Reactive black dye composition

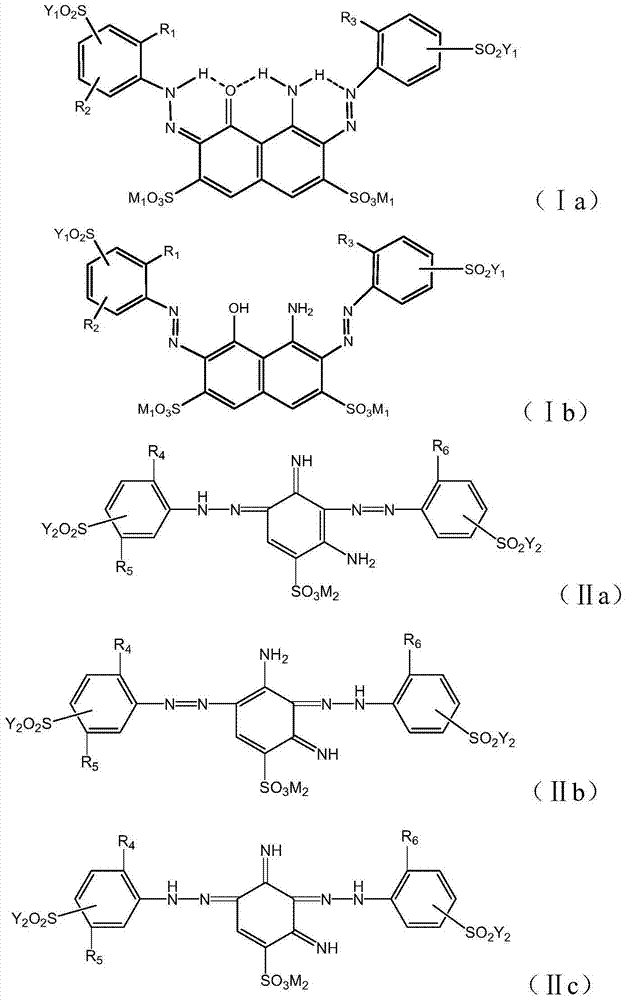

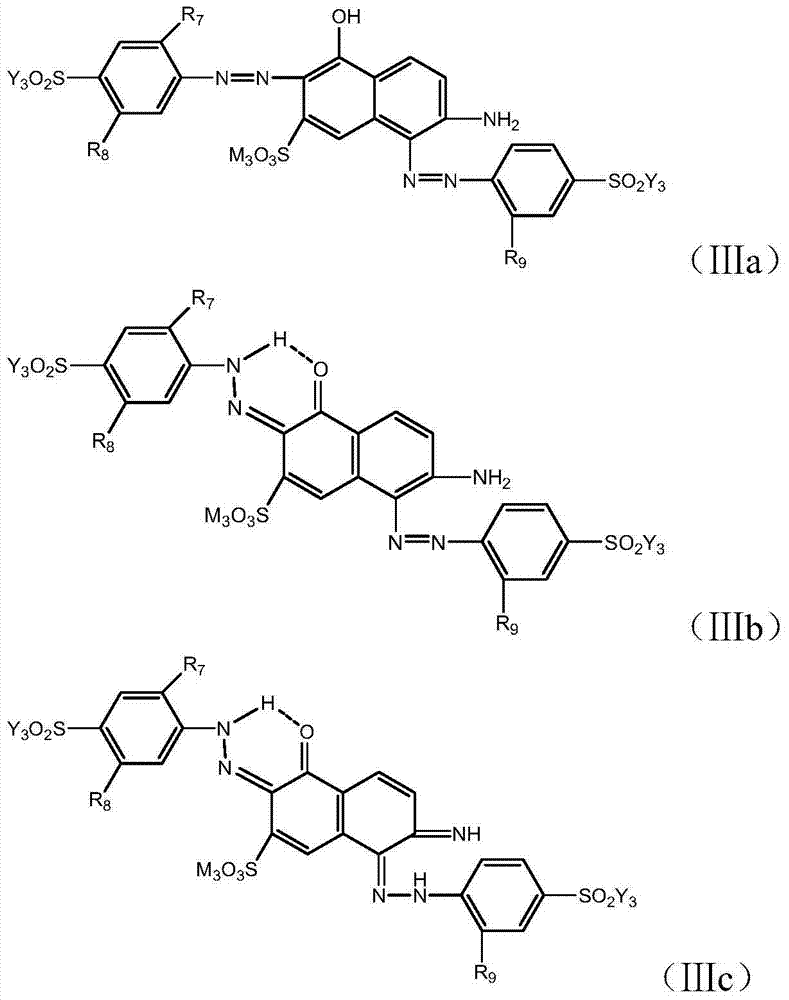

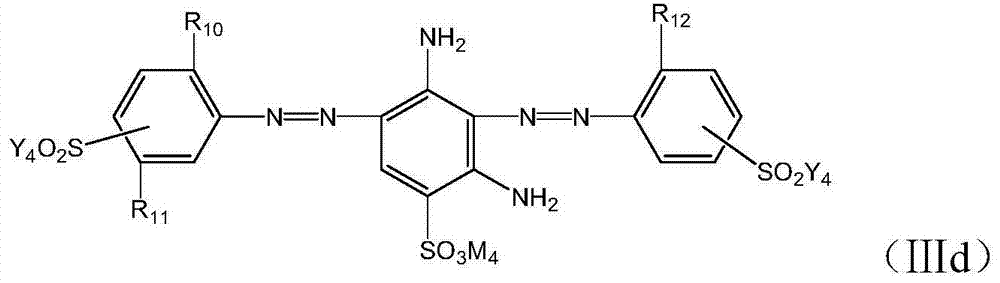

A dye composition and the technology of the composition are applied in the directions of organic dyes, dyeing methods, textiles and paper making, etc., and can solve the problems of weak dye depth, difficult cleaning of dyed fabrics, insufficient blackness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Preparation of dye compounds of formula (IIa-1):

[0079] (1) Diazotization: Add 45.5g of sulfonated para-ester (ie 4-β-ethylsulfone sulfate aniline-2-sulfonic acid) to 150mL of water and stir evenly, add ice and cool to 2-5 ℃, add 7.0ml of 31% (w / w) hydrochloric acid, beat for 30-40 minutes, add 30.2g of 30% (w / w) sodium nitrite solution dropwise from the liquid surface at 2-5 ℃, and keep the temperature at 5 ~10°C, pH=1.0~1.3, stirring and reacting for 2~3 hours under the condition of color development of potassium iodide test paper, maintaining a slight excess of sodium nitrite during the dropwise addition and reaction, and eliminating the excess sodium nitrite with sulfamic acid to obtain 4-β-Ethylsulfone sulfate aniline-2-sulfonic acid diazo solution.

[0080] (2) Diazotization: add 35.5g of p-ester (i.e. p-(β-hydroxyethylsulfone sulfate) aniline) to 80mL of water and stir evenly, then add ice and cool to 2-5°C, and keep for 2-5 Slowly add 14ml of 31% hydrochlori...

Embodiment 2

[0085] Mechanically mix 59 parts of dyes of formula (Ia-3), 25 parts of dyes of formula (IIa-1), 16 parts of dyes of formula (Ⅲb-1) and 2.5 parts of sodium sulfate, and the obtained composite dyed cotton is deep black, where M 1 , M 2 , M 3 All are Na, that is, the dye compound is expressed in the form of sodium salt.

[0086]

[0087]

Embodiment 3~72

[0089] Mechanically mix the dyes listed in Table 1 (where M 1 ~ M 4 Both are Na, that is, the dye compounds are all in the form of sodium salts), dyed cotton is black.

[0090]

[0091]

[0092]

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com