Compound type black acid dye

A technology of acid dyes and neutral dyes, applied in the field of printing and dyeing, can solve the problems of poor chromatographic breadth, increase product production cost, take a long time, etc., achieve better saturation and performance, improve product quality, and solve the problem of poor reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 composite type black acid dye

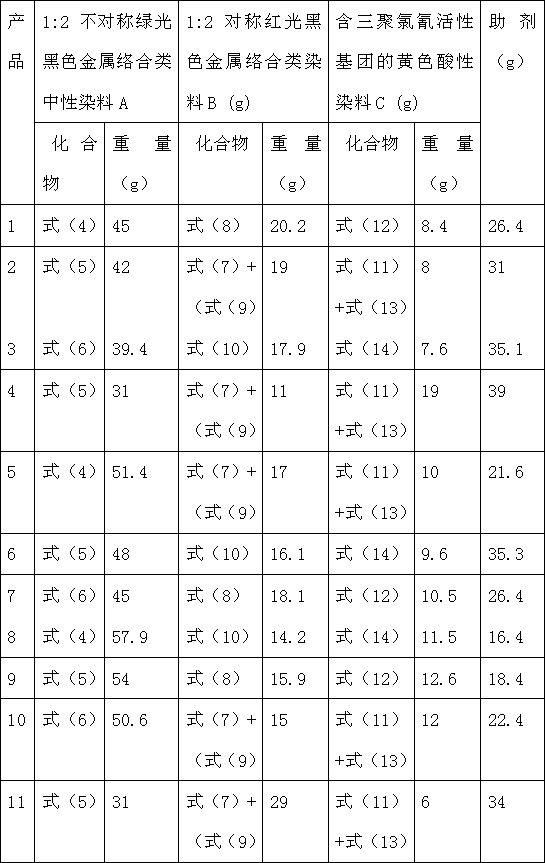

[0037] According to the data of each component in Table 1, compounds A, B, C and appropriate amount of additives were added to water and mixed evenly, and then spray-dried to prepare dyes 1-9.

[0038] Table 1

[0039]

[0040] The above mixing method is for compound A with different cations and adding different proportions of gray tone compound B and yellow compound C. According to the needs of different customers, the color tone after dyeing is adjusted, taking into account the product application performance and the economic benefits of product compounding. A group of black acid dyes with high dyeing strength, good fastness and good color expression can be obtained.

Embodiment 2

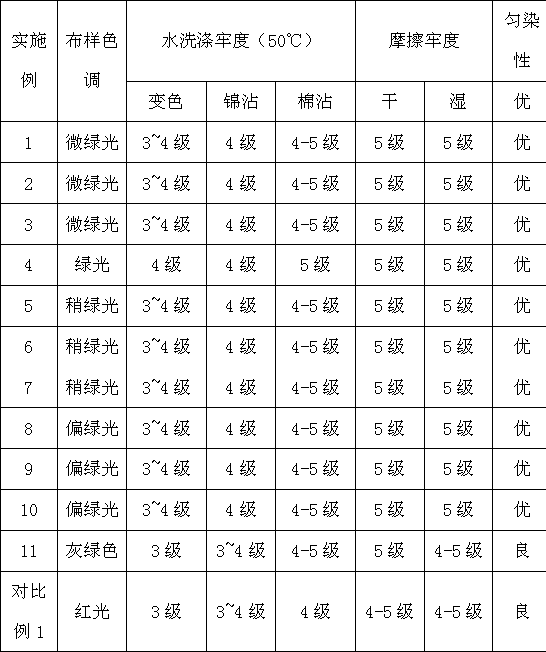

[0041] Embodiment 2 Performance testing of products 1 to 9

[0042] Detection method:

[0043] Take 0.5g of the original powder of compound A of the formula (1) and 0.5g each of the dyes 1 to 9 obtained in Example 1, and make solutions with a concentration of 0.5g / 500ml with water, draw 20ml and mix with 180ml of water, and then put Add 2g of nylon 66, add 5ml of 5% sodium sulfate and 5ml of weak acid buffer, heat up to 95°C for 1 hour, cool down to 50°C, take out the fabric, rinse it with clean water, put it in a 60°C oven for drying, Obtain comparative example product, and the printing and dyeing product of dyestuff 1~9 of the present invention.

[0044] Test the color tone, water washing fastness, rubbing fastness and level dyeing of the comparative products and products 1~9 respectively, according to the specific AATCC test standards, and the test results are shown in the following table:

[0045] Table 2

[0046]

[0047] The above test data show that the compounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com