Composite active black dye

A technology of reactive black and dyes, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of not reaching the degree of deep black, easy precipitation, color flowers, etc., and achieve excellent fastness and color fastness The effect of good degree and high fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

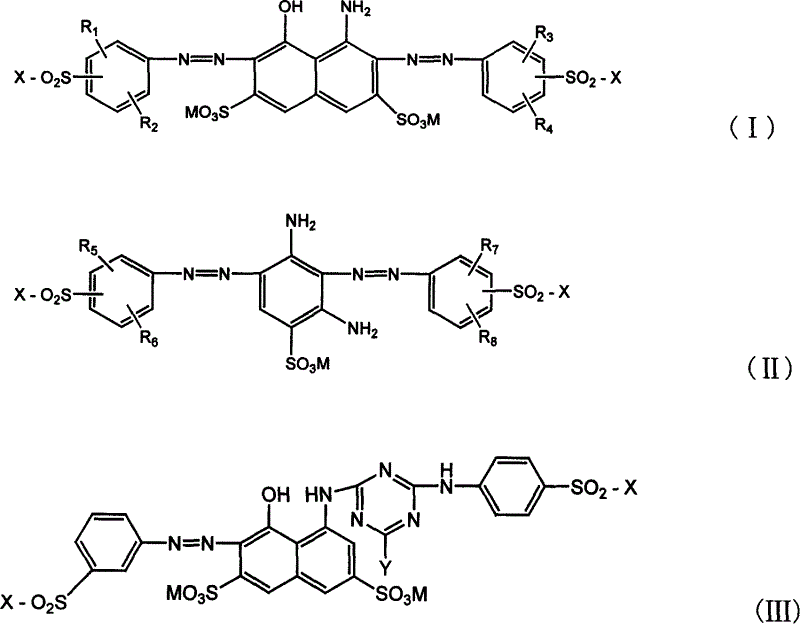

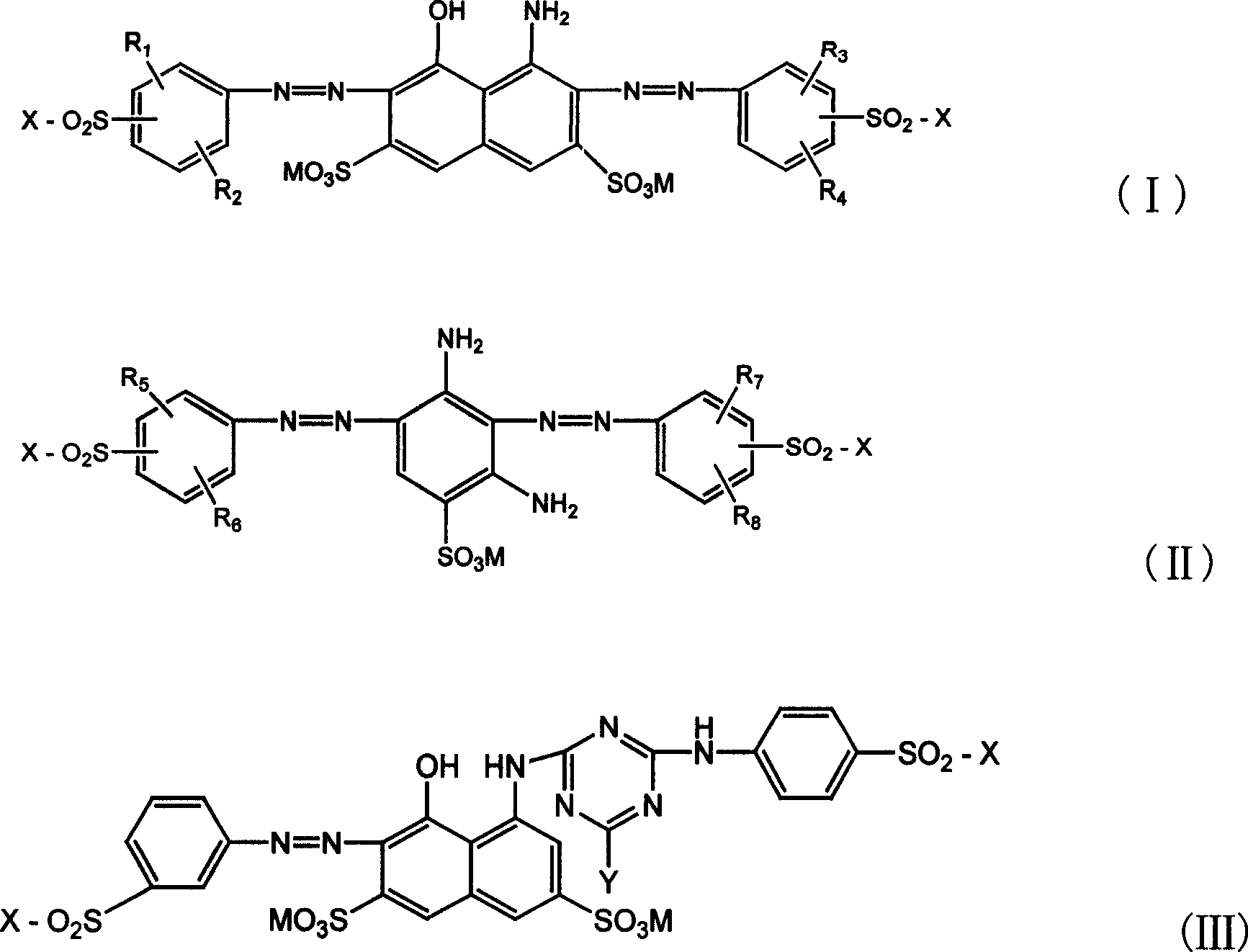

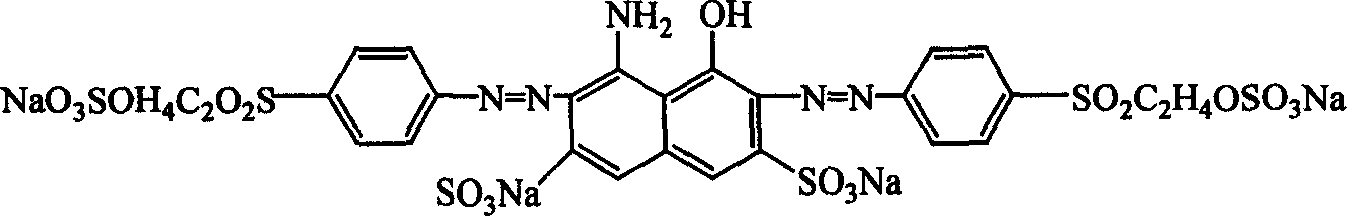

[0027] The structural formula of dye A is as follows:

[0028]

[0029] The structural formula of dye B is as follows:

[0030]

[0031] The structural formula of dye C is as follows:

[0032]

[0033] According to the measurement data shown in Table 1, dye A, dye B and dye C, filler sodium sulfate (industrial sodium sulfate), dispersant MF (methylnaphthalenesulfonic acid formaldehyde condensate), diffusing agent CNF (benzylnaphthalene Sulfonate formaldehyde condensate), diffusing agent NNO (naphthalenesulfonic acid formaldehyde condensate) blended, stirred evenly, and then spray-dried to obtain composite reactive black dye.

[0034]

Embodiment 9~17

[0036] According to the substituents and metering data shown in Table 2, dye A, dye B, dye C and auxiliary agent repeat the preparation steps described in Examples 1-8 to obtain composite reactive black dyes respectively.

[0037] raw material

