Active black dye

A reactive black and dye technology, applied in the field of reactive black dyes, can solve the problems of unsatisfactory washing fastness, increased dyeing cost for customers, low alkali resistance stability, etc., achieves excellent color fixing rate, reduces head and tail color difference, and dyes heavy. High visibility and dye uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

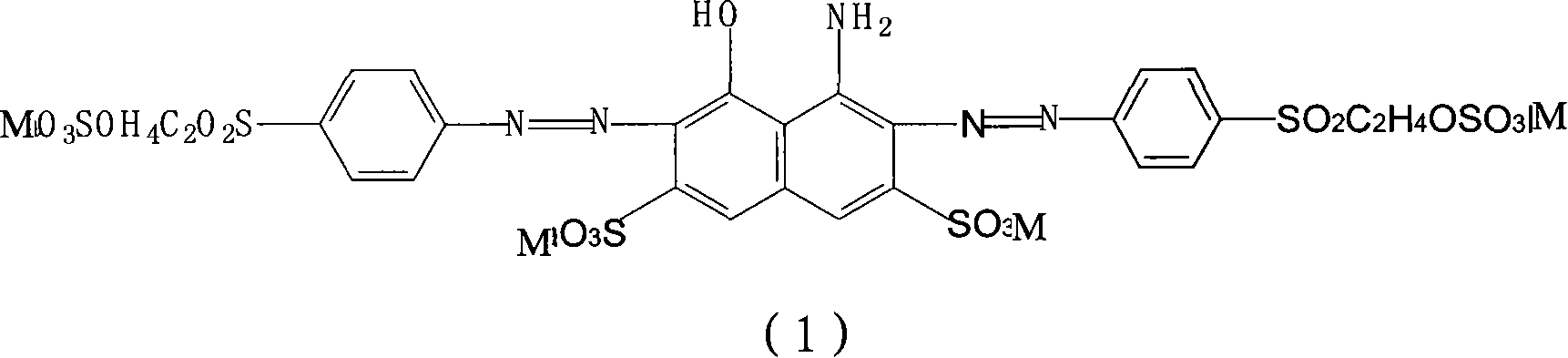

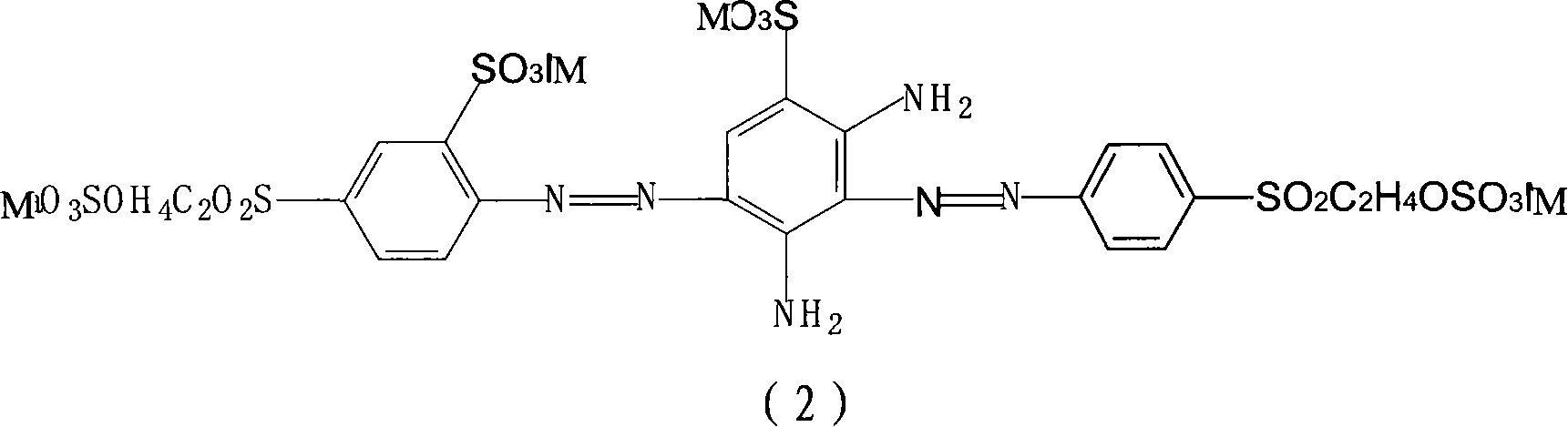

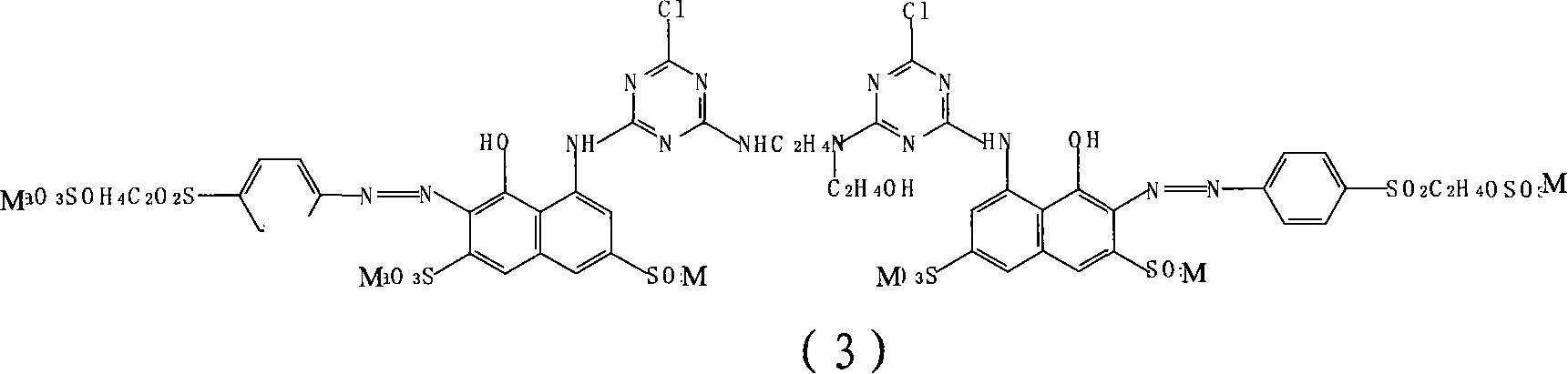

Method used

Image

Examples

Embodiment 1

[0038] Weigh 60 kg of Compound A (Black KN-B), 16 kg of Compound B (RD Yellow), 8 kg of Compound C (HW Red) and 14 kg of Yuanming powder, and 2 kg of Dispersant MF for dry blending by blender That is the reactive black dye of the present invention.

Embodiment 2

[0040] Weigh 65 kg of compound A (black KN-B), 12 kg of compound B (golden yellow), 10 kg of compound C (red) and 10.5 kg of Yuanming powder, and 2.5 kg of dispersant MF through a blender for dry blending. Reactive black dye of the present invention.

Embodiment 3

[0042] Weigh 78 kilograms of compound A (black KN-B), 18 kilograms of compound B (golden), and 4 kilograms of compound C (red) carry out dry blending by a blender to obtain the reactive black dye of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com