Graphene based heat-conducting interface material and preparation method thereof

A graphene-like material and graphene-based technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of high price and unfavorable general application, so as to improve the longitudinal thermal conductivity and facilitate the rapid export of heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a graphene-based thermal interface material, comprising the following steps:

[0033] A) Mix graphene-based materials, vinyl silicone rubber, hexagonal boron nitride, flake graphite, hydroxyl-terminated silicone oil, vinyl silicone oil, and the first silane coupling agent, and stir to obtain a rubber compound. The graphene-based material selected from graphene, graphene / silicon dioxide composite powder and graphene / silicon dioxide composite sheet material;

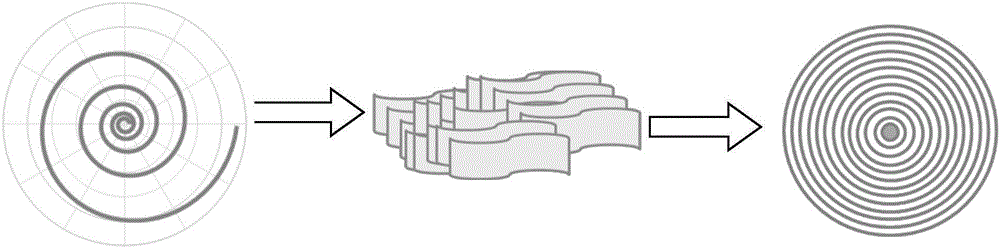

[0034] B) stretching, rolling and cutting the rubber material to obtain a graphene-based thermally conductive interface material.

[0035] see figure 1 , the preparation method of the graphene-based thermal interface material provided by the present invention is described in detail, figure 1 The process flow for preparing graphene-based thermal interface material for the present invention.

[0036] In the present invention, firstly, the graphene material, vinyl silico...

Embodiment 1

[0088] Firstly, the nano-silica powder is subjected to functionalization treatment, and the mass ratio of the nano-silica powder, water, and isopropoxy tristearic acid acyloxy titanate is preferably 5:1000:3.

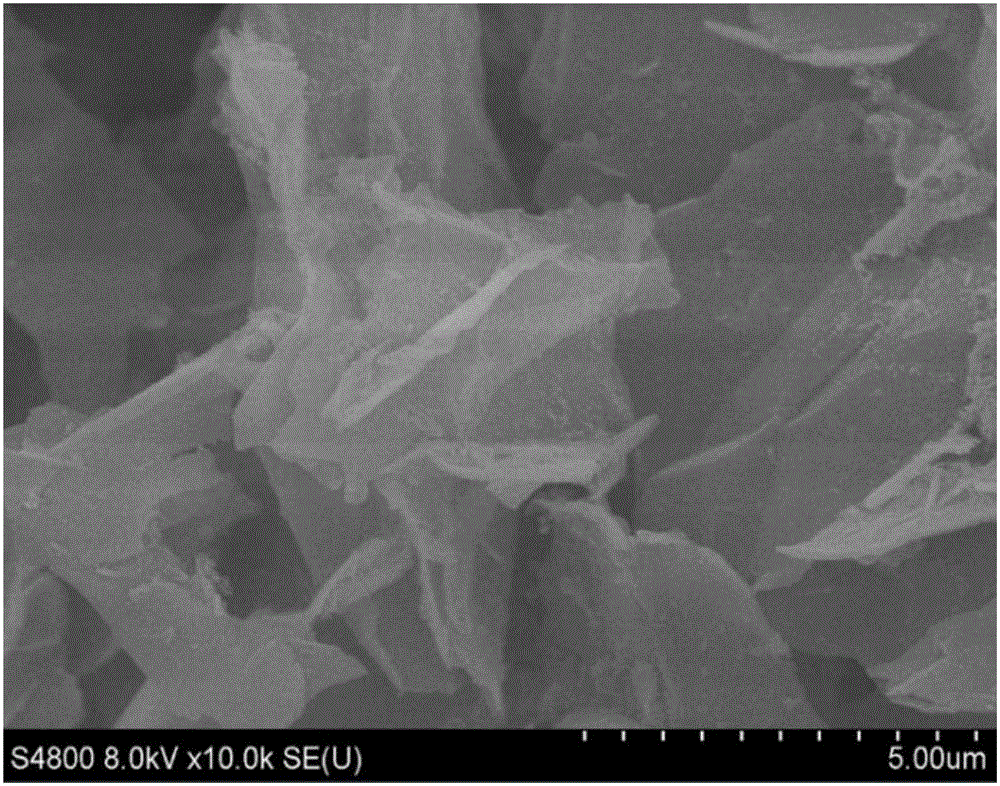

[0089] Then, the treated nano silicon dioxide and the graphene dispersion liquid are mixed and reacted, and the graphene composite film compounded with silicon dioxide is obtained by casting, and the film thickness is 10 microns.