Dye A

Dye B

Dye C

Yuan Ming

pink

(gram)

Dispersant

MF

(gram)

(gram)

(gram)

(gram)

R 1

R 2

R 3

R 4

R 5

R 6

R 7

R 8

X

M

Y

implement

Example 9

30

H

H

D

H

17

H

H

D

H

12

F

Na

Cl

10

0

implement

Example 10

34.5

H

H

E

H

24

M

D

H

H

18

F

Na

Cl

0

0

impleme...

Embodiment 18

[0042] Each get 1 gram of the composite reactive black dye that embodiment 1~17 makes is placed in the volumetric flask of 250ml and is mixed with uniform solution. Take 20ml and mix it with 120ml of distilled water in a dye vat, and add 50ml of 20% sodium sulfate solution to make a dye solution. Dip 2 grams of cotton cloth into the dye solution, heat it to 60°C under normal temperature and pressure, and absorb it for 30 minutes, then add 10ml of 20% sodium carbonate solution into the dye vat to fix the color of the cotton cloth. Fix the color in the sample machine for 45 minutes, take it out after dyeing, fully wash with water and wring dry, boil in soap solution containing 3 g / L of soap flakes for 15 minutes, wash and wring dry, dry at 60-70°C for sampling. Observe its color; adopt the methods determined in GB / T 3920-1997, GB / T 3922-1997 and GB / T 5713-1997 to test its color fastness to rubbing, color fastness to perspiration, and color fastness to water. The test results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com