A kind of diamond-like coating for piston ring surface, piston ring and preparation process

A preparation process and diamond technology, which is applied in the coating process of metal materials, piston rings, superimposed layers, etc., can solve problems such as insufficient durability, low friction performance, and large stress performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

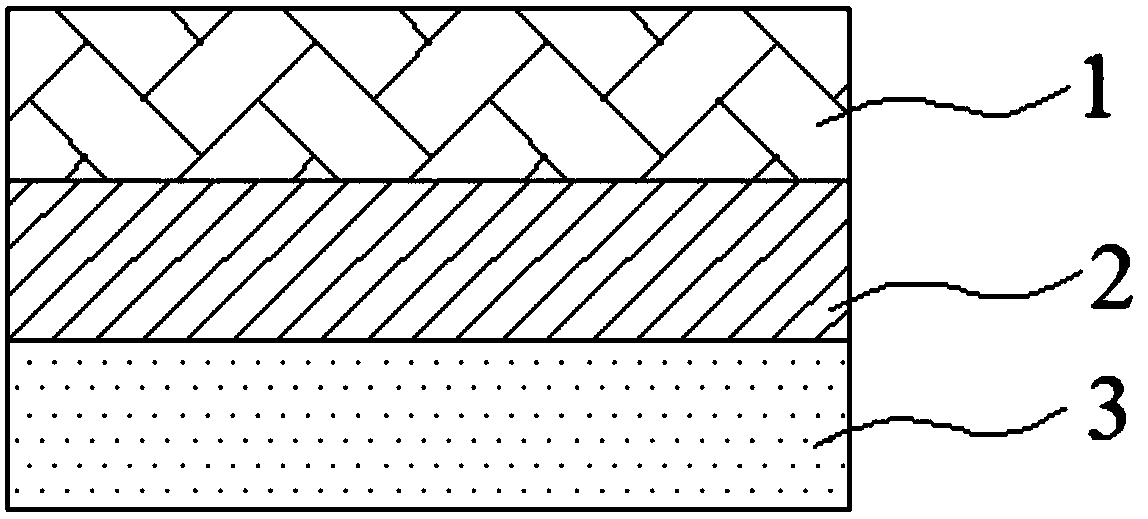

[0074] This embodiment is used for the diamond-like coating on the piston ring surface, such as figure 1 As shown, from bottom to top, it is the primer layer 3-Si layer, the gradient layer 2-SiC layer and the amplitude modulation layer 1-Si-DLC, that is, the DLC layer (diamond-like carbon coating) doped with Si. The thickness of the Si layer is 1 μm, the thickness of the SiC layer is 2 μm, the total thickness of the Si-DLC is 27 μm, and the total thickness of the diamond-like coating is 30 μm. The coefficient of friction of the diamond-like coating of the present embodiment under dry friction conditions is 0.11, such as Figure 6 shown.