[0090] Wherein, the mass ratio of the treated nano silicon dioxide and graphene dispersion is preferably 10:500. The temperature of the mixed reaction is preferably 60°C, and the time of the mixed reaction is preferably 6h; the graphene dispersion The mass ratio of graphene, water and sodium polyacrylate in the liquid is preferably 5:1000:0.1.

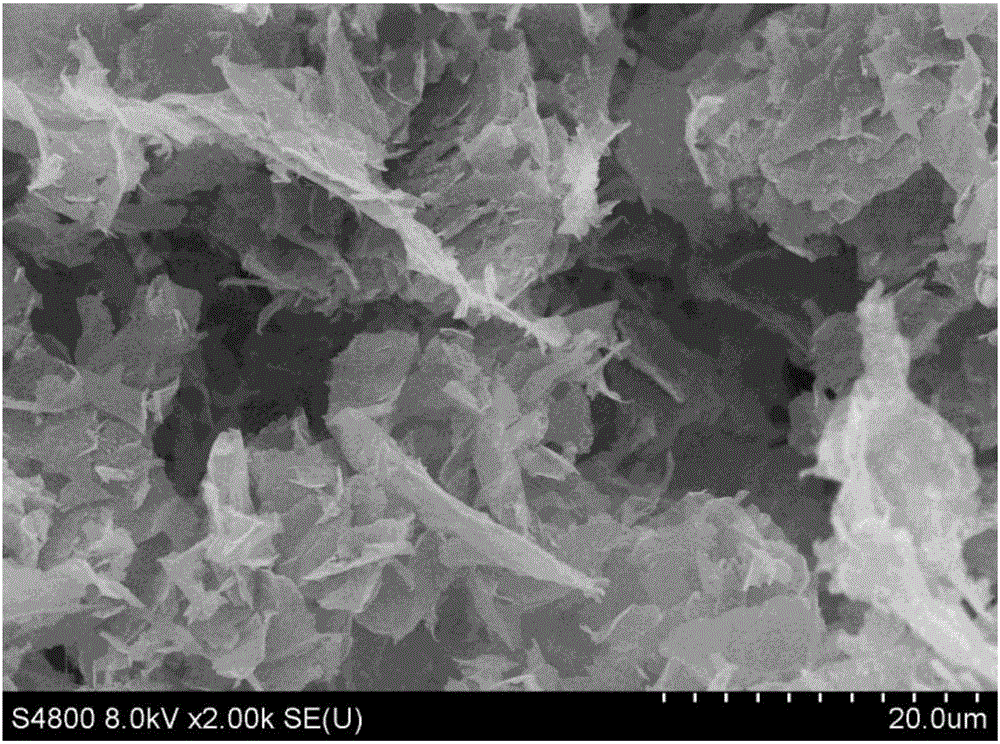

[0091] Take 12 parts of the above-mentioned graphene composite film, 100 parts of vinyl silicone rubber, 90 parts of hexagonal boron nitride, 85 parts of 75um flake graphite, 3.5 parts of hydroxyl-ter...

Embodiment 2

[0095] First, the nano-silica powder is functionalized, and the mass ratio of the nano-silica powder, water, and stearic acid is preferably 15:1000:10.

[0096] Then, the treated nano silicon dioxide and the graphene dispersion liquid are mixed and reacted, and the graphene composite film compounded with silicon dioxide is obtained by casting, and the film thickness is 15 microns.

[0097]Wherein, the mass ratio of the treated nano silicon dioxide and graphene dispersion is 10:800. The temperature of the mixed reaction is preferably 80°C, and the time of the mixed reaction is preferably 2h; the graphene dispersion The mass ratio of graphene, water and sodium alginate is preferably 10:1000:0.3.

[0098] Take 15 parts of the above-mentioned graphene composite film, 100 parts of vinyl silicone rubber, 90 parts of hexagonal boron nitride, 70 parts of 75um flake graphite, 1.5 parts of hydroxyl-terminated silicone oil, 6 parts of vinyl silicone oil, γ-methacryloxypropane 0.6 part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com