High-thermal-conductivity composite graphite cooling fin and preparation method thereof

A technology of composite graphite and heat sink, which is applied to chemical instruments and methods, modification through conduction and heat transfer, and other household appliances, etc. It can solve the problem that heat cannot be transferred in time, reduce the thermal conductivity of carbon material layers, and weaken the heat dissipation effect of graphite film, etc. problems, and achieve the effects of low cost, wide range of availability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

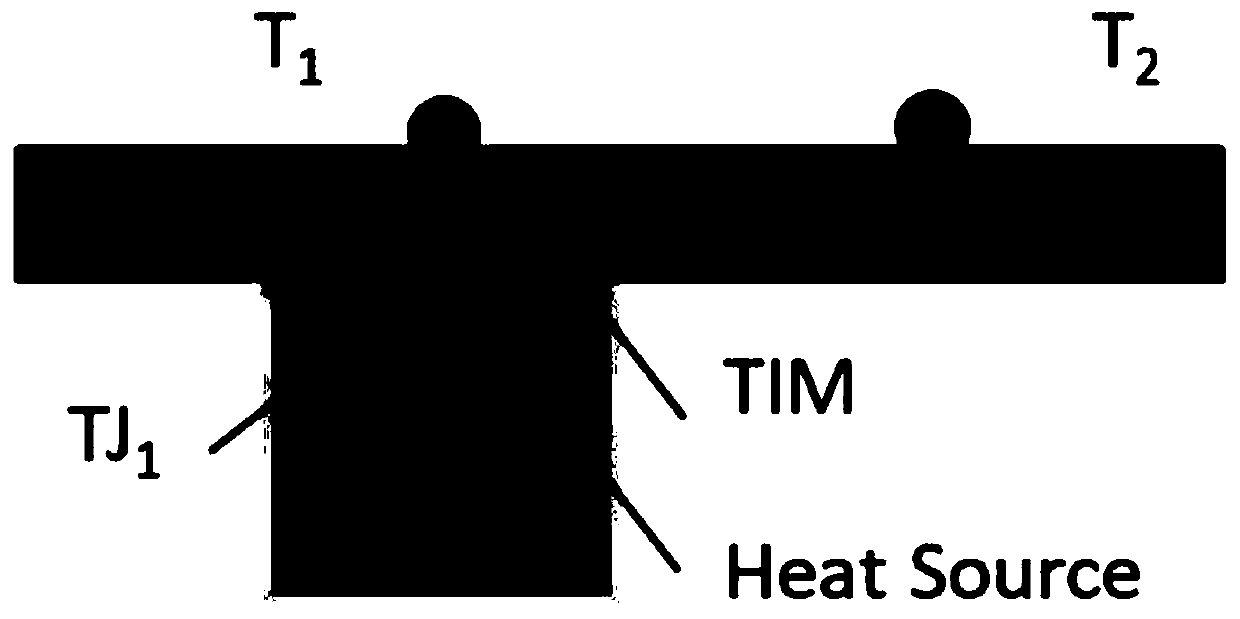

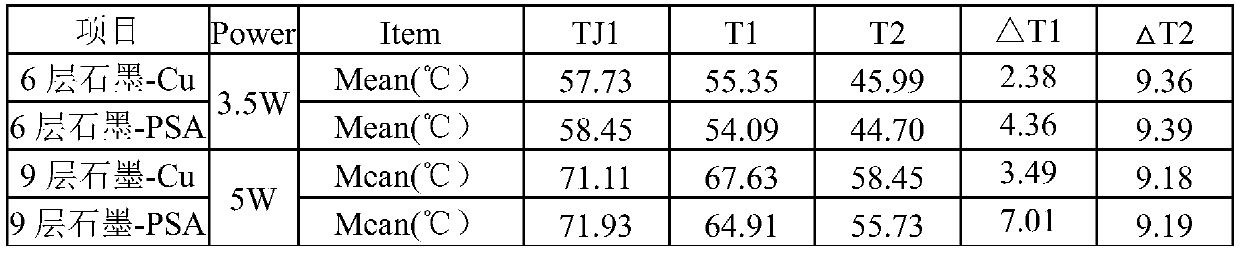

[0026] A composite graphite heat sink is prepared by using a 34 μm thick single-layer graphite film. The graphite film is prepared by high-temperature carbonization and graphitization of a polyimide film, and then vacuum magnetron sputtering Ti on both sides of the graphite film at the same time. (200nm) and Cu (1800nm) sputtering layer, and then cut the sputtered composite graphite film into 200*200mm square slices, stack up to 9 layers vertically, and the upper and lower outermost layers of the superimposed heat sink are single-layer graphite The superimposed composite graphite film is put into the designated tooling of the hot-press furnace for high-temperature and high-pressure welding and pressing.

[0027] The process of welding and pressing is as follows:

[0028] 0-650°C, pressure 0MPa, heating rate 5°C / min, and hold at 650°C for 60 minutes; 650-850°C, pressure rises to 20MPa, heating rate 10°C / min, and hold at 850°C for 60 minutes; 850-980°C , the pressure was mainta...

Embodiment 2

[0031] A composite graphite heat sink is prepared by using a 34 μm thick single-layer graphite film. The graphite film is prepared by high-temperature carbonization and graphitization of a polyimide film, and then vacuum magnetron sputtering Ti on both sides of the graphite film at the same time. (200nm) and Cu (1800nm) sputtering layer, and then cut the sputtered composite graphite film into 200*200mm square slices, stack up to 6 layers vertically, and the upper and lower outermost layers of the superimposed heat sink are single-layer graphite The superimposed composite graphite film is put into the designated tooling of the hot-press furnace for high-temperature and high-pressure welding and pressing.

[0032] The process of welding and pressing is as follows:

[0033] 0-650℃, pressure 0MPa, heating rate 10℃ / min, and keep at 650℃ for 120min; 650-850℃, pressure rise to 10MPa, heating rate 10℃ / min, and keep at 850℃ for 120min; 850-980℃ , the pressure was maintained at 20MPa, ...

Embodiment 3

[0036] A composite graphite heat sink is prepared by using a 34 μm thick single-layer graphite film. The graphite film is prepared by high-temperature carbonization and graphitization of a polyimide film, and then vacuum magnetron sputtering Ti on both sides of the graphite film at the same time. (200nm) and Cu (1800nm) sputtering layer, and then cut the sputtered composite graphite film into 200*200mm square slices, stack up to 4 layers vertically, and the upper and lower outermost layers of the superimposed heat sink are single-layer graphite The superimposed composite graphite film is put into the designated tooling of the hot-press furnace for high-temperature and high-pressure welding and pressing.

[0037] The process of welding and pressing is as follows:

[0038] 0-650℃, pressure 0MPa, heating rate 7.5℃ / min, and keep at 650℃ for 30min; 650-850℃, pressure 0MPa, heating rate 10℃ / min, and keep at 850℃ for 30min; 850-980℃, pressure Maintain at 20MPa, the heating rate is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com