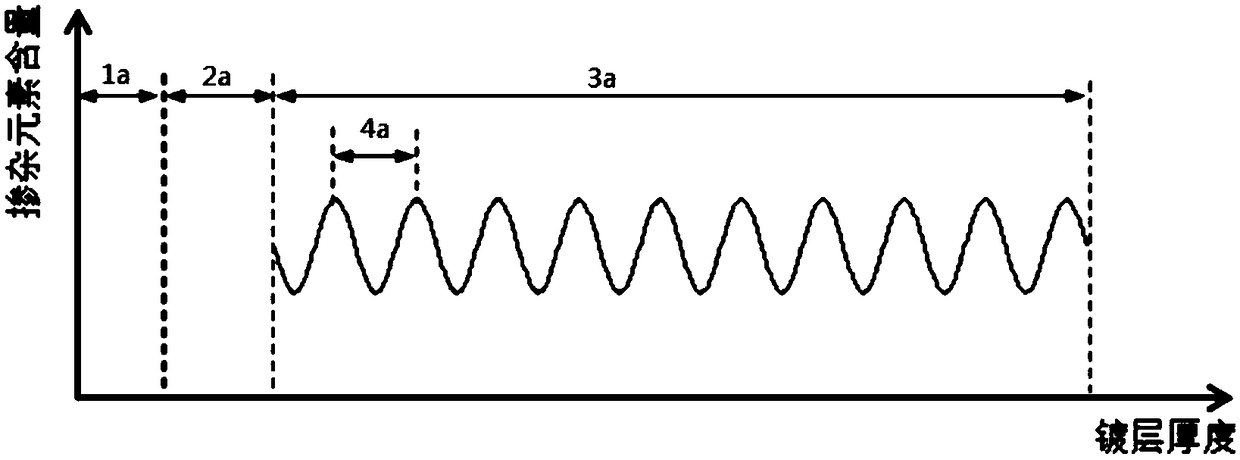

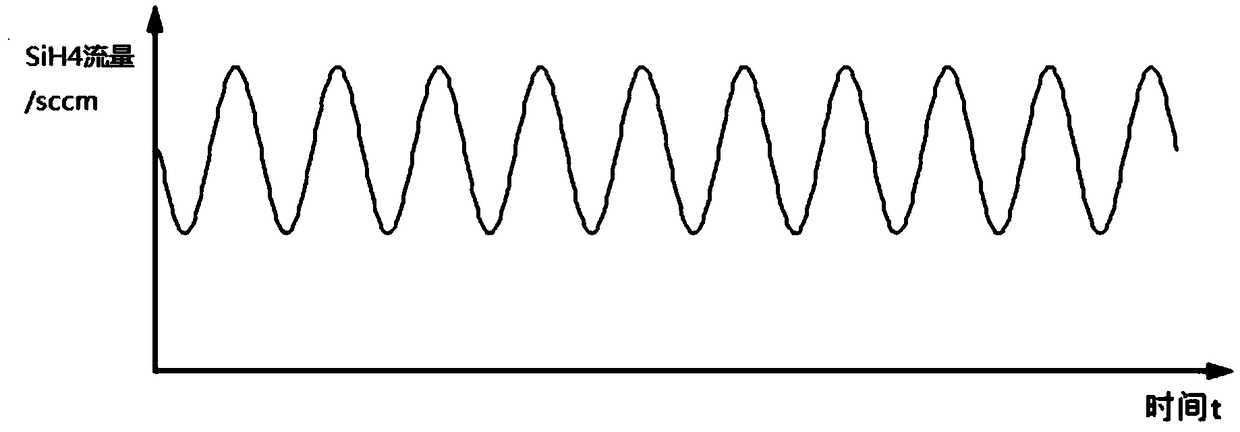

[0075] The content of Si element in the amplitude modulation layer 1 changes periodically with the thickness of the amplitude modulation layer 1 in the form of sinusoidal fluctuations, such as figure 2 as shown, figure 2 1a in corresponds to figure 1 The bottom layer 3, 2a in the corresponding figure 1 Gradient layer 2, 3a in the corre...

Embodiment 2

[0083] This embodiment is used for the diamond-like coating on the surface of the piston ring. From bottom to top, it is the primer layer-Si layer, the gradient layer-Si 0.8 C layer and AM layer - Si-DLC. Si layer thickness is 0.6μm, Si 0.8 The thickness of the C layer is 1.2 μm, the thickness of the Si-DLC is 18 μm, and the total thickness of the diamond-like coating in this embodiment is 19.8 μm. The friction coefficient of the diamond-like coating in this embodiment under dry friction conditions is 0.11.

[0084] The content of Si element in the amplitude modulation layer changes periodically with the thickness of the amplitude modulation layer in the form of sinusoidal fluctuations. There are 45 cycles in the amplitude modulation layer, that is, the fluctuation cycle of the sine wave is 45, and the thickness of the amplitude modulation layer corresponding to each fluctuation cycle is 0.4 μm. The content of Si in the amplitude modulation layer corresponding to the trough...

Embodiment 3

[0091] This embodiment is used for the diamond-like coating on the surface of the piston ring. From bottom to top, it is the primer layer—Cr layer, gradient layer—CrC layer and amplitude modulation layer—Cr-DLC, that is, the DLC layer doped with Cr (like diamond coating). Among them, the thickness of the underlying Cr layer is 1 μm, the thickness of the CrC layer is 2 μm, the total thickness of the CrC-DLC amplitude modulation layer is 27 μm, and the total thickness of the diamond-like coating in this implementation is 30 μm. The friction coefficient of the diamond-like coating in this embodiment under dry friction conditions is 0.09.

[0092] The content of Cr element in the amplitude modulation layer changes periodically with the thickness of the amplitude modulation layer in the form of sinusoidal fluctuations. There are 50 cycles in the amplitude modulation layer, that is, the fluctuation cycle of the sine wave is 50, and the thickness of the amplitude modulation layer co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com