Digital ink-jet printing method of low-urea silk fabric

A silk fabric and digital inkjet technology, which is applied in dyeing, animal fiber, textiles and papermaking, etc., can solve the problems of unsatisfactory effect and inability to get rid of pollution, so as to reduce the burden of sewage treatment, environmental protection and application effect, and good Effect of Wet Treatment Fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

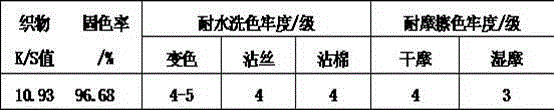

Embodiment 1

[0026] A kind of low urea real silk fabric digital inkjet printing method of the present embodiment comprises the following steps:

[0027] Fabric pretreatment→radiation drying→jet printing→steaming→cold water washing→hot water washing→soaping→hot water washing→cold water washing→stenter drying.

[0028] (1) Fabric pretreatment refers to the silk fabric after degumming and tentering, which is sizing on one side on the sizing machine. The size includes quaternary ammonium salt cationic modifier, guar gum, sodium bicarbonate, hygroscopic swelling agent, sodium sulfate and water, each composed as follows by weight percentage:

[0029] Quaternary ammonium salt cationic modifier 3%

[0030] Guar Gum 6%

[0031] Sodium bicarbonate 3%

[0033] Hygroscopic swelling agent 8%

[0034] The balance is water

[0035] Wherein, the hygroscopic swelling agent is urea and triethylene glycol with a mass ratio of 2:8.

[0036] (2) Dry the silk fabric pretreated ...

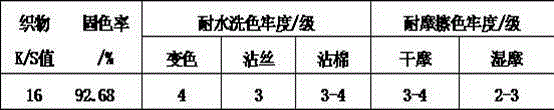

Embodiment 2

[0045] A kind of low urea real silk fabric digital inkjet printing method of the present embodiment comprises the following steps:

[0046] Fabric pretreatment→radiation drying→jet printing→steaming→cold water washing→hot water washing→soaping→hot water washing→cold water washing→stenter drying.

[0047] (1) Fabric pretreatment refers to the silk fabric after degumming and tentering, which is sizing on one side on the sizing machine. The size includes quaternary ammonium salt cationic modifier, guar gum, sodium bicarbonate, hygroscopic swelling agent, sodium sulfate and water, each composed as follows by weight percentage:

[0048] Quaternary ammonium salt cationic modifier 6%

[0049] Guar Gum 5%

[0050] Sodium bicarbonate 5%

[0051] Sodium Sulfate 2%

[0052] Hygroscopic swelling agent 6%

[0053] The balance is water

[0054] Wherein, the hygroscopic swelling agent is that the mass ratio of urea to glycerol is 3:7.

[0055] (2) Dry the silk fabric pretreated in ste...

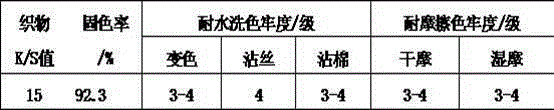

Embodiment 3

[0064] A kind of low urea real silk fabric digital inkjet printing method of the present embodiment comprises the following steps:

[0065] Fabric pretreatment→radiation drying→jet printing→steaming→cold water washing→hot water washing→soaping→hot water washing→cold water washing→stenter drying.

[0066] (1) Fabric pretreatment refers to the silk fabric after degumming and tentering, which is sizing on one side on the sizing machine. The size includes quaternary ammonium salt cationic modifier, guar gum, sodium bicarbonate, hygroscopic swelling agent, sodium sulfate and water, each composed as follows by weight percentage:

[0067] Quaternary ammonium salt cationic modifier 15%

[0068] Guar Gum 12%

[0069] Sodium bicarbonate 6%

[0070] Sodium Sulfate 6%

[0071] Hygroscopic swelling agent 10%

[0072] The balance is water

[0073] Wherein, the hygroscopic swelling agent is triethylene glycol and glycerol with a mass ratio of 1:7.

[0074] (2) Dry the silk fabric pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com