Middle-temperature type disperse dye compound and preparation method and application thereof

A technology of disperse dyes and compounds, applied in chemical instruments and methods, dyeing methods, azo dyes, etc., can solve the problem of less varieties of medium-temperature disperse dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

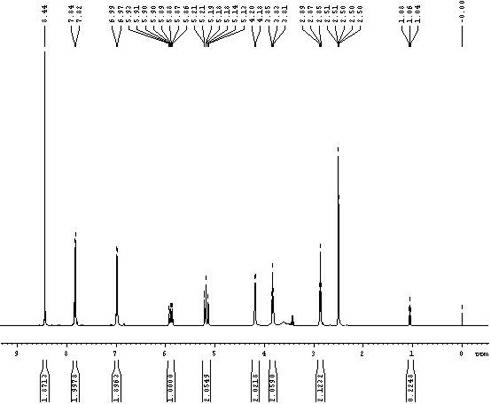

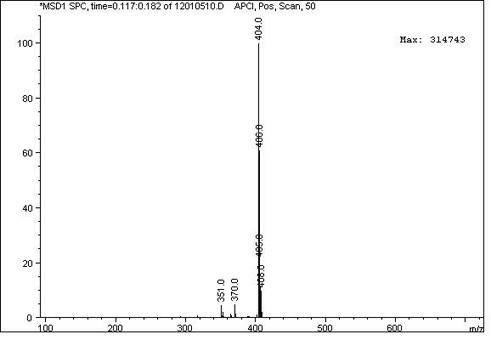

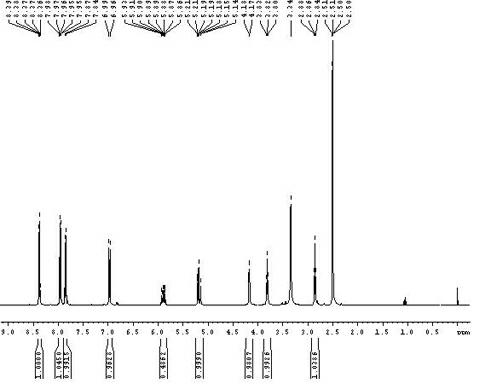

Image

Examples

Embodiment 1

[0071] (1) Add 78.8ml of water, 20.3g of aniline, 14.4g of acrylonitrile, 0.3g of hydroquinone and 0.75g of 30% hydrochloric acid to the autoclave. After adding, close the equipment, start the magnetic stirring, and heat up to 100°C evenly. , and keep the temperature at 100 ° C for 20 to 22 hours, the pressure is 0.25 MPa, after keeping the temperature to 45-50 ° C for half an hour, then slowly cool down to below 28 ° C, filter, the mother liquor water is recovered, the filter cake is washed with water, After drying, 30 g of intermediate B cyanoethylaniline was obtained.

[0072] Add 22.3 ml of water, 21.7 g of cyanoethylaniline, 5.6 g of magnesium hydroxide, 0.15 g of hydroquinone and 12.5 g of chloropropene into the autoclave. After adding, close the equipment, start the magnetic stirring, and evenly heat up to 100 ° C for 12 h , the pressure is 0.3MPa, then the temperature is slowly lowered to below 20℃, filtered, and the filter cake is washed with water and dried to obtain...

Embodiment 2

[0078] (1) Add 110ml of water, 27g of aniline, 17g of acrylonitrile, 0.55g of hydroquinone and 1.3g of 30% hydrochloric acid to the autoclave. After adding, close the equipment, start the magnetic stirring, and heat up to 100°C evenly. The temperature was kept at 100°C for 22 hours, and the pressure was 0.25MPa. After keeping, the temperature was lowered to 45-50°C for half an hour, and then slowly lowered to below 28°C, filtered, and the mother liquor was recovered. The filter cake was washed with water and dried to obtain 40 g of intermediate B cyanoethylaniline.

[0079] Add 63.5 g of methyl chloroacetate, 21.7 g of cyanoethylaniline, and 13.7 g of sodium bicarbonate to the there-necked flask, start stirring, uniformly heat up to 120 °C for 12 hours, then slowly cool down to below 20 °C, filter, and the filter cake is washed with water, After drying, 30.7 g of intermediate A-c was obtained, and the structural formula of intermediate A-c was (A-c).

[0080] (A-c) ...

Embodiment 3

[0084] (1) Add 52.5ml of water, 17.3g of aniline, 11g of acrylonitrile, 0.3g of hydroquinone and 0.8g of 30% hydrochloric acid to the autoclave. After adding, close the equipment, start the magnetic stirring, and heat up to 100°C evenly. And keep the temperature at 100°C for 20-22 hours, the pressure is 0.25MPa, after keeping it cool down to 45-50°C for half an hour, then slowly cool down to below 28°C, filter, recover the mother liquor, and the filter cake is washed and dried Then, 25 g of intermediate B cyanoethylaniline was obtained.

[0085] Add 30ml of water, 21.7g of cyanoethylaniline, 3.5g of magnesium oxide, 0.15g of hydroquinone and 15g of chloropropene into the autoclave. After adding, close the equipment, start the magnetic stirring, and evenly heat it to 100°C for 12h. The pressure is 0.3MPa, then slowly cooled to below 20°C, filtered, and the filter cake was washed with water and dried to obtain 26g of intermediate A-a of structural formula (A-a).

[0086] (2) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com