Graphite composite radiating fin and preparation method thereof

A technology of composite heat sink and graphite sheet, which is applied in chemical instruments and methods, modification through conduction heat transfer, cooling/ventilation/heating modification, etc. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

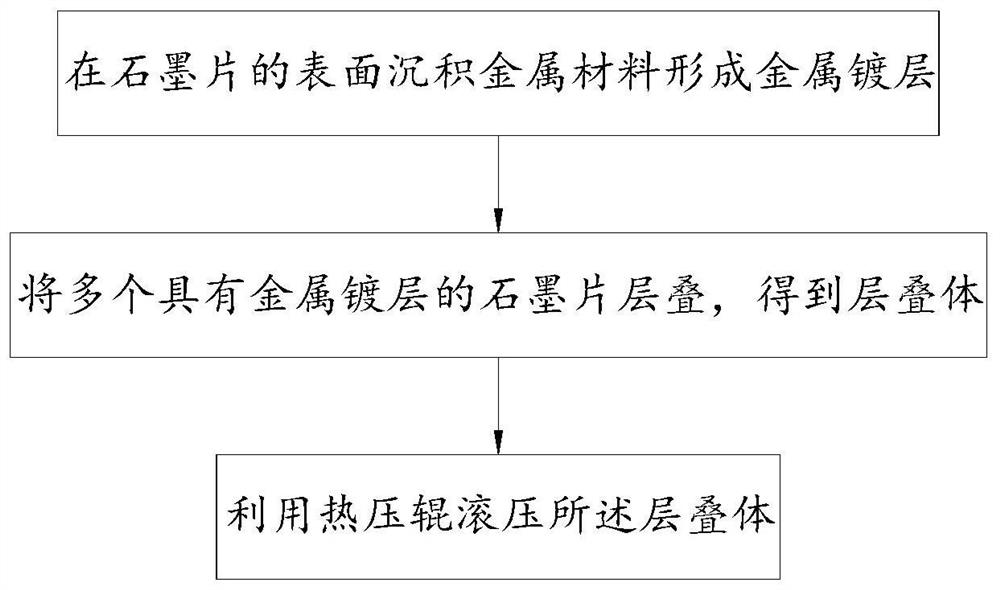

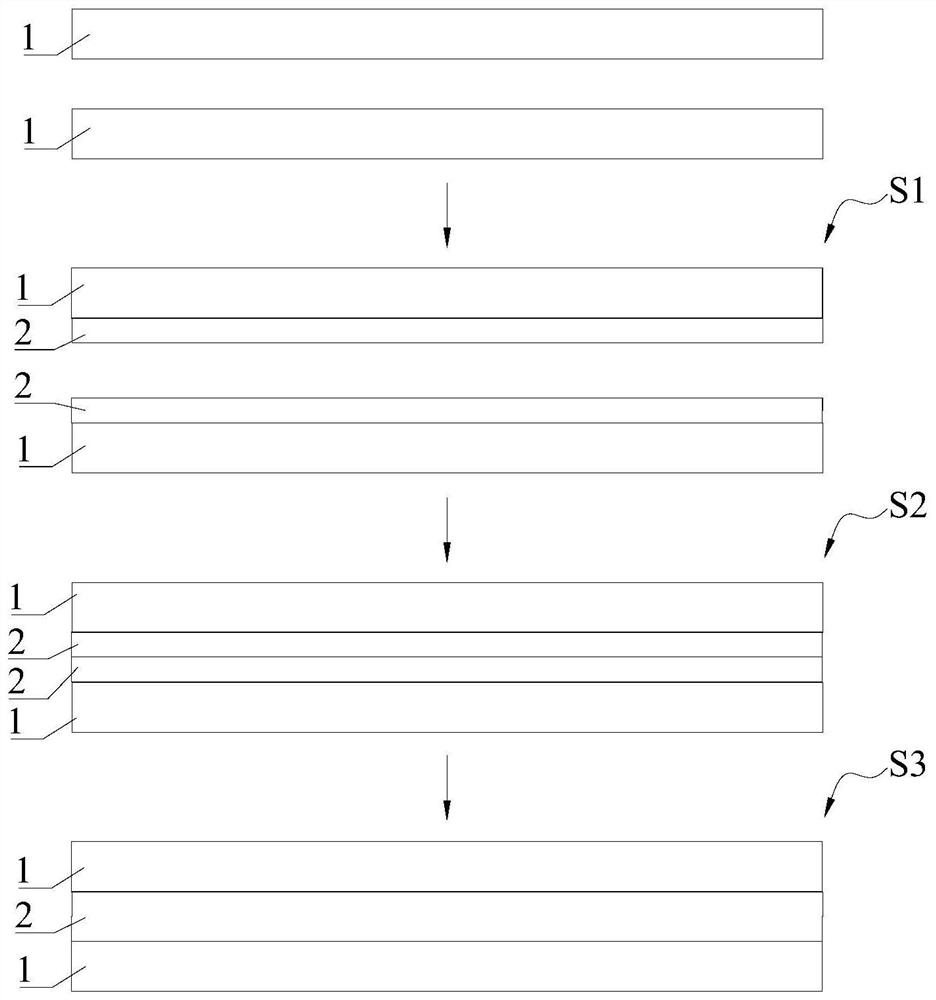

[0028] Please refer to Figure 1 to Figure 5 , a preparation method of a graphite composite heat sink, comprising the steps of,

[0029] Depositing a metal material on the surface of the graphite sheet 1 to form a metal coating 2;

[0030] Stacking a plurality of graphite sheets 1 with a metal coating 2 to obtain a laminate;

[0031] The laminate was rolled with a heated press roll.

