Method for dyeing cotton fabric with green by means of natural pigments

A technology of natural pigments and cotton fabrics, applied in dyeing, textile and papermaking, etc., can solve the problems of low utilization rate of dyes, poor wet fastness, poor light fastness, etc., and achieve poor light fastness, good coloring strength, Strong tinting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

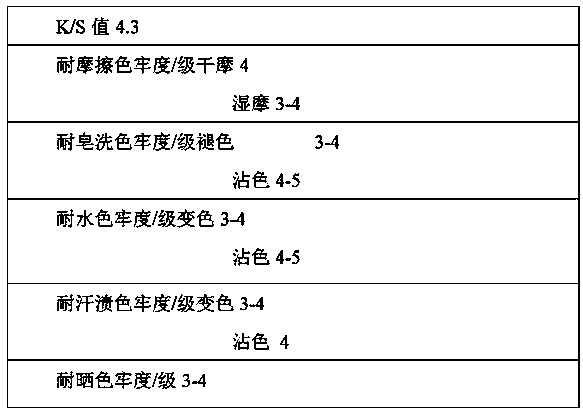

Embodiment 1

[0018] Utilize natural pigment of the present embodiment to dye the back mordant dyeing method of green cotton fabric, step is as follows:

[0019] (1) Put the cotton fabric wetted by warm water into 40℃ containing gardenia yellow pigment 0.5% (owf), gardenia blue pigment 0.4% (owf), myrobalan extract (Henan Zhongda Hengyuan Biotechnology Co., Ltd. ) in 0.5% (owf) dyeing solution, bath ratio 1:30, heat up to 60°C at a heating rate of 2°C / min, keep warm for 20 minutes, add sodium chloride 10g / L to fully dissolve, and continue dyeing for 20 minutes;

[0020] (2) Put the dyed cotton fabric into a mordant solution containing 1% cerium chloride (owf) at 40°C, bath ratio 1:30, heat up to 60°C at a heating rate of 2°C / min, and keep warm for mordant dyeing for 30 minutes;

[0021] (3) Washing, neutral soaping, water washing, dehydration, natural drying or drying of the mordant cotton fabric. Namely: wash in cold water, wash in warm water at 50~60°C, soap wash with 3g / L neutral deterg...

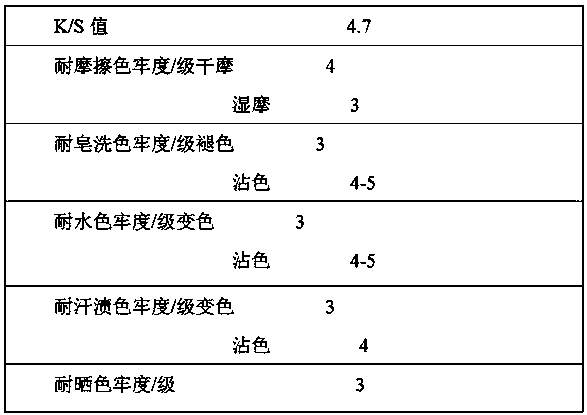

Embodiment 2

[0023] Utilize natural pigment of the present embodiment to dye the back mordant dyeing method of green cotton fabric, step is as follows:

[0024] (1) Put the cotton fabric wetted by warm water into the dye solution containing 2.5% (owf) of gardenia yellow pigment, 3.5% (owf) of gardenia blue pigment and 1.5% (owf) of chebula extract at 40°C, bath Ratio 1:20, heat up to 70°C at a heating rate of 2°C / min, keep dyeing for 30 minutes, add sodium chloride 30g / L to fully dissolve, and continue dyeing for 30 minutes;

[0025] (2) Put the dyed cotton fabric into a mordant solution containing 4% alum (owf) at 40°C, bath ratio 1:20, heat up to 70°C at a heating rate of 2°C / min, and keep mordant for 50 minutes;

[0026] (3) Washing, neutral soaping, water washing, dehydration, natural drying or drying of the mordant cotton fabric.

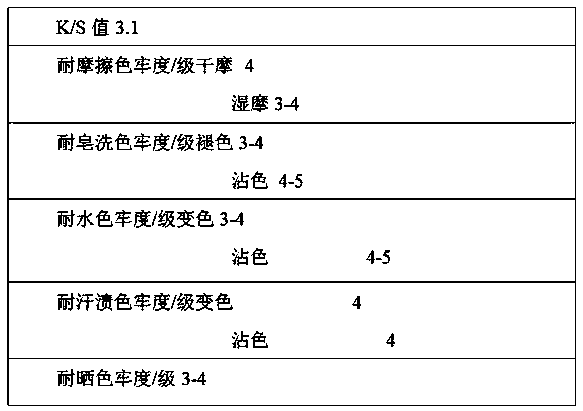

Embodiment 3

[0028] Utilize natural pigment of the present embodiment to dye the back mordant dyeing method of green cotton fabric, step is as follows:

[0029] (1) Put the cotton fabric wetted by warm water into the dye solution containing 2% gardenia yellow pigment (owf), gardenia blue pigment 2% (owf), and myrobalan extract 1% (owf) at 40 °C, bath Ratio 1:25, heat up to 65°C at a heating rate of 2°C / min, keep warm for 25 minutes, add sodium sulfate 20g / L to fully dissolve, and continue dyeing for 25 minutes;

[0030] (2) Put the dyed cotton fabric into a mordant solution containing 3% lanthanum chloride (owf) at 40°C, bath ratio 1:25, heat up to 65°C at a heating rate of 2°C / min, and keep mordant for 40 minutes;

[0031] (3) Washing, neutral soaping, water washing, dehydration, natural drying or drying of the mordant cotton fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com