Manufacturing method of stainable alginate fibers

A technology of alginate fiber and manufacturing method, which is applied in the direction of alginate rayon, rayon manufacturing, and fiber chemical characteristics, and can solve the problems of difficult alginate fiber dyeing, poor salt resistance and alkali resistance, etc. , to achieve the effects of increasing added value and market competitiveness, good color fastness, and excellent wet fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

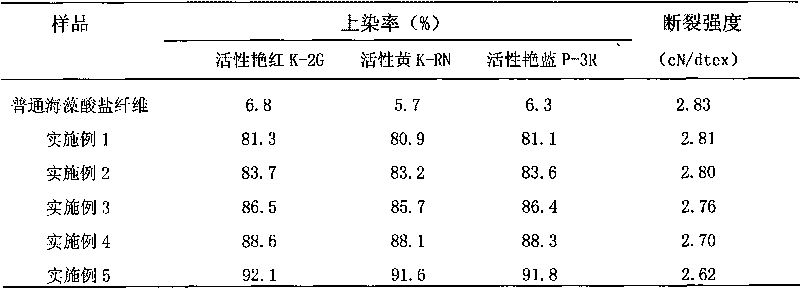

Examples

Embodiment 1

[0024] Weigh 1.2 grams of polyamidoamine dendrimers of the second generation (2.0 generations) and dissolve them in 960 ml of distilled water, then add 40 grams of sodium alginate, and mechanically stir at 25° C. for 4 hours to obtain a concentration of 4% by mass. The sodium alginate fiber spinning solution was filtered and defoamed under reduced pressure for 14 hours to obtain the sodium alginate fiber spinning solution. Under the action of pressure, the sodium alginate spinning stock solution enters the coagulation bath of calcium chloride aqueous solution with a temperature of 30°C and a concentration of 4% by mass through the metering pump and spinneret, and then it is drawn after solidification, and the fiber The drafting adopts three-stage drafting process, and each stage is drawn by 1.5 to 1.8 times, and then washed and dried to obtain dyeable sodium alginate fibers. In the above steps, the fiber washing temperature is 40°C, and the drying temperature is 60°C.

Embodiment 2

[0026] Take by weighing the polyamide-amine dendrimer compound of the second generation (2.0 generation) of 2.0 grams, be dissolved in 950ml distilled water, obtain polyamide-amine dendrimer aqueous solution, then add polyamide-amine dendrimer aqueous solution Add 50 grams of sodium alginate to the mixture, stir mechanically at 30°C for 3.5 hours to obtain a sodium alginate fiber spinning solution with a concentration of 5% by mass, filter the above-mentioned sodium alginate fiber spinning solution, and defoam under reduced pressure for 16 hours to obtain seaweed Sodium acid fiber spinning dope. Under the action of pressure, the sodium alginate fiber spinning stock solution enters the coagulation bath of barium chloride aqueous solution with a temperature of 40°C and a concentration of 5% by mass through the metering pump and spinneret, and then is drawn, washed, and dried in sequence. Then get dyeable sodium alginate fiber. In the above steps, the fiber is drawn using a thre...

Embodiment 3

[0028] Weigh 3.6 grams of the second-generation (2.0 generation) polyamide-amine dendrimers and dissolve them in 940 mL of distilled water, then add 60 grams of sodium alginate, and stir mechanically at 35° C. for 3.5 hours to obtain a polyamide-amine dendrimer with a mass percentage concentration of 6%. The sodium alginate fiber spinning solution was filtered and defoamed under reduced pressure for 18 hours to obtain the sodium alginate fiber spinning solution. Under the action of pressure, the sodium alginate fiber spinning stock solution enters the coagulation bath of aluminum chloride aqueous solution with a temperature of 45°C and a mass percentage concentration of 6% through a metering pump and a spinneret, and is obtained after coagulation, drawing, washing and drying. Sodium alginate fiber can be dyed. In the above steps, the fiber is drawn using a three-stage drawing process, each stage is drawn 1.7 to 2.0 times, the fiber washing temperature is 45°C, and the drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com