Jet overflow dyeing machine nozzle

An overflow dyeing machine and nozzle technology, which is applied in textile processing machine accessories, textiles and papermaking, and textile material treatment at the outlet of textile materials. , to achieve the effect of preventing backflow, reducing "air drums" and reducing fabric kinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

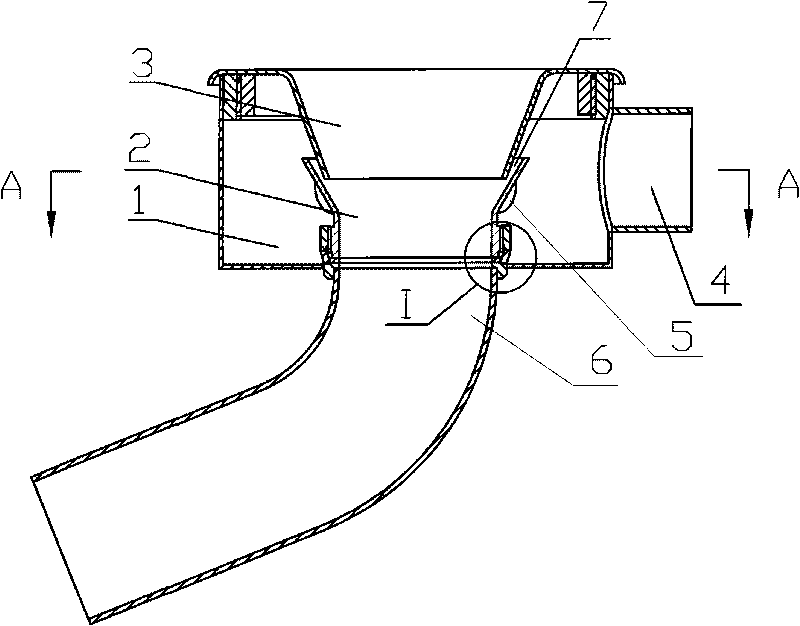

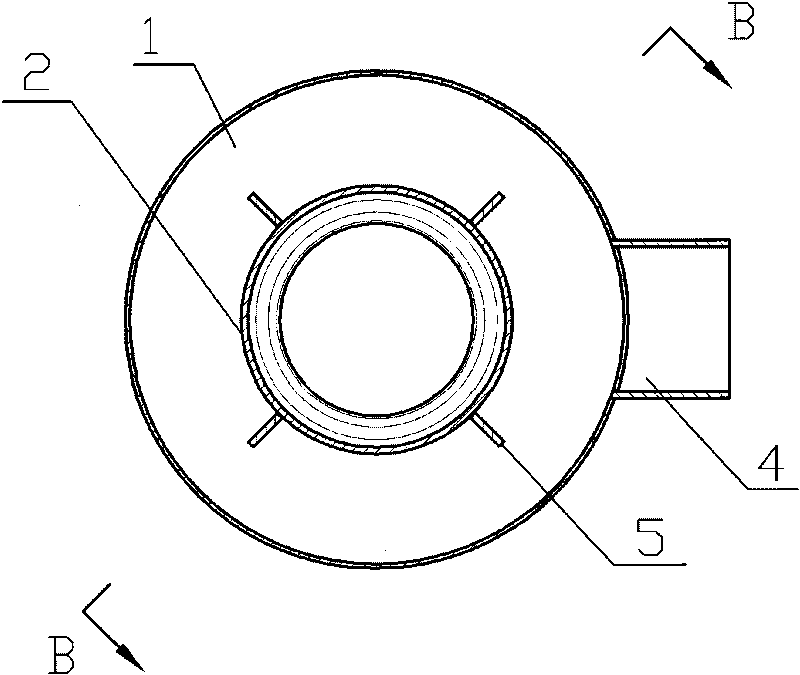

[0017] Such as Figure 1-5 A specific embodiment shown includes a nozzle seat 1 , a nozzle core seat 2 , a nozzle cover 3 , a nozzle liquid inlet pipe 4 , a water baffle 5 and a nozzle elbow 6 .

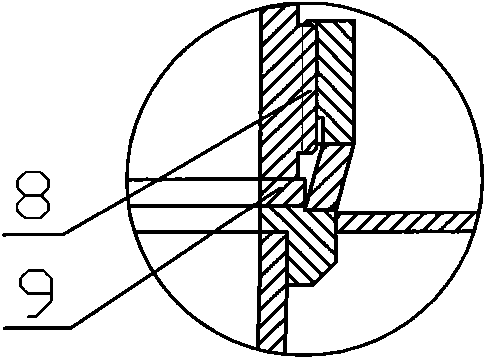

[0018] Such as figure 1 As shown, the nozzle core seat 2 and the nozzle cover 3 are arranged in the nozzle seat 1, the nozzle core seat 2 and the nozzle cover 3 are funnel-shaped, the lower end of the nozzle cover 3 is inserted in the nozzle core seat 2, the nozzle core seat 2 and the nozzle There is an annular gap between the covers 3, the annular gap is the dye solution injection inlet 7, and the side of the nozzle seat 1 is provided with a nozzle liquid inlet pipe 4. Such as figure 1 with figure 2 As shown, the bottom surface of the nozzle seat 1 is welded with a cylindrical lower support inserted on the bottom surface. The upper end of the cylindrical lower support is provided with an internal thread 8, and the middle part of the cylindrical lower support is fixed with a stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com