Glass-packaged diode detecting and labeling device

A glass packaging and testing device technology, applied in semiconductor/solid-state device testing/measurement, electrical components, program control in sequence/logic controllers, etc., can solve the problem of increased labor intensity, large demand, and low production efficiency problems, to achieve the effect of reducing labor intensity, high degree of automation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

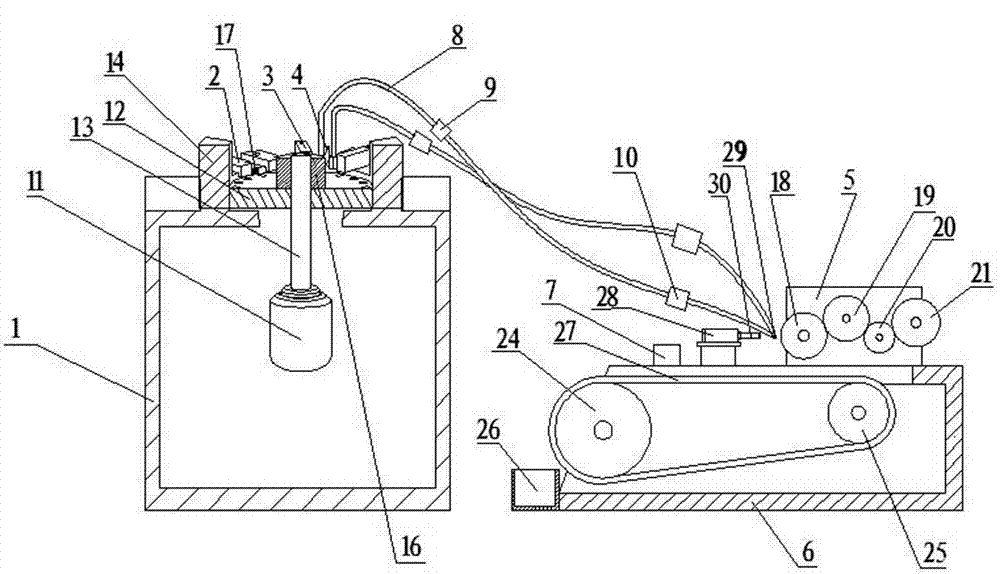

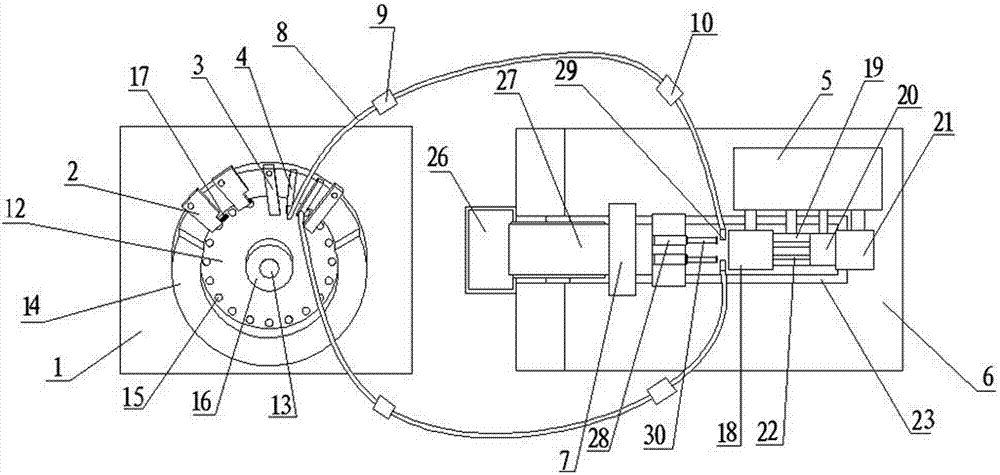

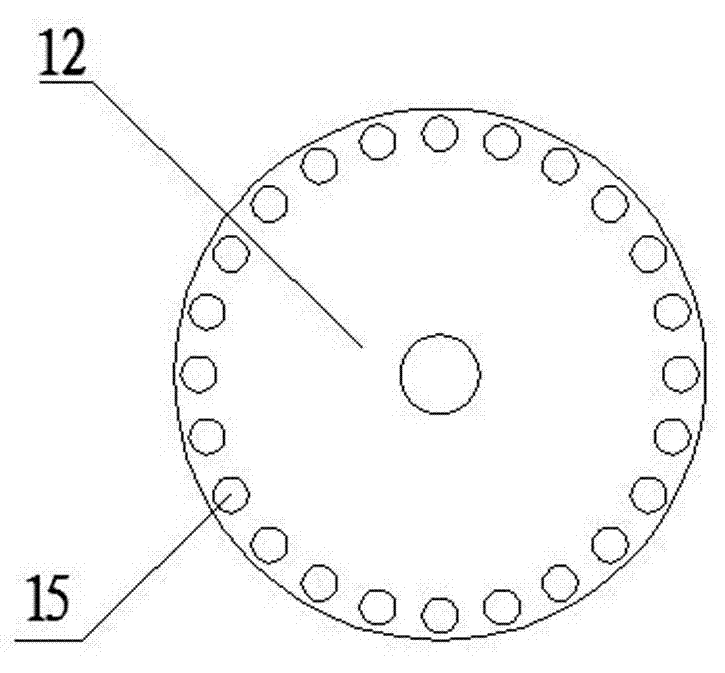

[0023] Such as figure 1 and figure 2 As shown, a glass-encapsulated diode detection and labeling device includes a PLC control cabinet 1, a detection device 2, a waste product removal device 3, a qualified product discharge device 4, a chassis 5, a working platform 6, an oven 7, and a material guide tube 8. The upper sensor 9 and the lower sensor 10, the upper surface of the PLC control cabinet 1 is an inclined plane, the servo motor 11 is perpendicular to the upper surface of the PLC control cabinet 1 and installed in the PLC control cabinet 1, and the turntable 12 is installed on the main shaft 13 of the servo motor 11 Above, the upper surface of the PLC control cabinet 1 is provided with an open circular retaining ring 14, the turntable 12 is arranged in the open circular retaining ring 14, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com