Intelligent equipment for dyeing and sizing plurality of single yarns or plied yarns

A technology of intelligent equipment and yarn, which is applied to the equipment configuration of textile materials, the processing of textile materials, and the removal of liquid/gas/vapor by air jet method, which can solve the problems of poor dynamic response, uneven dyeing, and impermeability of dyeing. , to achieve the effect of accurate yarn position control, uniform yarn force and high dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

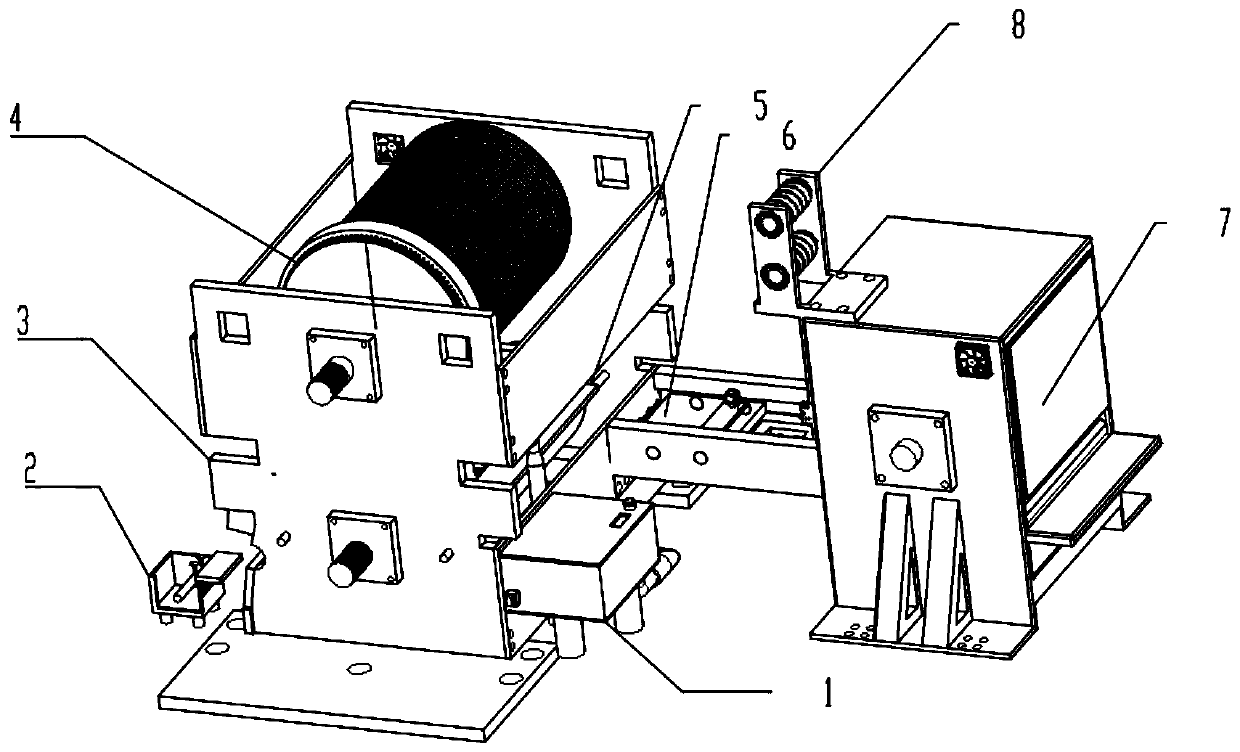

[0035] Such as figure 1 As shown, the present invention includes a dye liquor distribution heating cylinder 1, a yarn loader 2, a yarn tension pretensioner 3, an automatic dyeing and yarn arrangement mechanism 4, an automatic dyeing vat adjustment mechanism 5, an automatic sizing mechanism 6, and an automatic drying and yarn arrangement mechanism 7 and yarn collection guide 8.

