Graphite aluminum high-thermal-conductivity module with low longitudinal thermal resistance

A high thermal conductivity, vertical technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, electrical components, etc., can solve the problems of graphite aluminum application restriction, slow heat transfer, etc., to improve the longitudinal thermal conductivity, enhance Thermal conductivity, the effect of reducing longitudinal thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

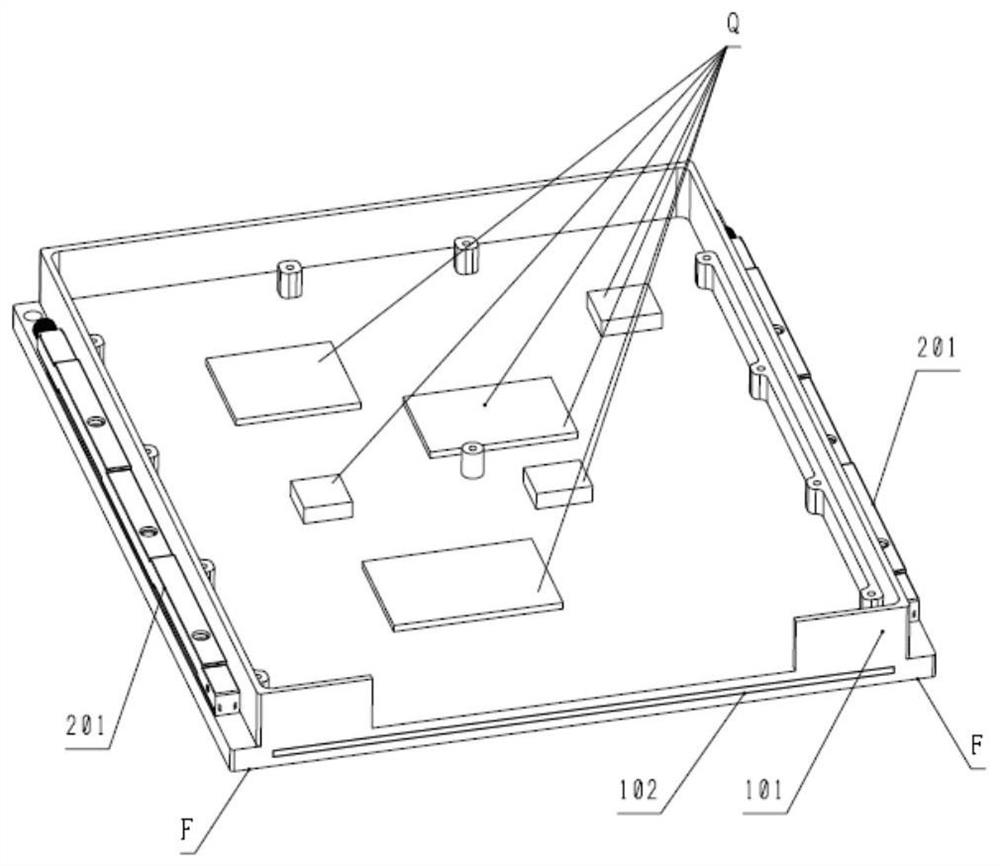

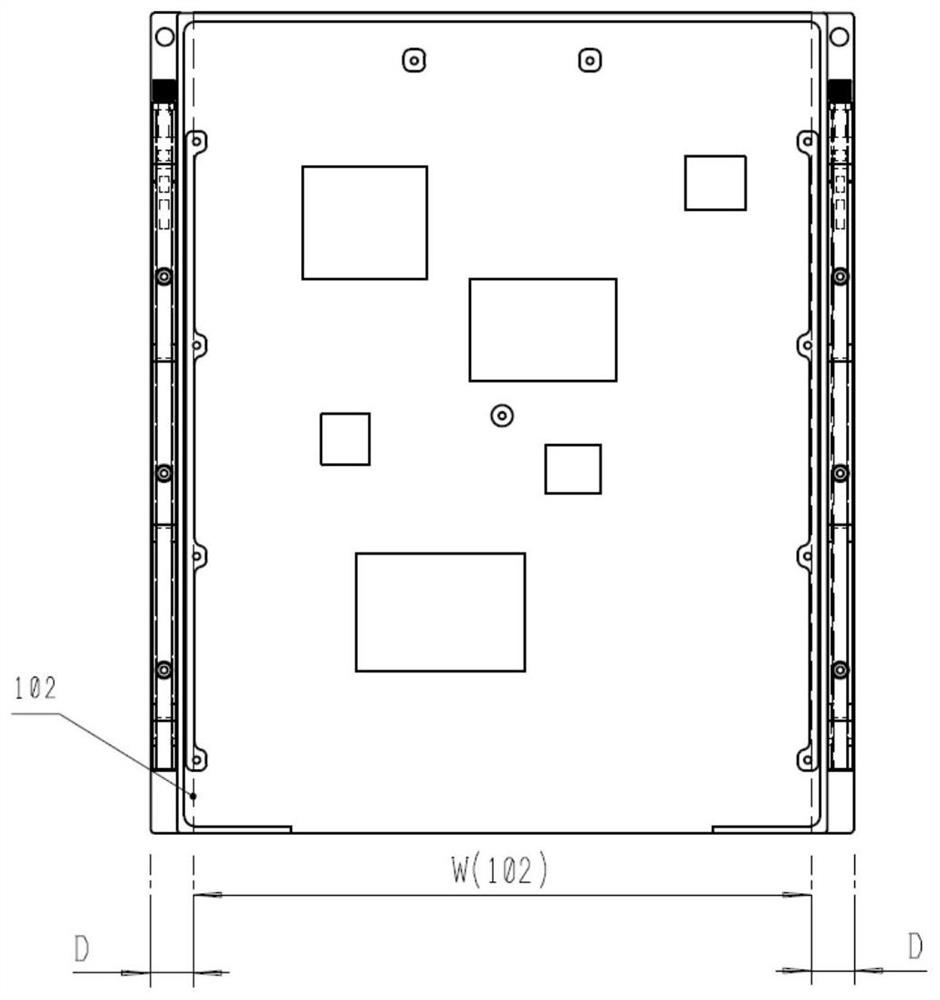

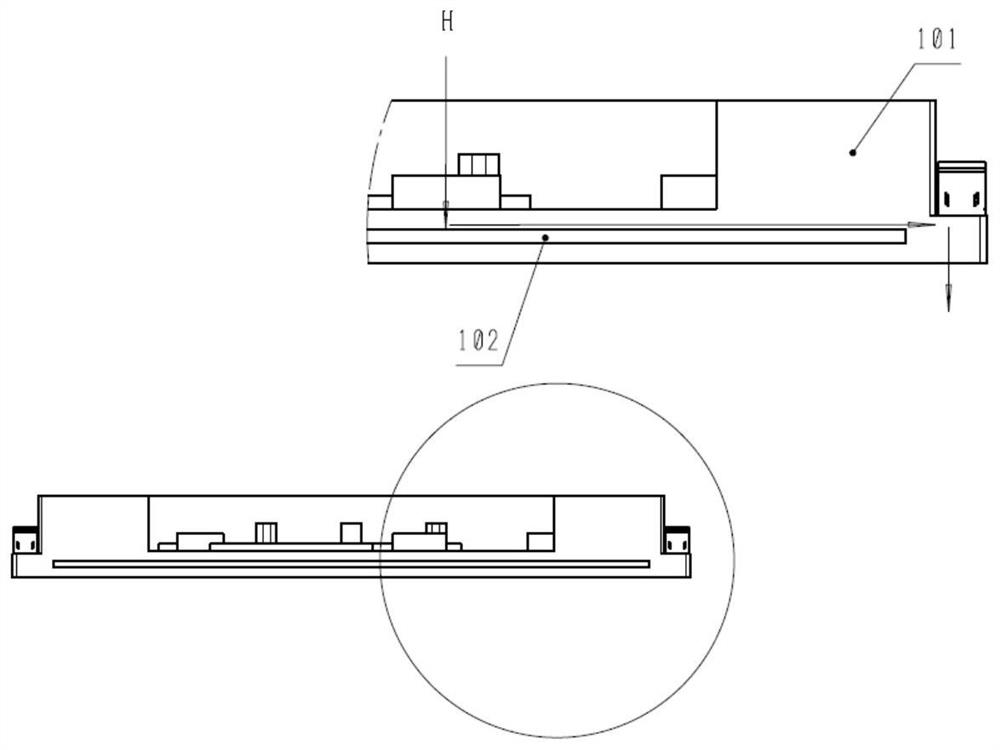

[0025] as attached figure 1 As shown, it is a schematic diagram of the box body shape of a graphite aluminum high thermal conductivity module with low longitudinal thermal resistance provided in this embodiment. Station Q, a high thermal conductivity interlayer 102 is embedded inside the box body 101, locking strips 201 are provided on both sides of the box body 101, and the back side of the locking strips 201 on the box body 101 is the external heat exchange surface F of the box body. The heat conduction interlayer is not fully covered inside the box body, and the external heat exchange surfaces F on both sides are not fully covered with high heat conduction structures.

[0026] The upper boss Q of the box body 101 is a part in contact with the heat generating device, and the heat generating device transfers heat to the graphite aluminum high thermal conductivity module through the boss Q. The back side F of the locking bar 201 on the box body 101 is the outer heat exchange ...

Embodiment 2

[0031] as attached Figure 4 As shown, it is a schematic diagram of a comparison test of thermal conductivity of a graphite aluminum high thermal conductivity module with low longitudinal thermal resistance provided in this embodiment, a graphite aluminum high thermal conductivity module with graphite aluminum covering the entire module area, and a module made of pure aluminum alloy.

[0032] The external dimensions of the three modules A, B, and C are exactly the same, and the module A is the graphite aluminum high thermal conductivity module with low longitudinal thermal resistance provided by embodiment 1. Module B is a graphite aluminum high thermal conductivity module with graphite aluminum covering the entire module area. Module C is a module made of pure aluminum alloy. The heat test positions of the three modules are points QA1~QC3 in the figure, the heat loading position is the boss corresponding to the test point, and the external heat exchange surface of the module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com