Composite powder, preparation method thereof and application of composite powder in heat dissipation coating

A technology of composite powder and heat-dissipating coating, applied in the direction of coating, heat exchange materials, chemical instruments and methods, etc., can solve the problems of high lateral thermal conductivity and difficult dispersion of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

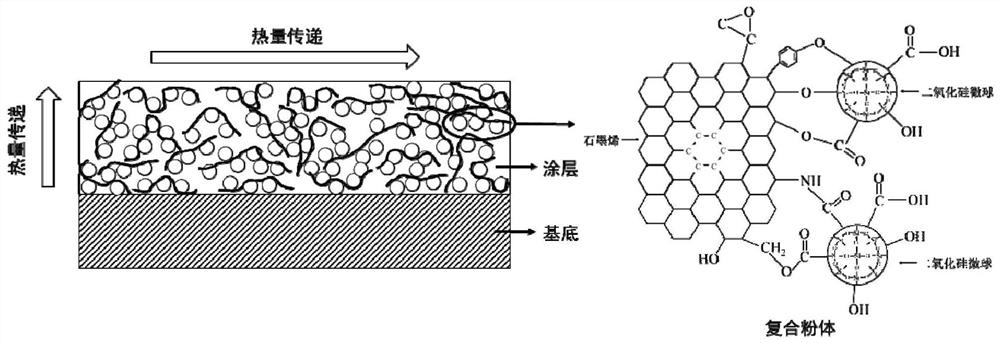

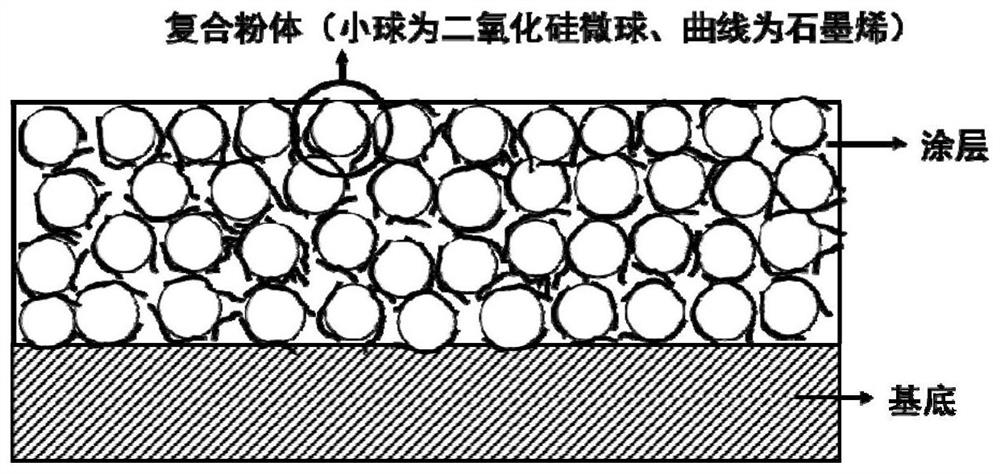

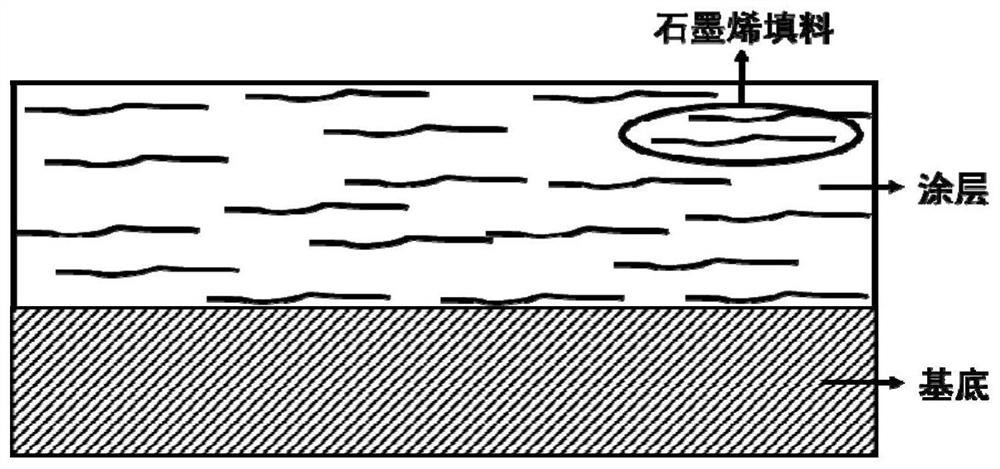

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 Preparation of composite powder

[0033] (1) Weigh 10g graphene (prepared by liquid phase exfoliation method, oxygen content is less than 3at.%, average lateral size is 22μm, sheet thickness is less than 3nm), 3g silica microspheres (particle size 3μm, surface modified with hydroxyl and Carboxyl, purchased from Zhongke Leiming Technology Co., Ltd.), 100g N-methylpyrrolidone (ACS, 98%), 0.5g epoxy organosilane (SH-023-7, Zaoyang Sihai Chemical Co., Ltd.), 0.2g 37% hydrochloric acid for use. In this embodiment, the graphene here is a powder with no groups and few defects, which is different from graphene oxide or modified graphene.

[0034] (2) 10g of graphene was added to 100g of N-methylpyrrolidone for shearing dispersion, the shear rate was 10000rpm, and the shearing time was 2h to obtain graphene dispersion liquid A.

[0035](3) 0.5 g of epoxy organosilane was added to the graphene dispersion liquid A obtained in step (2) and stirred evenly, and reacted in a c...

Embodiment 2

[0045] 2.1 Preparation of composite powder

[0046] (1) Weigh 10g graphene (prepared by liquid phase exfoliation method, oxygen content less than 3at.%, average lateral size 10μm, sheet thickness less than 3nm), 3g silica microspheres (particle size 10μm, surface modified with hydroxyl and Carboxyl group, purchased from Zhongke Leiming Technology Co., Ltd.), 1 kg of deionized water, 1 g of tannic acid (ACS), 10 g of KH560 silane coupling agent, for use.

