Cotton fiber gray fabric modifying and dyeing method

A dyeing method and cotton fiber technology, applied in the field of cotton fabric dyeing, can solve the problems that the dyeing rate can only reach about 80%, the discharge of sewage is large, and the concentration of residual liquid is high. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) After scouring the cotton fiber gray cloth, add 1.5g / L refining enzyme 301L (Novozymes (China) Biotechnology Co., Ltd.), 8g / L biological modifier AS (Changzhou Meisheng Biotechnology Co., Ltd.), Among them, the bath ratio of cotton fiber gray cloth is 1:8, and the temperature is raised to 60°C for 30 minutes at a heating rate of 2°C / min. The modified cotton fiber gray cloth is obtained. The color fastness can meet the conventional fastness requirements, and the soaping fastness is also good. Can reach level 4 or higher.

[0025] (2) Wash the modified cotton fiber gray cloth obtained in step (1) for 10 minutes, add a blue medium-temperature reactive dye (concentration is 2% owf), heat up to 50 ° C and dye for 60 minutes, and the dyeing bath ratio is 1:6 , drain, then wash with water for 10 minutes, add color-fixing agent DS-7128 (Shanghai Desang Chemical Co., Ltd.) to fix the color for 10 minutes at 60°C to improve the fastness to wet treatment, wash with water for 1...

Embodiment 2

[0027] (1) After scouring the cotton fiber gray cloth, add 1.5g / L refining enzyme 301L (Novozymes (China) Biotechnology Co., Ltd.), 10g / L biological modifier AS (Changzhou Meisheng Biotechnology Co., Ltd.), Among them, the bath ratio of cotton fiber gray cloth is 1:8, and the temperature is raised to 60°C at a heating rate of 2°C / min for modification treatment for 30 minutes to obtain a modified cotton fiber gray cloth.

[0028] (2) Wash the modified cotton fiber gray cloth obtained in step (1) for 10 min, add red medium temperature reactive dye (concentration is 1.5% owf), heat up to 40° C. and dye for 45 min, the dyeing bath ratio is 1:6, Drain, then wash with water for 10 minutes, and soften for 10 minutes to obtain red cotton fiber dyed cloth with a dye uptake rate of over 98%.

Embodiment 3

[0030] (1) After scouring the cotton fiber gray cloth, add 1.5g / L refining enzyme 301L (Novozymes (China) Biotechnology Co., Ltd.), 10g / L biological modifier AS (Changzhou Meisheng Biotechnology Co., Ltd.), Among them, the bath ratio of cotton fiber gray cloth is 1:8, and the temperature is raised to 60°C at a heating rate of 2°C / min for modification treatment for 30 minutes to obtain a modified cotton fiber gray cloth.

[0031] (2) Wash the modified cotton fiber gray cloth that step (1) obtains for 10 min, add a yellow medium-temperature reactive dye (concentration is 1.5% owf), heat up to 40° C. and dye for 45 min, the dyeing bath ratio is 1:6, Drain, then wash with water for 10 minutes, and soften for 10 minutes to obtain yellow cotton fiber dyed cloth with a dye uptake rate of over 98%.

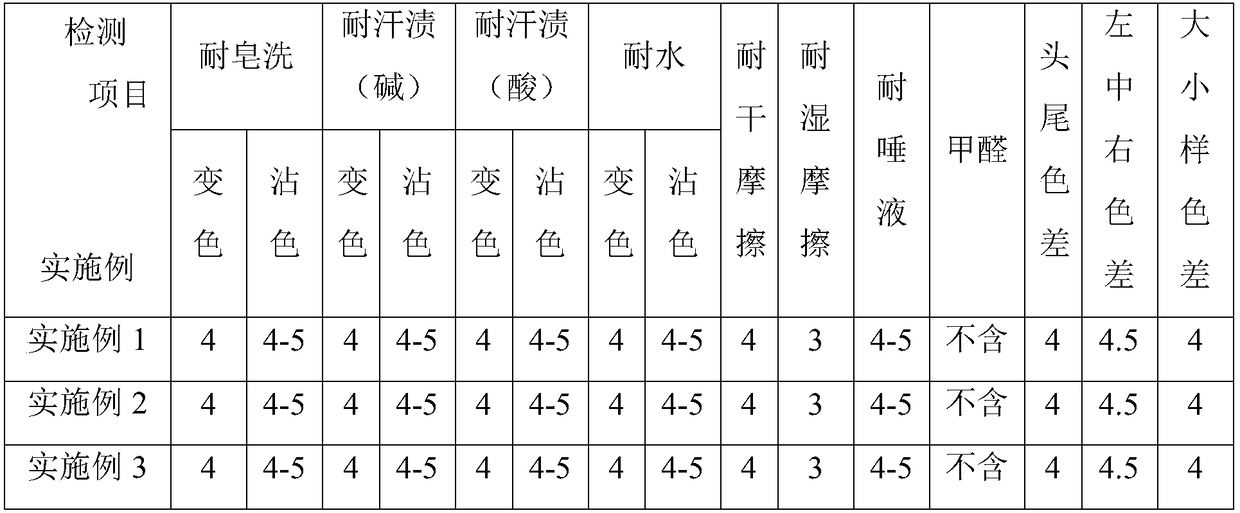

[0032] Three kinds of color cotton fiber dyed cloths that embodiment 1~3 obtain are detected, and detection result is as shown in table 1:

[0033] Table 1 Example 1~3 three kinds of col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com