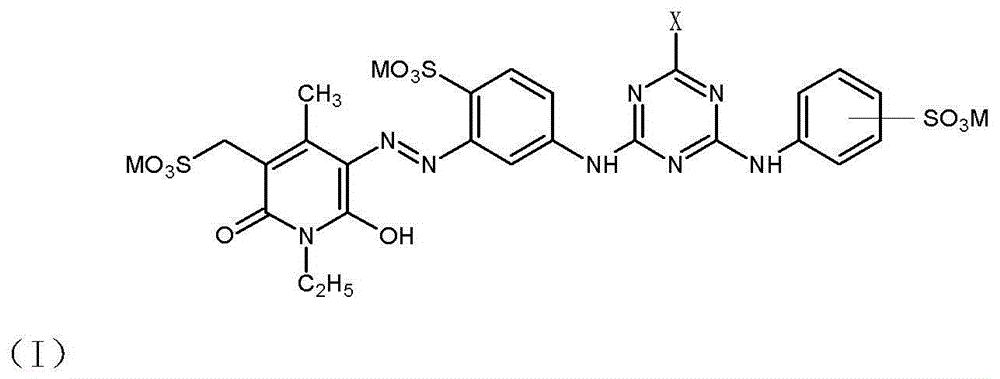

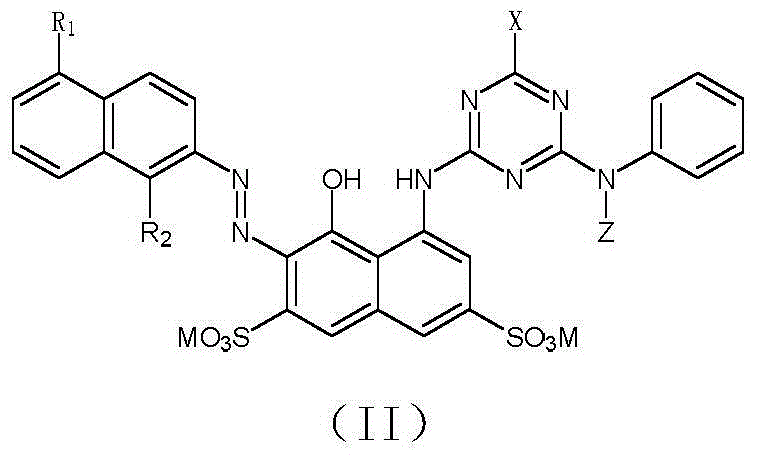

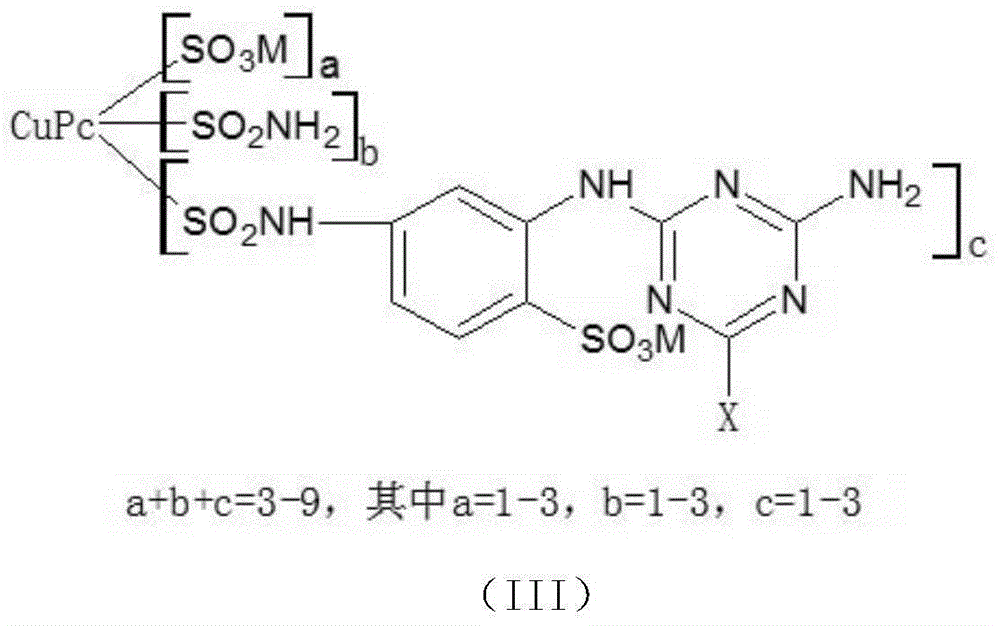

Novel activated printing ink and preparation method thereof as well as direct printing technology

A kind of ink, active technology, applied in the direction of ink, dyeing, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1 Preparation of new reactive gravure printing ink and its production process of gravure direct printing on dry cotton cloth containing alkali pulp 1

[0090] Production materials: Cotton fabric mercerized and bleached semi-finished products

[0091] Dyeing chemicals: new reactive dye yellow, new reactive dye red, new reactive dye blue, new reactive dye black, new reactive dye orange, new reactive dye navy blue, new reactive dye brilliant blue (produced by Zhejiang Yide Chemical Co., Ltd.), urea , sodium m-nitrobenzene sulfonate, ancient oil, sodium dodecylbenzene sulfonate, dihydrogen phosphate and dihydrogen phosphate compound, 5% sodium alginate paste, fungicide, sodium bicarbonate, soap Lotion (2g / L soap flakes, 2g / L soda ash).

[0092] Production equipment: uniform padding car, shaping dryer, improved gravure printing machine, steam box, flat car wash.

[0093] 1. Preparation of new reactive gravure ink

[0094] 1.1 Preparation prescription of new reacti...

Embodiment 2

[0128] Example 2 Preparation of new reactive flexo printing ink and its production process of gravure direct printing on dry cotton cloth containing alkali pulp 2

[0129] Production materials: Cotton fabric mercerized and bleached semi-finished products

[0130]Dyeing chemicals: new reactive dye yellow, new reactive dye red, new reactive dye blue, new reactive dye black (produced by Zhejiang Yide Chemical Co., Ltd.), urea, sodium m-nitrobenzene sulfonate, swire oil, dodecyl Sodium benzenesulfonate, dihydrogen phosphate and dihydrogen phosphate compound, 1% modified wild plant seed collagen paste, fungicide, sodium hydroxide, sodium silicate, soaping liquid (2g / L soap flakes, 2g / L soda ash).

[0131] Production equipment: uniform padding car, shaping dryer, improved gravure printing machine, steam box, flat car wash.

[0132] 1. Preparation of new reactive flexo printing ink

[0133] 1.1 Preparation prescription of new reactive flexo printing ink

[0134] Table-9 Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com