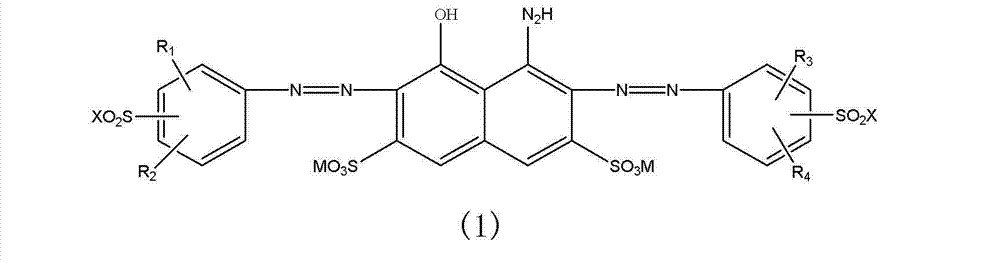

Composite dark black reactive dye

A reactive dye and dye technology, applied in the direction of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of large differences in hydrophilicity and lipophilicity, large differences in fiber affinity, and incompatibility of dyeing properties, and achieves the improvement of high efficiency. Dyeing rate and fixing rate, improving washing resistance, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

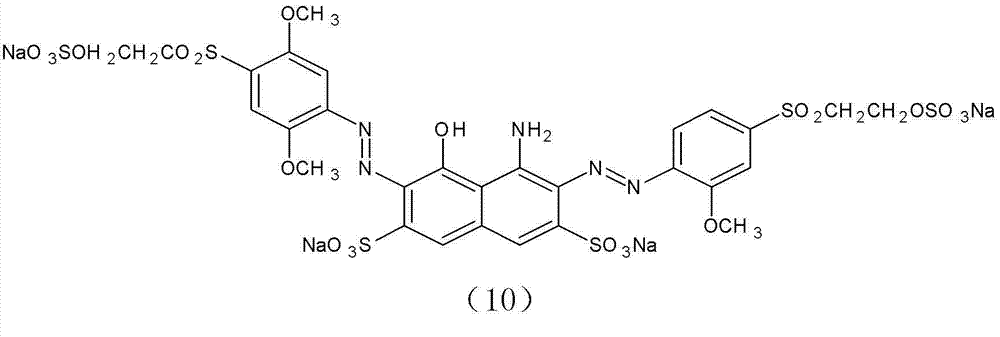

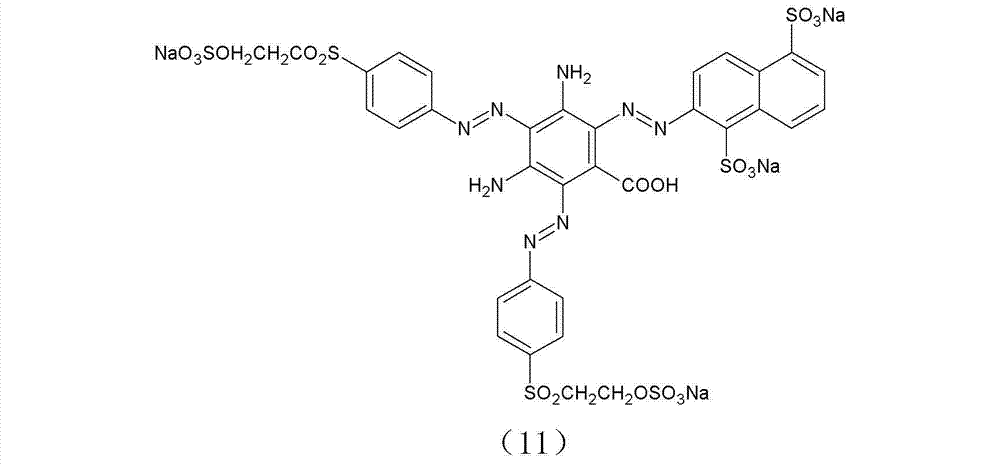

Examples

Embodiment 1

[0044] 1. Synthesis of formula (4) in reactive dye A:

[0045] 1. Diazo reaction: Add 29.5 g of p-(β-sulfate ethyl sulfone) aniline, (that is, the para-ester) into 100 ml of water and 50 g of crushed ice solution for beating for 1 hour. Then add 13.5g of hydrochloric acid (30%), stir for 1 minute, slowly add 24.3g of dissolved 30% sodium nitrite dropwise to the beaten para-ester for diazotization reaction, and control the temperature during the dropwise addition 8-15℃, pH value control 1-1.2. And make the starch potassium iodide test paper microscopically blue, and the Congo red test paper microscopically blue. After the sodium nitrite solution is added dropwise, keep the temperature at 8-15°C, control the pH value at 1-1.2, stir and react for 30 minutes, and then balance the excess sodium nitrite with sulfamic acid. The reaction formula of the diazonium reaction is shown in the following formula (26).

[0046]

[0047] 2. Coupling reaction: Add 19.5 g of 1-amino-8-napht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com