Disperse blue to black dye composition, dye product and applications thereof

A technology of black dye and disperse blue, applied in the field of disperse blue to black dye compositions and dye products thereof, can solve the problems such as the decrease of dyeing fastness to wet treatment, the influence on the export of dyed fabrics, and the inability to meet the environmental protection requirements of Class II , to achieve good wet fastness and rubbing fastness, and meet the needs of ecological and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

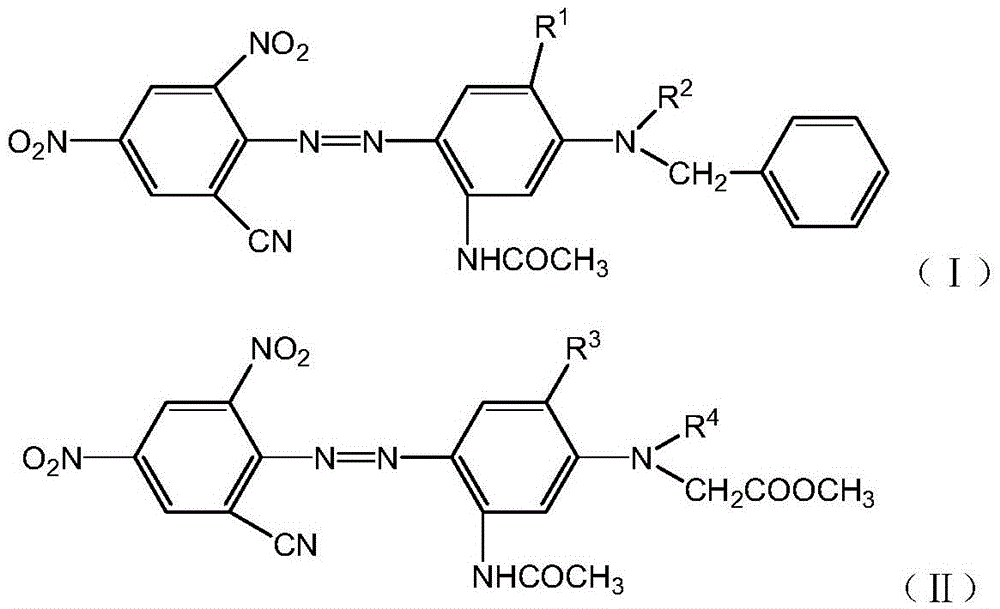

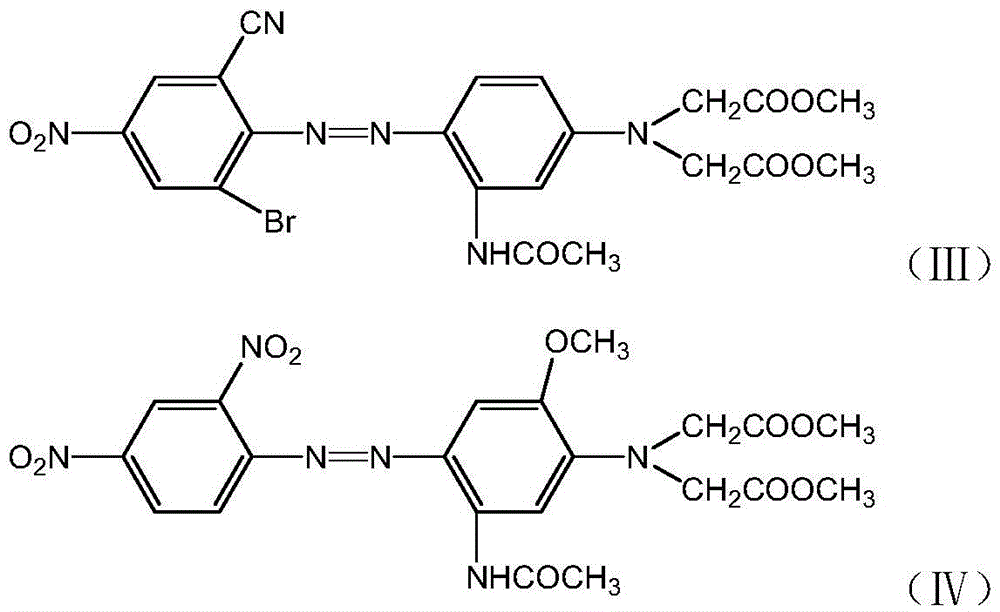

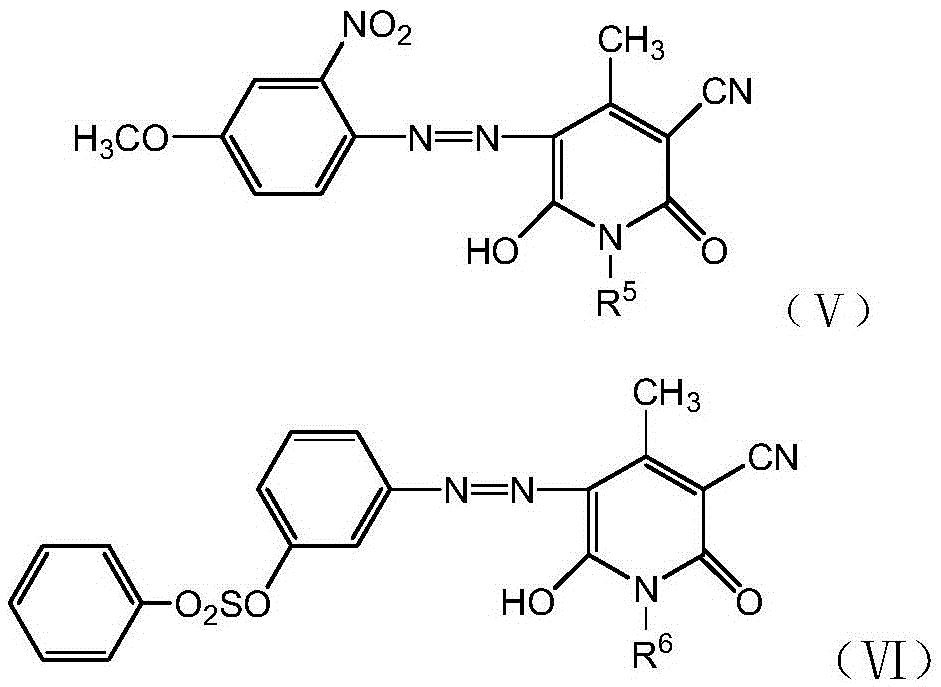

Image

Examples

Embodiment 1

[0051] 30 grams of formula (I-2), 25 grams of formula (II-1), 10 grams of formula (Ⅲ), 5 grams of formula (Ⅳ), 15 grams of formula (Ⅴ-1), 15 grams of (Ⅶ-2) and 250 grams of dispersant MF, after adding 850 grams of water and blending, grinding and dispersing and drying, the finished product is obtained. The dye can provide a blue hue with excellent wet handling properties for fabrics.

[0052]

[0053]

Embodiment 2~15

