Printing and dyeing process

A printing and dyeing process and dyeing solution technology, which is applied in dyeing, textile material processing, textiles and papermaking, etc., can solve the problems of poor color fastness, achieve good economic benefits, simple printing and dyeing process, and easy implementation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

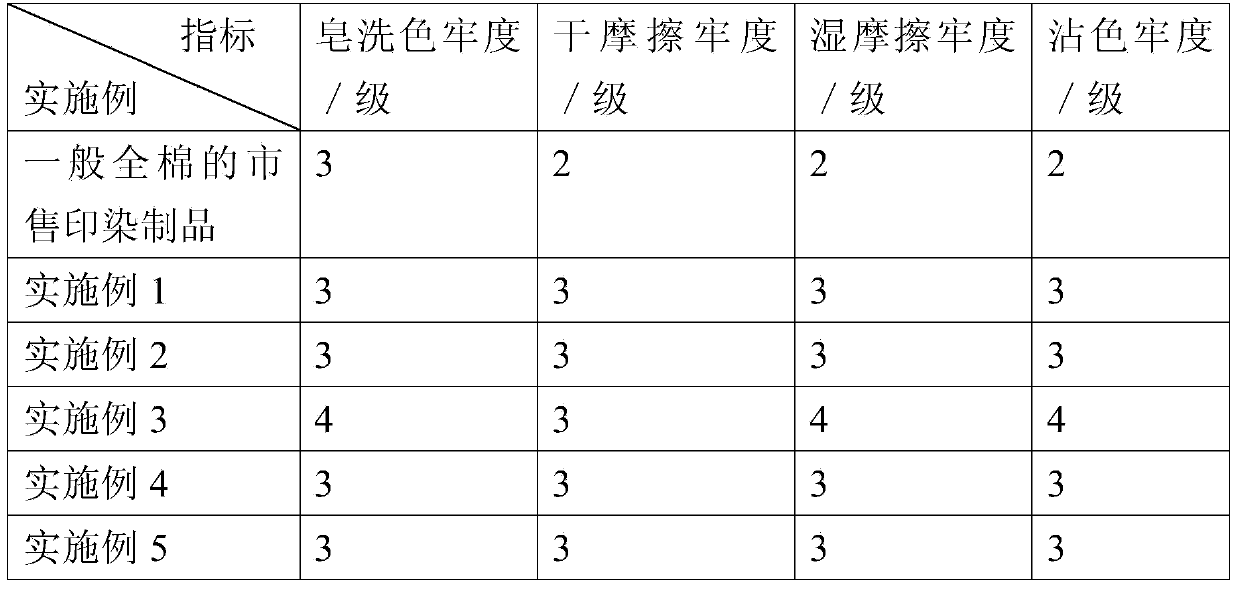

Embodiment 1

[0027] The YLD high-temperature and high-pressure air-flow atomization dyeing machine produced by Wuxi Yilida Chemical Printing and Dyeing Machinery Co., Ltd. is used.

[0028] The printing and dyeing process includes the following steps:

[0029] 1) Pre-treatment: put the cotton fabric in a singeing processor for singeing treatment, the conditions for singeing are: vehicle speed 80±2m / min, wind pressure 10±1mbar, burner through burning, gas pressure 0.11 ±0.01MPa, drying steam pressure is 0.1±0.05MPa, fire extinguishing steam box pressure is 0.02±0.01MPa, rolling car pressure is 0.3±0.05MPa, tension frame pressure is 0.4±0.1MPa, so that the obtained fabric singeing level 4 or more. Afterwards, the fabric is subjected to enzymatic desizing treatment, scouring and bleaching treatment. The working solution of enzymatic desizing treatment is penetrant JFC (Shangyu Chuangyu Chemical Co., Ltd.) and desizing enzyme TF-162D (Transfar Co., Ltd.) aqueous solution. The concentration o...

Embodiment 2

[0033]Basically the same as Example 1, the difference is that in step 3) of this example, before pre-baking, the dyed fabric is first immersed in a silane coupling agent-modified nano-silica deepening agent, dipped into Roll for 5min. The preparation method of the silane coupling agent-modified nano-silica deepening agent comprises the following steps: first dissolving nano-silica with an average particle diameter of 20nm (with a particle diameter range of 10-30nm) in ethanol to obtain nano-silica The weight percentage of silicon is 2.5% nano-silica ethanol dispersion, then add vinyltriethoxysilane (A-151) to the nano-silica ethanol dispersion, the added A-151 and nano-silica The mass ratio of nano-silica in the silicone alcohol dispersion is 10:100, react at 25°C for 24 hours, and obtain a silane coupling agent-modified nano-silica solution. The silane coupling agent-modified nano-silica solution is mixed with water at a mass ratio of 1:40 to obtain a silane-coupling agent-m...

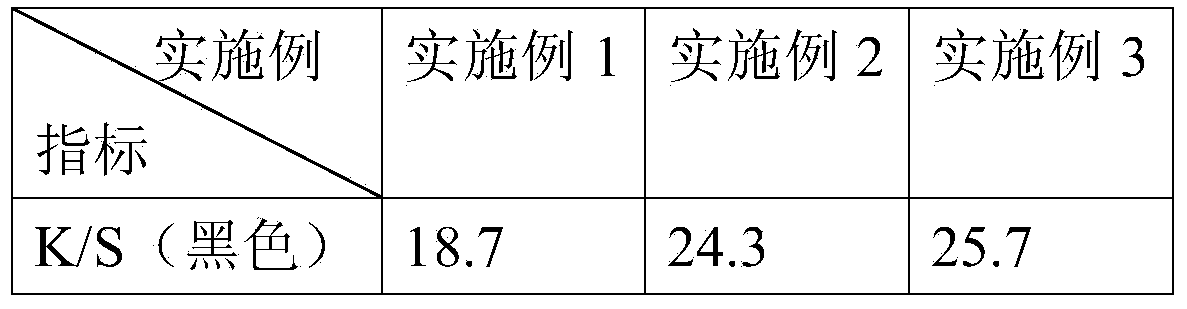

Embodiment 3

[0035] Basically the same as Example 2, the difference is that in step 3) of the present embodiment, before padding in the nano-silica deepening agent modified by silane coupling agent, padding in aqueous solution of crosslinking agent for 5min, crosslinking The aqueous linking agent solution contains 100g / L of crosslinking agent JF-694A (Wujiang Jinfeng Chemical Co., Ltd.) and 50g / L of softener JF-2010 (Jiashan Jiangnan Textile Material Co., Ltd.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com