Graphite sheet and metal layer composed thermally conductive sheet and its composing method

A metal composite and graphite sheet technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of low production efficiency, unsatisfactory longitudinal thermal conductivity, and unsatisfactory thermal conductivity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

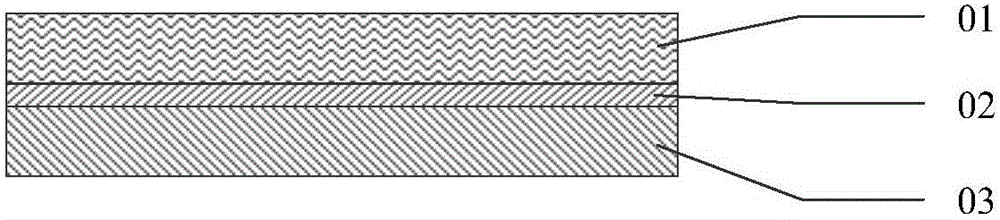

[0035] Such as figure 1 As shown, a thermally conductive sheet composed of a graphite sheet and a metal layer in this embodiment has a first graphite sheet layer 01, and a first metal deposition layer 02 on the first graphite sheet layer 01 is located on the first metal deposition layer. 02 is composed of a metal sheet layer 03 (thermal diffusion layer); the first metal deposition layer 02 is formed by the accumulation of metal particles on the surface of the first graphite sheet layer 01. The deposition in this implementation is physical vapor deposition (PVD), In terms of current technology, PVD technology is more environmentally friendly than other deposition technologies, especially compared to electroplating or electroless plating. With the advancement of technology, we have reason to believe that the optional deposition based on the present invention The technology is not limited to the PVD method; this is the embodiment where the metal sheet layer 03 and the first metal d...

Embodiment 2

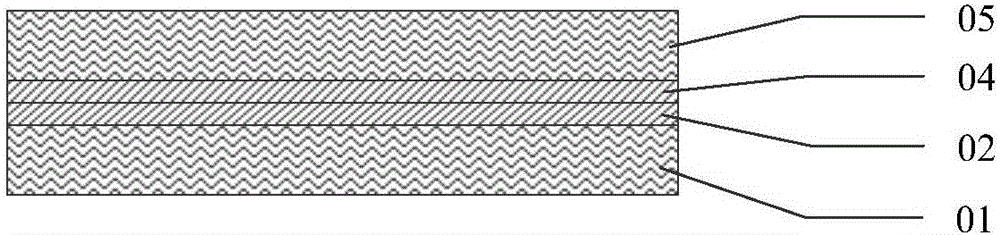

[0038] Such as figure 2 As shown, viewed from bottom to top, a thermally conductive sheet composed of a graphite sheet and a metal layer in this embodiment has a first graphite sheet layer 01, and a first metal deposition layer 02 on the first graphite sheet layer 01 is located Another metal deposition layer on the first metal deposition layer 02 is the second metal deposition layer 04, and another graphite sheet located on the second metal deposition layer 04 is the second metal deposition layer 05. In this embodiment, the first metal deposition layer 02 and the second metal deposition layer 04 are the same metal deposition layer, and both are aluminum deposition layers with a thickness of 10 μm. More specifically, after the first metal deposition layer 02 and the second metal deposition layer 04 are aligned, a pressure of 20Mpa generated between them is placed in a temperature environment of 600°C for 10 minutes. This embodiment also At the same time, nitrogen is filled in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com