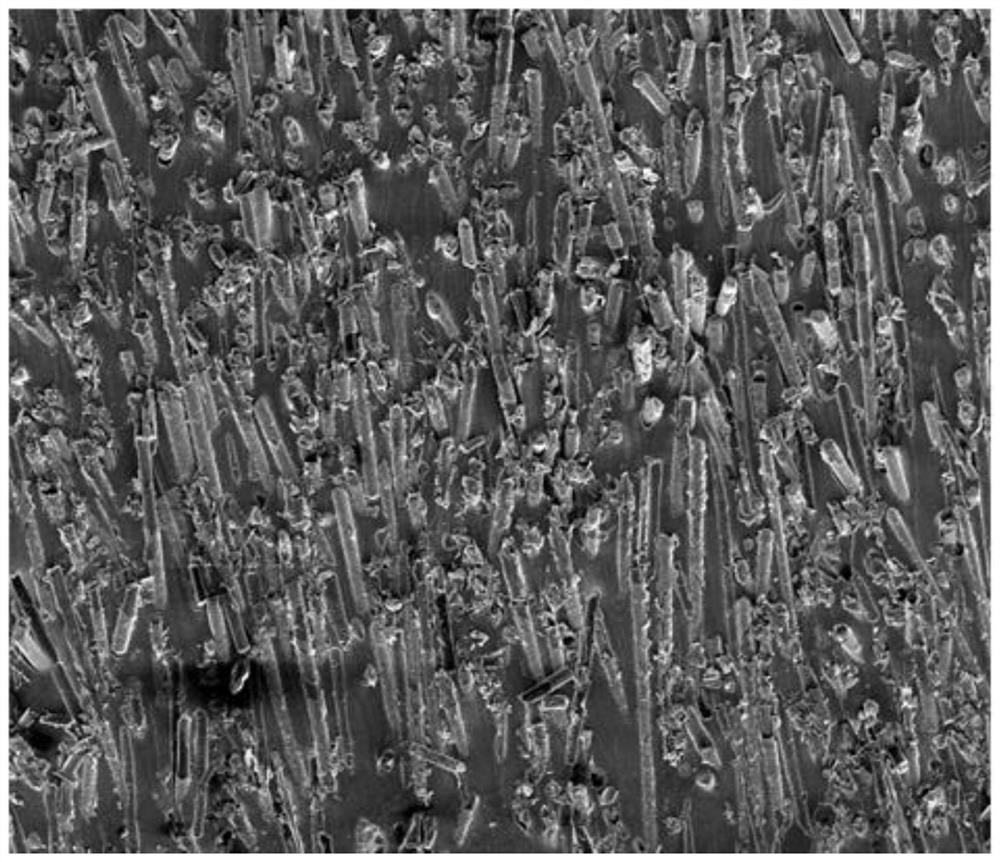

[0027] (1) Preparation of directional interconnected filled particle arrays: The filled particles are placed in a PTFE mold with two small holes on the side, and then the top surface is covered with a glass sheet, on the bottom of the mold and above the glass sheet Place NdFeB permanent magnets with opposite NS poles, and then apply vibration to the mold, so that the filling particles in the mold can be automatically arranged under the action of vibration and magnetic field to form a filling particle array.

[0028] (2) Preparation of thermal interface material: The colloid of the polymer matrix is added to the mold through the two holes on the side of the mold, and the whole device is placed in a vacuum heating box after filling. The mold is repeatedly evacuated 3-5 times for 15 minutes each time. After the air in th...

Embodiment 1

[0044] This embodiment provides a thermal interface composite material, and the specific preparation method includes the following steps:

[0045] (1) Preparation of directional interconnected nickel-plated carbon fiber arrays: 0.1 g of functionalized nickel-plated carbon fiber A (the precursor is PAN-based carbon fiber, with a nickel mass fraction of 80%) is placed on a polymer with two small holes on the side. In the tetrafluoroethylene mold, the top surface is covered with a 2mm thick glass sheet, and a NdFeB permanent magnet with opposite NS poles is placed on the bottom of the mold and above the glass sheet, and the magnetic field strength is 200mT. Then apply vibration to the mold;

[0046] (2) Preparation of thermal interface material: PDMS colloid is added into the mold through the two holes on the side of the mold. After filling, place the entire device in a vacuum oven. Under the normal temperature environment, the mold placed in the vacuum heating box was repeated...

Embodiment 2

[0049] The difference between this example and Example 1 is that in step (1), the nickel-plated carbon fiber A (precursor is PAN-based carbon fiber, nickel mass fraction is 80%) powder is 0.26g, and the magnetic field strength is 300mT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com