Preparation method of diamond-loaded graphene thermal interface material for heat dissipation of electronic device

A technology of thermal interface materials and electronic devices, applied in the field of heat conduction materials, can solve problems such as reducing the service life of equipment, affecting the efficiency and reliability of electronic equipment, and increasing the operating temperature of electronic devices, so as to meet the needs of use and achieve high isotropic heat conduction Features, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

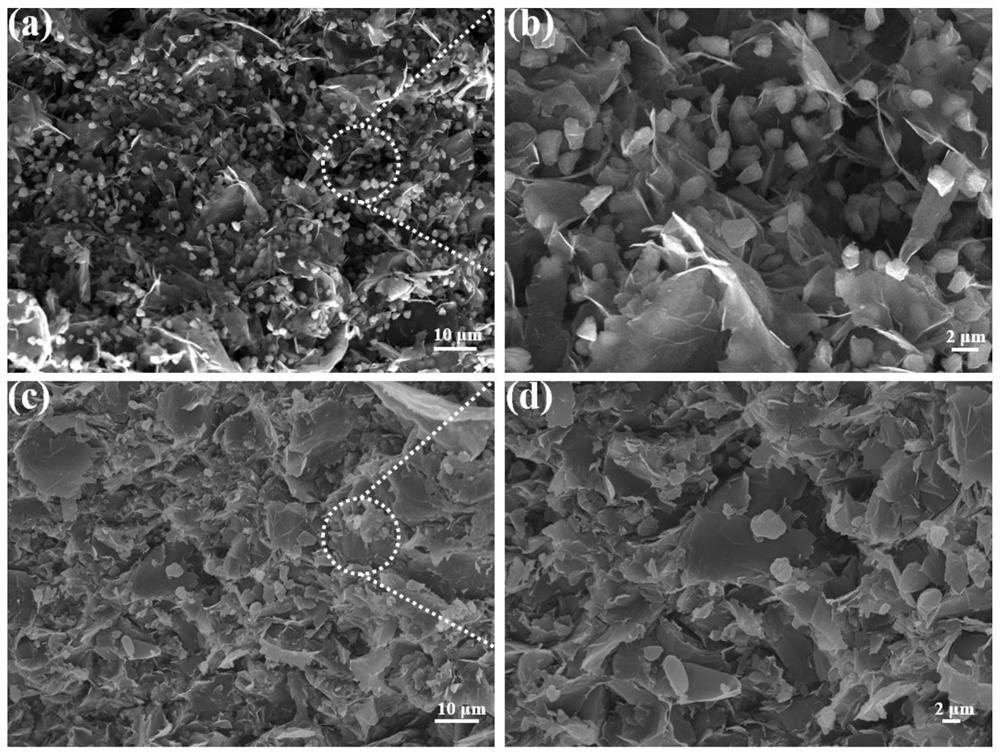

[0024] In this embodiment, the graphene-diamond mixed solution is suction-filtered to prepare the graphene thermally conductive framework precursor, and the graphene thermally conductive framework is obtained by high-temperature annealing, and the thermally conductive framework is compounded with epoxy resin to obtain the final thermal interface material. The specific preparation method is as follows:

[0025] 1) Take 100 mg of graphene sheets with an average sheet diameter of 18 μm, and perform ultrasonic treatment in absolute ethanol for 2 hours, so that the graphene is fully dispersed in ethanol, so that the average sheet diameter is reduced to 7 μm.

[0026] 2) Take 300 mg of diamond powder with a particle size of 2 μm and mix it with the ultrasonicated graphene solution for 1 hour.

[0027] 3) Suction-filter the sonicated solution in step 2) to remove the suction-filtered product, air-dry it naturally at room temperature, and perform high-temperature annealing treatment at...

Embodiment 2

[0033] In this embodiment, the graphene-diamond mixed solution is suction-filtered to prepare the graphene thermally conductive framework precursor, and the graphene thermally conductive framework is obtained by high-temperature annealing. After the thermally conductive framework is compounded with epoxy resin, the final thermal interface material is obtained. The specific preparation method is as follows:

[0034] 1) Take 550 mg of graphene sheets with an average sheet diameter of 18 μm, and perform ultrasonic treatment in absolute ethanol for 6 hours, so that the graphene is fully dispersed in ethanol, so that the average sheet diameter is reduced to 7 μm.

[0035] 2) Take 1650 mg of diamond powder with a particle size of 2 μm and mix it with the ultrasonicated graphene solution for 5 hours.

[0036] 3) Suction-filter the sonicated solution in step 2) to remove the suction-filtered product, air-dry it naturally at room temperature, and perform high-temperature annealing treat...

Embodiment 3

[0044] In this embodiment, the graphene-diamond mixed solution is suction-filtered to prepare the graphene thermally conductive framework precursor, and the graphene thermally conductive framework is obtained by high-temperature annealing. After the thermally conductive framework is compounded with epoxy resin, the final thermal interface material is obtained. The specific preparation method is as follows:

[0045] 1) Take 1000 mg of graphene sheets with an average sheet diameter of 18 μm, and perform ultrasonic treatment in absolute ethanol for 10 h, so that the graphene is fully dispersed in ethanol, so that the average sheet diameter is reduced to 7 μm.

[0046] 2) Take 3000 mg of diamond powder with a particle size of 2 μm and mix it with the ultrasonicated graphene solution for 3 hours.

[0047] 3) Suction-filter the sonicated solution in step 2) to remove the suction-filtered product, air-dry it naturally at room temperature, and perform high-temperature annealing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com