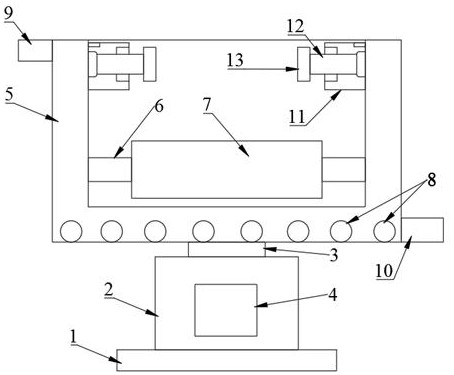

A dual-axis temperature control turntable and its temperature control system

A technology of turntable and axis control, which is applied in the direction of workbench, electric temperature control, manufacturing tools, etc. It can solve the problems of slow temperature adjustment speed, non-concentrated heat conduction, short constant temperature control time, etc., and achieve temperature adjustment speed Fast, reduce heat loss, constant temperature control time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

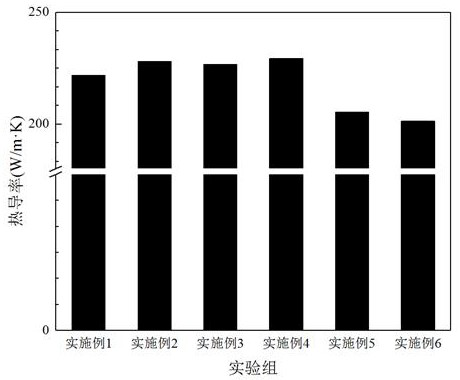

Embodiment 1

[0018] The processing method one of the operating table comprises the following steps:

[0019] (1) configure the aqueous solution of chloroiridic acid, the mass percentage of solute in the aqueous solution of chloroiridic acid is 5%, configure dilute hydrochloric acid solution, the mass percentage of solute in the described dilute hydrochloric acid solution is 5%, the rest water; soak the magnesium mesh in dilute hydrochloric acid solution and etch for 1min, then take it out, wash it 3 times with deionized water, and dry it; soak the dried magnesium mesh in the aqueous solution of chloroiridic acid, then take it out, and dry it dry, after drying, soak again in the aqueous solution of chloroiridic acid, then take it out and dry; repeat the steps of soaking the aqueous solution of chloroiridic acid and drying for a total of 10 times, and then place it at 400°C for calcination for 2h to obtain the coated Magnesium mesh covered with iridium oxide;

[0020] (2) The aluminum alloy...

Embodiment 2

[0024] The second processing method of the operating table comprises the following steps:

[0025](1) configure the aqueous solution of chloroiridic acid, the mass percentage of solute in the aqueous solution of chloroiridic acid is 6%, configure dilute hydrochloric acid solution, the mass percentage of solute in the described dilute hydrochloric acid solution is 5%, the rest water; soak the magnesium mesh in dilute hydrochloric acid solution and etch for 1min, then take it out, wash it 3 times with deionized water, and dry it; soak the dried magnesium mesh in the aqueous solution of chloroiridic acid, then take it out, and dry it dry, after drying, soak again in the aqueous solution of chloroiridic acid, then take it out and dry; repeat the steps of soaking the aqueous solution of chloroiridic acid and drying for a total of 10 times, and then place it at 400°C for calcination for 2h to obtain the coated Magnesium mesh covered with iridium oxide;

[0026] (2) The aluminum all...

Embodiment 3

[0030] The processing method three of the operating table comprises the following steps:

[0031] (1) configure the aqueous solution of chloroiridic acid, the mass percentage of solute in the aqueous solution of chloroiridic acid is 7%, configure dilute hydrochloric acid solution, the mass percentage of solute in the described dilute hydrochloric acid solution is 5%, the rest water; soak the magnesium mesh in dilute hydrochloric acid solution and etch for 1min, then take it out, wash it 3 times with deionized water, and dry it; soak the dried magnesium mesh in the aqueous solution of chloroiridic acid, then take it out, and dry it dry, after drying, soak again in the aqueous solution of chloroiridic acid, then take it out and dry; repeat the steps of soaking the aqueous solution of chloroiridic acid and drying for a total of 10 times, and then place it at 420° C. for calcination for 1 hour to obtain the coated Magnesium mesh covered with iridium oxide;

[0032] (2) The alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com