[0047] (2) 1 g of tannic acid was added to 1 kg of deionized water, and stirred at 800 rpm for 0.5 h to obtain tannic acid solution A.

[0048] (3) 10g of graphene is added to the tannic acid solution A obtained in step (2) for shear dispersion, the shear rate is 10000rpm, and the shear time is 1h to obtain graphene dispersion liquid B.

[0049] (4) 10 g of KH560 silane coupling agent was added to the graphene dispersion liquid B obtained in step (3) and stirred evenly, and the temperature was raised to 90° C. for a consta...

Embodiment 3

[0059] 3.1 Preparation of composite powder

[0060] (1) Weigh 10g graphene (prepared by liquid phase exfoliation method, oxygen content is less than 3at.%, average lateral size is 22μm, lamella thickness is less than 3nm), 100ml concentrated sulfuric acid (98%), 2g potassium persulfate, 2g pentoxide Diphosphorus, 3 kg of deionized water, 3 g of silica microspheres (particle size 10 μm, surface modified with hydroxyl and carboxyl groups, purchased from Zhongke Leiming Technology Co., Ltd.), 10 ml of 37% hydrochloric acid, for use.

[0061] (2) 100ml of vitriol oil was added to the reactor, cooled to 0°C, then slowly added 2g potassium persulfate and 2g phosphorus pentoxide, stirred evenly and then heated to 80°C to obtain oxidant A.

[0062] (3) 10 g of graphene was added to the oxidant A obtained in step (2), stirred and reacted for 4 h, and then cooled to room temperature to obtain mixed solution B.

[0063] (4) Dilute the mixed solution B obtained in step (3) with 500 ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average horizontal size | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com