Preparation method of directionally distributed prestressed carbon fiber reinforced aluminum matrix composite

A technology of directional distribution and composite materials, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, conjugated artificial filaments, etc., can solve the problems of low thermal conductivity of copper and the influence of thermal conductivity of composite materials, etc., to improve thermal conductivity and improve Interface wettability, effect of improving longitudinal tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

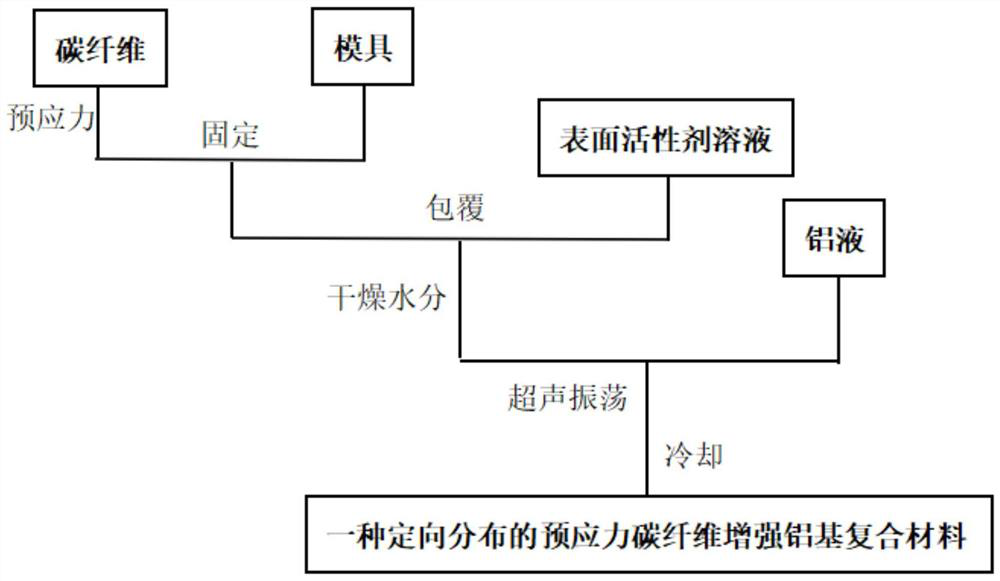

[0055] A kind of preparation method of the prestressed carbon fiber reinforced aluminum matrix composite material of directional distribution, comprises the following steps (such as figure 1 shown):

[0056] (1) Apply a pretension of 10 to 100 N to multiple strands of carbon fibers arranged in the same direction, and fix them with a mold to obtain oriented carbon fibers;

[0057] (2) Pour an aqueous solution of a surfactant with a mass fraction of 5 to 50wt.% into the mold, soak for 30 to 120 minutes, and dry to obtain carbon fibers coated with a surfactant; the surfactant is stearic acid , at least one of sodium dodecylbenzenesulfonate, lecithin, and alkyl glucoside;

[0058] (3) Pour liquid aluminum into the mold, vibrate with 500-1000W ultrasonic waves for 10-60 minutes, and then cool to obtain a carbon fiber reinforced aluminum matrix composite material.

[0059] Optionally, in step (1), the carbon fiber is a skin-core structure carbon fiber comprising a core and a skin;...

Embodiment 1

[0078] A method for preparing a directional distributed prestressed carbon fiber reinforced aluminum matrix composite material, comprising the following steps:

[0079] (1) Apply a pretension of 50N to 10 strands of carbon fibers aligned in the same direction, and fix them with a mold to obtain oriented carbon fibers;

[0080] (2) Pour a stearic acid aqueous solution with a mass fraction of 30wt.% into the mold, soak for 60 minutes, and dry to obtain carbon fibers coated with a surfactant;

[0081] (3) Pour molten aluminum into the mold, oscillate with 800W ultrasonic wave for 40 minutes, and cool to obtain carbon fiber reinforced aluminum matrix composite material.

Embodiment 2

[0083] Prepared according to the steps of Example 1, the difference from Example 1 is that the pretension in the step (1) is 10N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com