Continuous open-width cloth boiling high-temperature cleaning structure

A high-temperature, cloth-cooking technology, which is applied in the continuous processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc., can solve the problems of uneven dispersion of oil agents, easy scratches of fabrics, and long time, etc. Achieve the effect of saving production time, improving production efficiency and solving cylinder difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

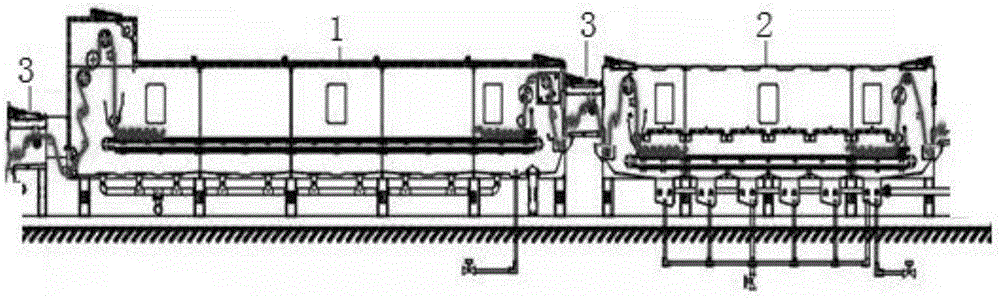

[0012] Such as figure 1 The shown continuous open-width boiled cloth high-temperature cleaning structure includes a high-temperature steamer 1, a washing water tank 2 and a group of small paddle cars 3, wherein a group of small paddle cars 3 are respectively arranged in the high-temperature steamer 1 on both sides; the high-temperature steamer 1 is a mesh-belt steamer; the washing tank 2 is a mesh-belt washing tank.

[0013] Further preferably, the high-temperature steamer 1 is steamed at a high temperature of 90°C-100°C for 8-30 minutes, so that the fabric and the auxiliary agent react rapidly at high temperature to achieve the bleaching effect of the cloth surface, which can be adjusted according to the thickness of the fabric. The speed of the mesh belt is used to set the size of the piled cloth; the fabric in the washing tank 2 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com