An inkjet printing and dyeing process

An inkjet printing and dyeing technology, applied in dyeing, textile and papermaking, etc., can solve the problems of low affinity of reactive dyes, poor fiber-fabric binding, poor printing and dyeing stability, etc., to improve production efficiency and product quality, Good contact, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

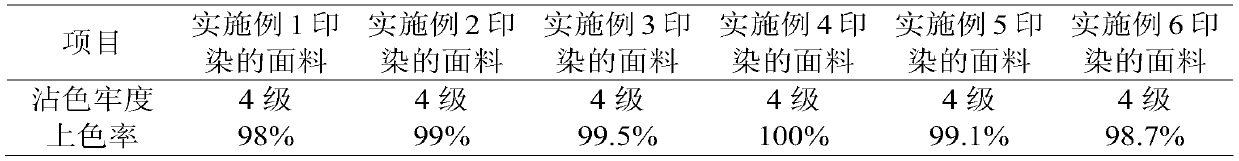

Examples

Embodiment 1

[0032] An inkjet printing and dyeing process, comprising the following steps:

[0033] Process A, prepare the raw materials for preparing inkjet dye solution, including: 15% of dichloro-s-triazine dyes, 10% of PA resin, 12% of imidazoline surfactant, 8% of n-propanol, and make up to 100% with water;

[0034] Step B, preparation of inkjet dyeing solution: pour the mass percentage of dichloro-s-triazine dyes, PA resin, and imidazoline surfactant into the water of the mass percentage, and stir for 30 min at a speed of 200 r / min , then add the n-propanol of the mass percentage, and stir for 30min at a speed of 800r / min to obtain an inkjet dye solution;

[0035] Process C, fabric salt treatment: the fabric is passed through the ammonium azide solution with a concentration of 2mol / L at a rate of 2m / s, and then dried at a temperature of 40°C for 1 hour to obtain a salt-treated fabric;

[0036] Process D, printing and dyeing: Add sulfuric acid and sodium hydroxide with a concentratio...

Embodiment 2

[0039] An inkjet printing and dyeing process, comprising the following steps:

[0040] Process A, prepare the raw materials for preparing the inkjet dye solution, including: 25% of thiamphenidine dyes, 5% of ABS resin, 5% of morpholine guanidine surfactants, 15% of isopropanol, and make up to 100% with water;

[0041] Step B, preparation of ink-jet dyeing solution: pour the mass percentage of thiamphenidine dyes, ABS resin, and morpholine guanidine surfactant into the water of the mass percentage, and stir at a speed of 400r / min 60min, add the isopropanol of described mass percentage again, stir 60min under the rotating speed condition of 1000r / min, obtain ink-jet dye liquor;

[0042] Process C, fabric salt treatment: the fabric is passed through the ammonium dichromate solution with a concentration of 4mol / L at a rate of 3m / s, and then dried at a temperature of 50°C for 3 hours to obtain a salt-treated fabric;

[0043] Process D, printing and dyeing: Add sulfuric acid and so...

Embodiment 3

[0046] An inkjet printing and dyeing process, comprising the following steps:

[0047] Process A, preparing raw materials for preparing ink-jet dye solution, including: 20% of dichloro-s-triazine dyes, 7.5% of AMMA resin, 8.5% of imidazoline surfactant, 11.5% of coconut oil, and water to make up to 100%;

[0048]Step B, preparation of ink-jet dyeing solution: pour the mass percentage of dichloro-s-triazine dyes, AMMA resin, and imidazoline surfactant into the water of the mass percentage, and stir for 45 min at a speed of 300 r / min , add the coconut oil of described mass percentage again, stir 45min under the rotating speed condition of 900r / min, obtain ink-jet dye liquor;

[0049] Process C, fabric salt treatment: pass the fabric through the ammonium fluorosilicate solution with a concentration of 3mol / L at a rate of 2.5m / s, and then dry it at a temperature of 45°C for 2 hours to obtain a salt-treated fabric ;

[0050] Process D, printing and dyeing: Add sulfuric acid and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com