Dyeing method of chinlon

A nylon and fabric dyeing technology, applied in the field of nylon dyeing, can solve the problems of complex realization, ineffective improvement of color fastness, high requirements for chemical composition measurement, etc., and achieve the effects of process control, process stability, and high color fastness to washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

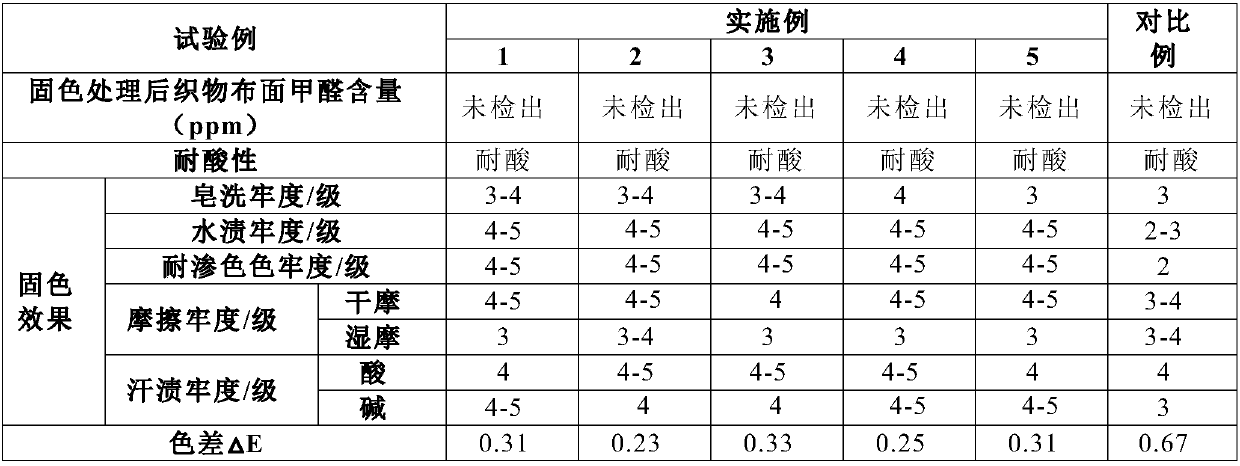

Examples

Embodiment 1

[0028] 1. 500kg nylon fabric is soaked in the first dye liquor that every liter contains 1.0gHT-33N and 0.05g SunacidOrange GSN (the total weight of the acid dye is 0.05% of the fabric weight), add 1M hydrochloric acid to adjust the pH to 4.0, Then treat at a temperature of 98°C for 40 minutes, and then cool down to below 60°C to discharge the liquid;

[0029] ② Soap the fabric treated in step ① at 40°C for 20 minutes and then drain;

[0030] ③Wash the fabric treated in step ② with water at room temperature first, and then perform acid color fixation at 60°C for 30 minutes after draining;

[0031] ④ Immerse the fabric treated in step ③ in hot water at 35°C containing polymers and wash it for 25 minutes. After draining, wash it with water at room temperature.

Embodiment 2

[0033] 1. Dip 500kg of nylon fabric into the first dye liquor containing 2.0gHT-33N and 3.0g Sunacid OrangeGSN (the total weight of the acid dyestuff is 0.5% of the fabric weight) per liter, add 2M hydrochloric acid agent to adjust the pH to 4.5 , and then treated at a temperature of 98°C for 30 minutes, and then cooled to below 60°C to discharge the liquid;

[0034] ② Soap the fabric treated in step ① at 40°C for 15 minutes before draining;

[0035] ③Wash the fabric treated in step ② with water at room temperature, drain the liquid, and then fix the color with acid at 65°C for 15 minutes;

[0036] ④ Immerse the fabric treated in step ③ in hot water at 35°C containing a special polymer and wash it for 25 minutes. After draining, wash it with water at room temperature.

Embodiment 3

[0038] 1. Dip 500kg of nylon fabric in the first dye liquor containing 1.8g HT-33N and 2.05g SunacidOrange GSN (the total weight of the acid dyestuff is 1.5% of the fabric weight) per liter, add 1.5M hydrochloric acid agent to adjust the pH 4.8, then treat at 100°C for 30 minutes, then cool down to below 60°C to drain;

[0039] ② Soap the fabric treated in step ① at 50°C for 18 minutes and then drain;

[0040] ③Wash the fabric treated in step ② with water at room temperature first, and then perform acid color fixation at 75°C for 20 minutes after draining;

[0041] ④Immerse the fabric treated in step ③ into hot water at 42°C containing a special polymer and wash it for 18 minutes. After draining, wash it with water at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com