Preparation method of polyol copolyester

A technology of alcohol copolyester and polyol, which is applied in dyeing, textile and papermaking, etc., can solve the problem that polyester modified products cannot be produced quantitatively, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

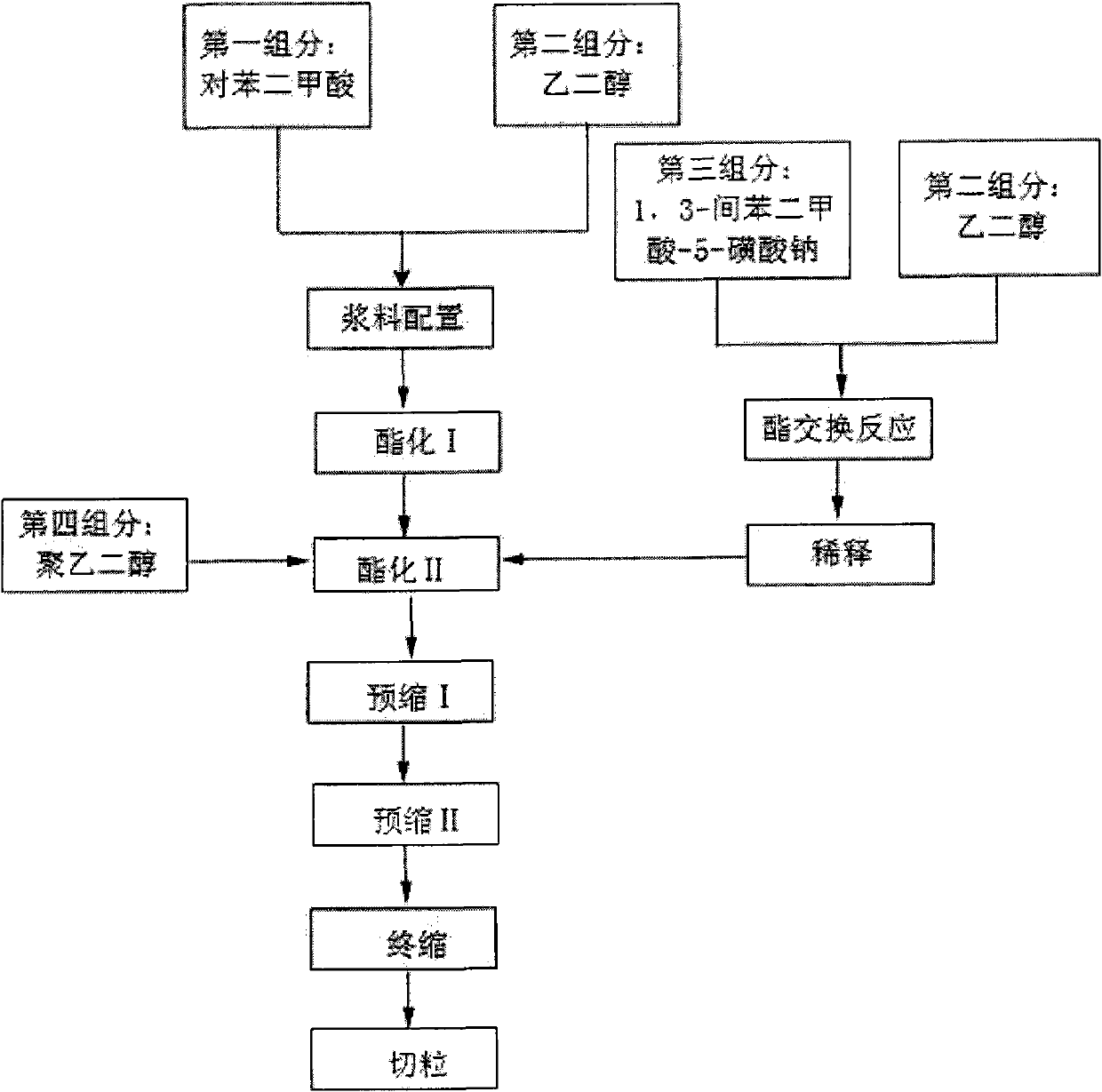

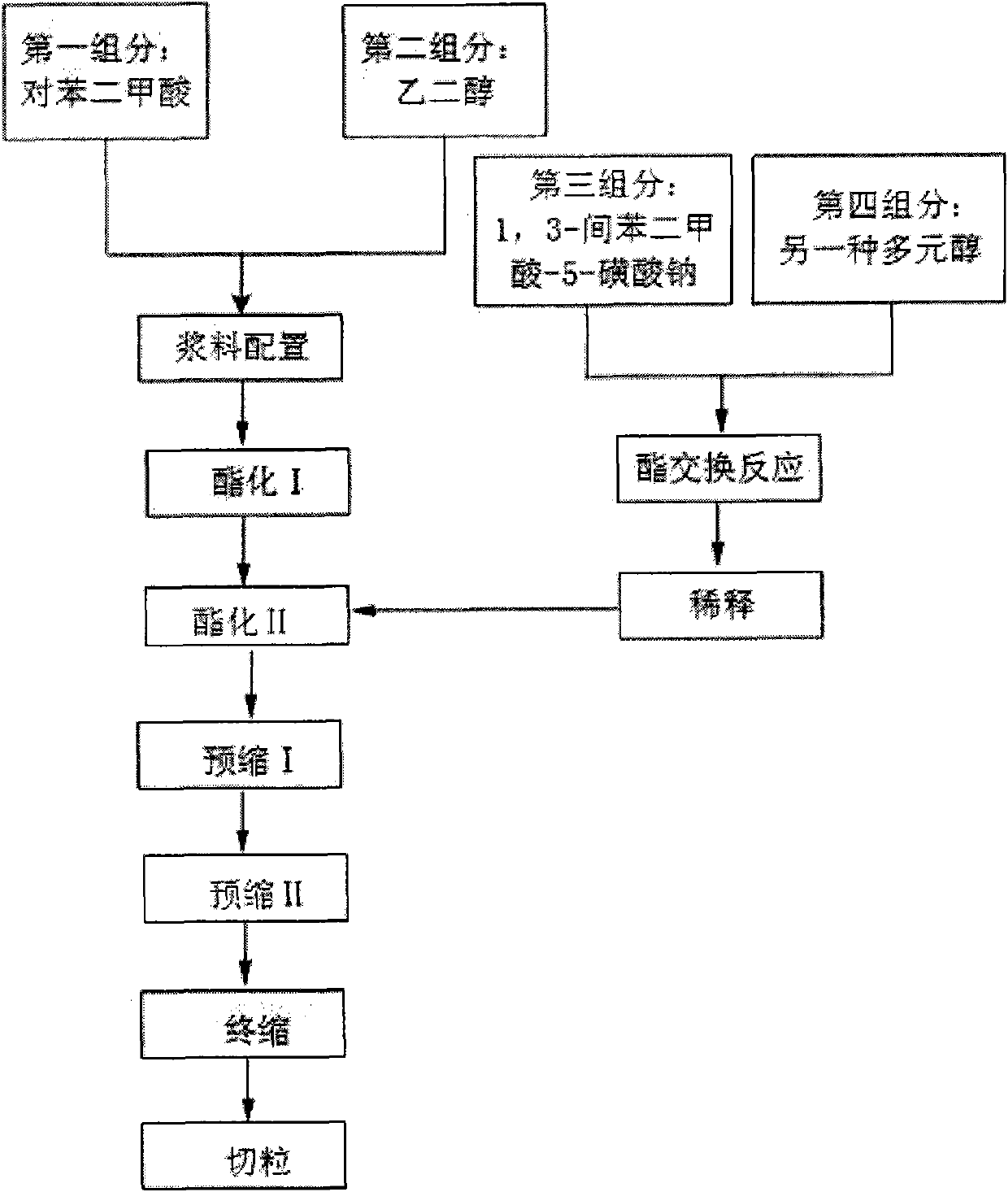

[0035] The preparation method of polyol copolyester of the present invention, as image 3 As shown, the production process is as follows: slurry configuration of terephthalic acid and ethylene glycol, esterification I, esterification II, preshrinkage I, preshrinkage II, final shrinkage and pelletizing steps, and 1,3- The isophthalic acid-5-sodium sulfonate is subjected to the transesterification reaction step with another polyol, and after the dilution step, it enters the above-mentioned esterification II step.

[0036] The details are as follows:

[0037] (1) Slurry configuration

[0038] The mass ratio of purified terephthalic acid to ethylene glycol is: 1:0.36~1:0.42;

[0039] Liquid level control: 60-80%;

[0040] Temperature: 40~60℃;

[0041] Residence time: 3~5h.

[0042] (2) Esterification I

[0043] Reaction temperature: 261~265℃;

[0044] The reaction time is 3~4h; the pressure is 50~65Kpa;

[0045] Liquid level 50-65%;

[0046]The ethylene glycol is refluxed...

Embodiment 1

[0088] A new type of normal temperature and pressure copolyester chip is being improved in production, and its process flow is as follows image 3 shown. Wherein, another polyhydric alcohol of the fourth component is neopentyl glycol.

