Three-dimensional heat-conducting and wave-absorbing reinforced composite film and preparation method thereof

An enhanced composite and three-dimensional technology, applied in chemical instruments and methods, manufacturing tools, welding equipment, etc., can solve problems such as low thermal conductivity and electromagnetic shielding efficiency, difficult filling of thermal conductive powder and wave-absorbing powder, and reduction of material strength , to achieve the effect of being conducive to graphene coating, improving the longitudinal thermal conductivity and mechanical strength, and improving the bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] Preparation Example 1 provides a kind of MXene nanosheet, and the following takes Preparation Example 1 as an example to illustrate.

[0053] The MXene nano sheet that preparation example 1 provides, its preparation steps are:

[0054] S1. Add 100g LiF to 500mL HCl solution with a mass fraction of 35wt% for stirring, control the stirring speed to 1000rpm, and stir for 15min to obtain an etching solution containing HF;

[0055] S2. Weigh 80g MAX phase Ti 3 AlC 2 , added to the above HF-containing etching solution to stir, control the stirring speed to 1800rpm, stir for 8h, centrifuge after stirring, wash 3 times with deionized water, and obtain an accordion-shaped MXene multilayer structure;

[0056] S3. Add the above-mentioned accordion-shaped MXene multilayer structure into deionized water for ultrasonication. The ultrasonic time is 10 hours. Control the ultrasonic frequency and ultrasonic power to convert the accordion-shaped MXene multilayer structure into MXene na...

preparation example 2

[0057] Preparation examples 2-4 provide a graphene oxide / MXene thin film, and preparation example 2 is taken as an example to illustrate below.

[0058] The graphene oxide / MXene film that preparation example 2 provides, its preparation steps are:

[0059] S1. Mix 1 g of MXene nanosheets prepared in Preparation Example 1 with 5 L of graphene oxide slurry with a concentration of 1 g / L, and ultrasonically disperse them for 30 min at an ultrasonic power of 200 W to obtain a composite slurry;

[0060] S2. Transfer the above-mentioned composite slurry to a precision coating machine, coat it on the substrate with a thickness of 50 μm, raise the temperature to 100 °C at a rate of 5 °C / min, dry for 2 hours, and then send it into the graphitization furnace. After 30 minutes of argon gas, the temperature in the graphitization furnace was raised to 2500°C, heated at 2500°C for 1 hour, and cooled to room temperature after heating to obtain a graphene oxide / MXene film.

[0061] The differe...

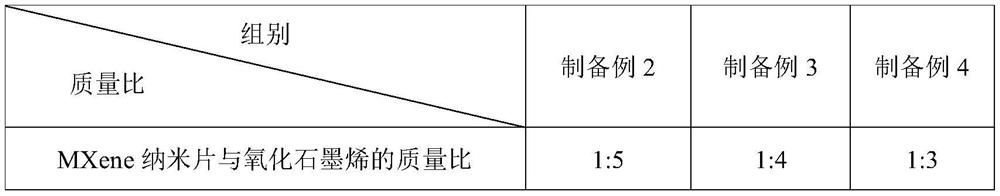

preparation example 2-4

[0062] Table 1 Preparation Example 2-4 The mass ratio of MXene nanosheets to graphene oxide

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com