[0032] The principle of the present invention is briefly described as follows: when the hot pressing roller works, the heat is transferred to the metal coating between the adjacent two layers of graphite sheets through the graphite sheet, so that the metal coating is melted, and the graphite sheet is applied with pressure at the same time, and the metal to be melted After the coating is solidified, the adjacent two layers of graphite sheets are fixedly connected together. The raw material of the metal coating is metal, and its thermal conductivity is much higher than that of the adhesive, so t...

Embodiment 1

[0051] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is: a graphite composite heat sink, which is not only used for heat dissipation of mobile terminal equipment, such as electronic equipment such as mobile phones and tablet computers, but also for heat dissipation of office equipment such as printers and copiers. Of course, it can also be used For the heat dissipation of other equipment with heat dissipation requirements.

[0052] The preparation method of the graphite composite heat sink is as follows:

[0053] S1. Depositing a metal material with a low melting point and high thermal conductivity on the surface of the graphite sheet 1 by magnetron sputtering to form a metal coating 2. In this embodiment, the metal material with a low melting point and high thermal conductivity is tin;

[0054] S2, stacking a plurality of graphite sheets 1 with a metal coating 2 to obtain a laminate;

[0055] S3. Rolling the laminated body with a hot pressing...

Embodiment 2

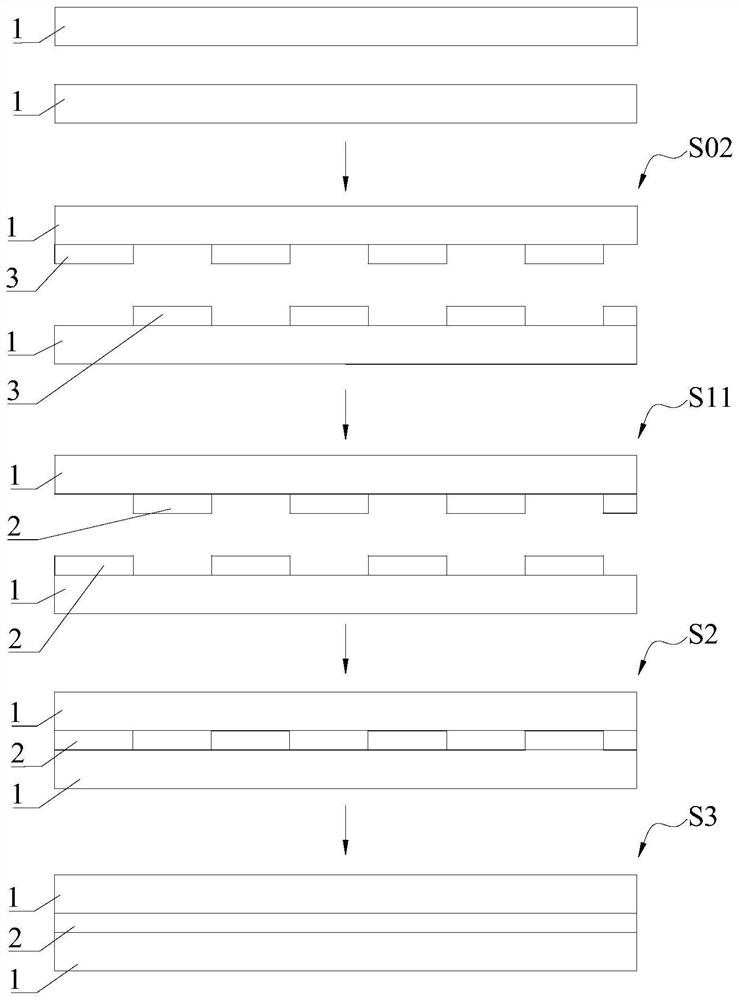

[0063] Please refer to figure 1 and figure 2 , the second embodiment of the present invention is: a graphite composite heat sink, which can be used for heat dissipation of mobile terminal equipment, such as electronic equipment such as mobile phones and tablet computers, and can also be used for heat dissipation of office equipment such as printers and copiers. Of course, it can also be used For the heat dissipation of other equipment with heat dissipation requirements.

[0064] The preparation method of the graphite composite heat sink is as follows:

[0065] S1. Depositing a metal material with a low melting point and high thermal conductivity on the surface of the graphite sheet 1 by evaporation to form a metal coating 2. In this embodiment, the metal material with a low melting point and high thermal conductivity is aluminum;

[0066] S2, stacking a plurality of graphite sheets 1 with a metal coating 2 to obtain a laminate;

[0067] S3. Rolling the laminated body with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com