[0089] First, the third component 1,3-sodium isophthalic acid-5-sulfonate and the fourth component neopentyl glycol are subjected to transesterification in advance, and the reaction equation is as follows:

[0090]

[0091] After reaching a transesterification rate of about 85%, it is sent to esterification II

[0092] Implementation process:

[0093] The specific reaction control process is as follows:

[0094] (1) Slurry configuration

[0095] Add purified terephthalic acid and ethylene glycol at the same time, wherein purified terephthalic acid is 10,000 kg / hour, ethylene glycol is 3,800 kg / hour, the liquid level is controlled at 60-80%, the temperature is 40-60°C, and the residence time is 3-60%. 5h.

[0096] (2) Esterification I ...

Embodiment 2

[0164] In ECDP improvement production, its technological process is as follows image 3 shown. Wherein, another polyhydric alcohol of the fourth component is polyethylene glycol PEG-200.

[0165] First, the third component 1,3-sodium isophthalic acid-5-sulfonate is transesterified with the fourth component polyethylene glycol PEG-200, and the reaction equation is as follows:

[0166]

[0167] After reaching a transesterification rate of about 85%, it is sent to esterification II.

[0168] Implementation process:

[0169] The specific reaction control process is as follows:

[0170] (1) Slurry configuration

[0171] Add 10,000 kg / hour of purified terephthalic acid, 3,800 kg / hour of ethylene glycol, control the liquid level at 60-80%, temperature 40-60°C, and residence time 3-5 hours.

[0172] (2) Esterification I

[0173] The reaction temperature is 261-265° C., the reaction time is 3-4 hours, the pressure is 50-65 Kpa, the liquid level is 50-65%, and the reflux of eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com