[0055] According to the method described in Example 1, the difference is to adopt the structure and weight of components A to D in Table 1, add 250 grams of auxiliary agents (200 grams of dispersant MF, and 50 grams of sodium lignosulfonate), add water After 850 grams of blending, it is made into a slurry, ground and dispersed, and dried to obtain a finished product. The dye can provide blue to black hues with excellent fastness properties to fabrics.

[0056] Table 1

[0057]

[0058]

Embodiment 16

[0064] Select the disperse dyes obtained in the above-mentioned Examples 1 to 15 and Comparative Examples 1 to 4, and use conventional high temperature and high pressure dyeing method and heat setting to process polyester fabrics. During the process, control the dyeing depth (o.w.f) to 3.0%, and the liquor ratio to 1:50 , the pH value of the dyeing bath is 4-5, the dyeing is carried out at room temperature, the temperature is raised to 130°C at 1°C / min, and the temperature is kept for 60 minutes, and the normal method is used to restore and wash, wash with water, dry, and heat-set at 200°C for 1 minute and 30 seconds to obtain the dyed fabric . According to ISO105-X12 and ISO105-C10, respectively test the color fastness to rubbing and soaping, the results are shown in the following table 2:

[0065] Table 2

[0066]

[0067]

[0068] It can be seen that the blue to black disperse dye composition in the present invention, after high-temperature heat setting treatment, ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com