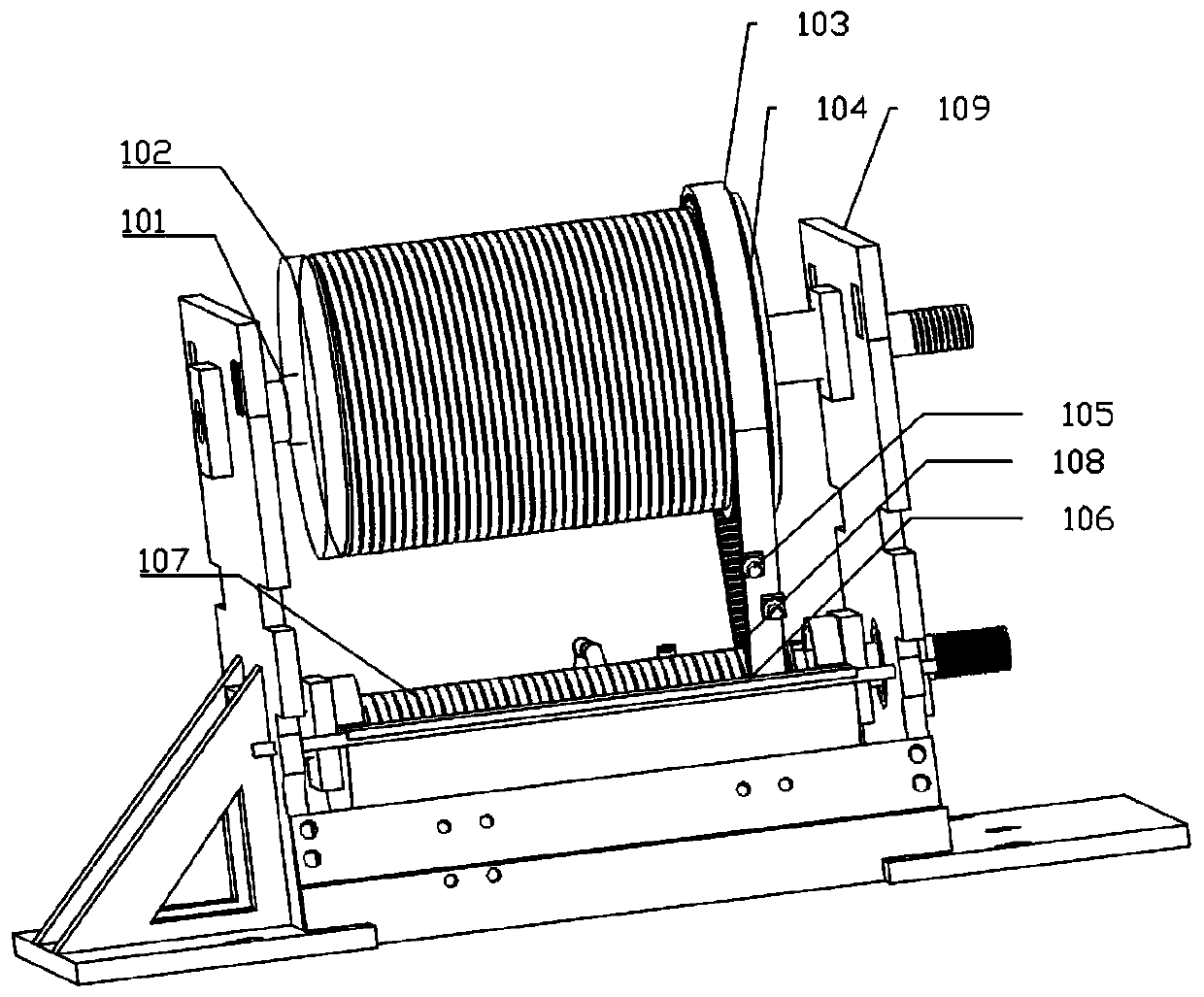

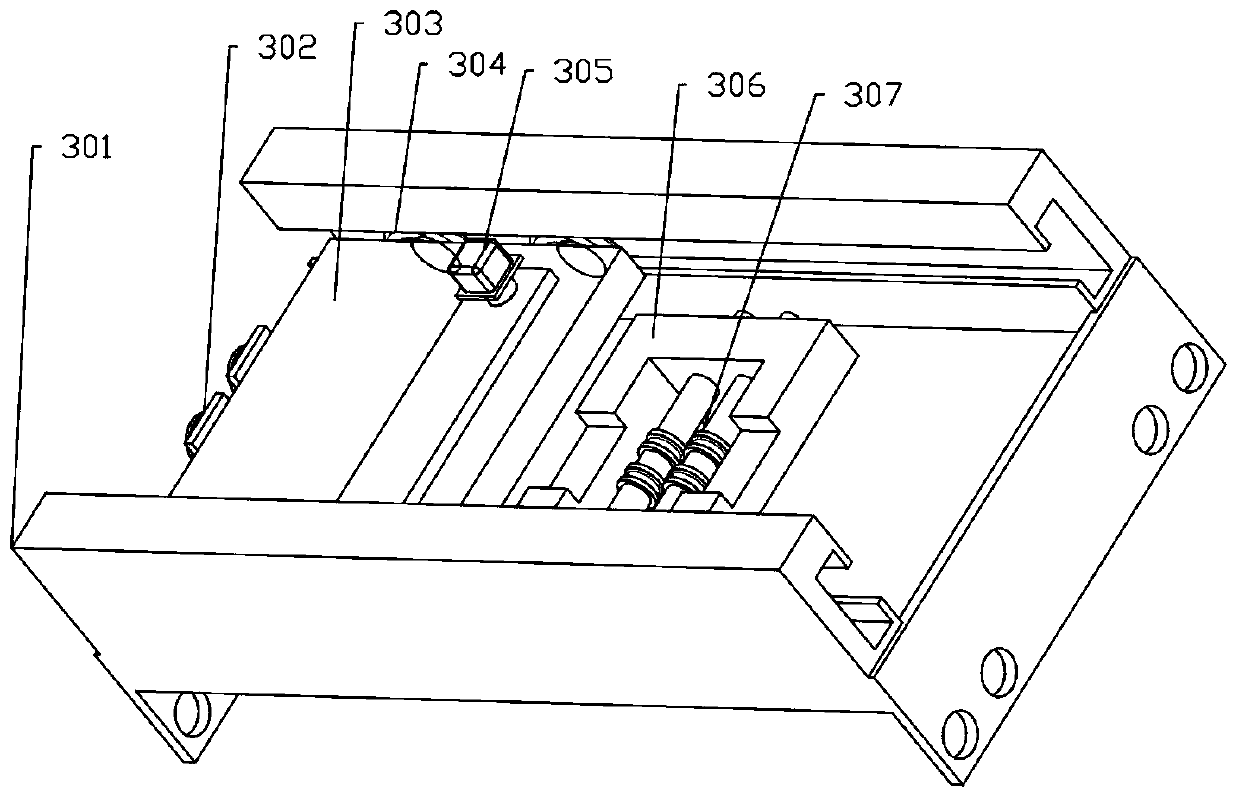

[0036] Such as figure 1 , 2 , 9, the described dye liquor distribution heating cylinder 1 comprises a dye liquor distribution heating cylinder housing 901, a liquid injection port 902, a dye injection port 903, a dye liquor output port 904, a dye liquor concentration and temperature detector 905, the dye liquor The liquid distribution heating cylinder housing 901 is a casting. A liquid injection port 902 and a dye injection port 903 are provided on the top of the dye liquor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com